Buy Custom Wire Harness: Defining Requirements

Before beginning your search for suppliers in the market, it is essential to clearly define your procurement requirements and prepare the necessary documentation.

Defining Procurement Requirements and Technical Specifications

Clear procurement requirements and well-defined product details form the foundation for effective supplier inquiries.

First, clearly define the specific purpose, application scenarios, and core performance requirements of the wire harness. This includes:

- Application Environment: The equipment in which the wiring harness will be used and the operating environment.

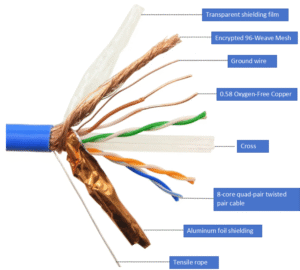

- Electrical Performance: Required voltage levels, current ratings, signal types, frequencies, and shielding requirements for electromagnetic interference.

- Mechanical Performance: Including total harness length, branch lengths, cable flexibility, abrasion resistance, tensile strength, and connector mating cycles.

- Specifications: Wire gauge, color coding, terminal and connector models, overall outer diameter, etc.

Translating the specific requirements for the aforementioned wiring harness into standardized technical documentation forms the foundation for accurately communicating needs with suppliers. At least one of the following materials should be provided: detailed engineering drawings, physical samples, or a comprehensive requirements specification.

JinHai will provide technical consultation and feasibility studies for your requirements. We help ensure the practicality of your solution and proactively identify potential design flaws.

Evaluating Wiring Harness Manufacturers

Selecting the right manufacturer is the most critical step in custom wiring harness procurement. Assessing a manufacturer’s professionalism requires evaluating their ability to provide expert technical support and whether their supply chain operates as a closed-loop system.

- Technical Capability Assessment:

- R&D and Design Capabilities: Does the manufacturer possess a robust technical R&D team and independent design capabilities?

- Production Processes and Equipment: Advanced processes and equipment ensure product quality.

- Customization Capabilities: JinHai manufacturers can rapidly respond to customer needs, support flexible orders for small batches and diverse varieties, and provide more cost-effective solutions to optimize costs or shorten lead times.

- Quality Management System Certifications: Verify whether the manufacturer has obtained key industry quality system certifications. Examples include ISO 9001, IATF 16949, IPC/WHMA-A-620, UL, CE, RoHS, etc., to measure product compliance.

- Comprehensive Evaluation of Overall Capabilities:

- Production Capacity: Assess factory scale, automation level, and production capacity through on-site visits or video reviews.

- Industry Experience: Review the manufacturer’s project experience and successful case studies with well-known enterprises.

- After-Sales Service: Clearly define after-sales service and technical support capabilities.

Understanding Budget Formulation and Cost Control

Budget formulation and cost control are essential safeguards for achieving cost-effective procurement.

Gaining a Deep Understanding of Custom Wire Harness Cost Structure

The price of custom wire harnesses is composed of multiple factors.

- Material Costs: The primary component of the cost structure. Includes:

- Conductors

- Insulation/Sheathing Materials

- Terminals and connectors

- Auxiliary materials: heat shrink tubing, cable ties, labels, shielding layers (copper foil, braided mesh), etc.

- Obsolete materials

- Processing and Labor Costs: Harness assembly remains a labor-intensive industry. Cost-influencing factors:

- Process complexity: Higher costs correlate with increased manufacturing steps.

- Automation level: Automated equipment can significantly reduce costs, particularly for high-volume orders.

- Development and tooling costs: Custom connectors, housings, or fasteners require investment in mold development.

- Testing and certification costs: Ensuring compliance with specific standards or customer-specific functional testing requires dedicated testing resources.

- Other expenses: Material wastage during production, packaging and shipping costs, plus the manufacturer’s reasonable profit margin and taxes.

The above factors constitute the cost structure of wire harnesses. Additional variables such as design complexity, procurement volume, delivery lead times, and commodity price fluctuations also influence final costs.

Budget Formulation Process and Methodology

Developing a realistic procurement budget requires integrating requirement specifications, market research, and cost analysis.

- Requirement Analysis and Preliminary Estimation: Conduct an initial cost assessment for the required wire harness based on project specifications and historical procurement data (if available).

- Market Research and Quotation Requests: Select 3-5 manufacturers passing the preliminary evaluation and issue formal requests for quotation (RFQs). Provide standardized, detailed technical documentation to ensure quotation accuracy.

- Cost Analysis and Budget Preparation: Upon receiving quotations, request manufacturers to provide itemized breakdowns. Analyze the reasonableness of material costs, processing costs, mold fees, etc.

- Dynamic Budget Adjustment: Develop a formal budget based on market conditions, subject to company review to ensure alignment with corporate strategy. Reserve 10-15% of the budget as contingency funds to address risks such as raw material price increases or design changes.

- Cost Calculation Model: Total Cost = (Σ Material BOM Cost / (1 – Scrap Rate)) + (Total Standard Labor Hours × Hourly Rate) + Development/Mold Costs + Overhead & Profit.

Risk Management for Buy Custom Wire Harness Orders

Strategies for Raw Material Price Fluctuations

The wire harness industry is significantly impacted by fluctuations in raw material prices like copper. Pre-establishing response mechanisms in contracts is critical.

- Price Indexation Agreement: Contractually stipulate that the final wire harness price is linked to a recognized raw material price index (e.g., LME copper monthly average). Establish a base price and fluctuation range; when raw material prices exceed this range, both parties adjust prices according to a predetermined formula.

- Long-Term Agreements & Price Locking: Enter into 6-month or 1-year long-term procurement agreements with manufacturers to lock in a fixed price or narrow fluctuation range, mitigating cost risks from short-term market volatility.

Contract Execution and Risk Management

Final procurement plans are formalized through rigorous contracts. Contracts serve not only as transaction documentation but also as risk management tools.

- Key Clause Review: Ensure the contract explicitly defines core terms including: detailed product specifications and technical standards, quality acceptance criteria, clear delivery dates and locations, packaging requirements, payment methods and cycles, mutual liability for breach, intellectual property ownership, and after-sales service and warranty periods.

- Written Confirmation: All verbal agreements and commitments must be clearly and unambiguously documented in the written contract.

JinHai’s Buy Custom Wire Harness Services

In custom wire harness procurement, JinHai is committed to growing alongside partners, empowering your products with enduring competitiveness.

- Building Long-Term Strategic Partnerships: Moving beyond transactional relationships, we view clients as strategic partners for sustained growth. Through efficient project communication and high-quality delivery, we build robust relationships based on mutual trust and shared success.

- Flexible Customization: We offer flexible customization services tailored to client needs, enabling on-demand production. This helps reduce finished goods inventory, lower capital tied up in stock, and respond more quickly to market changes.

- Full-Process Quality Control: We integrate quality control throughout every stage of production—from design and material selection to manufacturing, testing, and final delivery.