Customized Wiring Harnesses

Wire harnesses serve as rapid, efficient, and stable conduits for signal and power transmission within electrical systems, with industries across the board demanding highly customized solutions. Their modular assembly and flexible, customizable design enable adaptation to complex layouts, while high protection ratings deliver outstanding interference resistance and environmental durability. Consequently, they find extensive application in automotive, industrial, agricultural machinery, and household appliance sectors.

China Customized Wire Harnesses Manufacturer

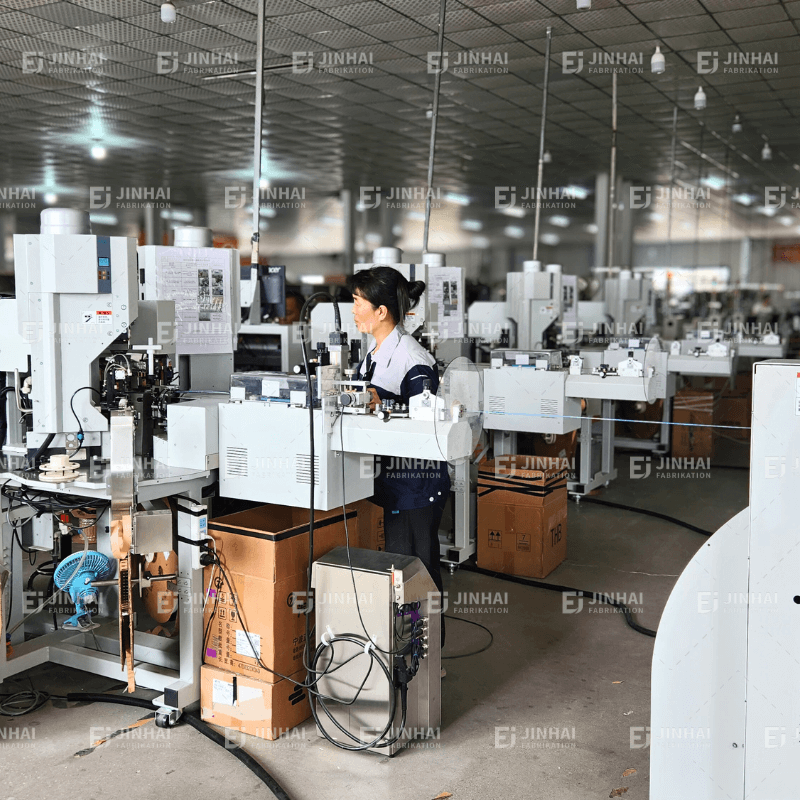

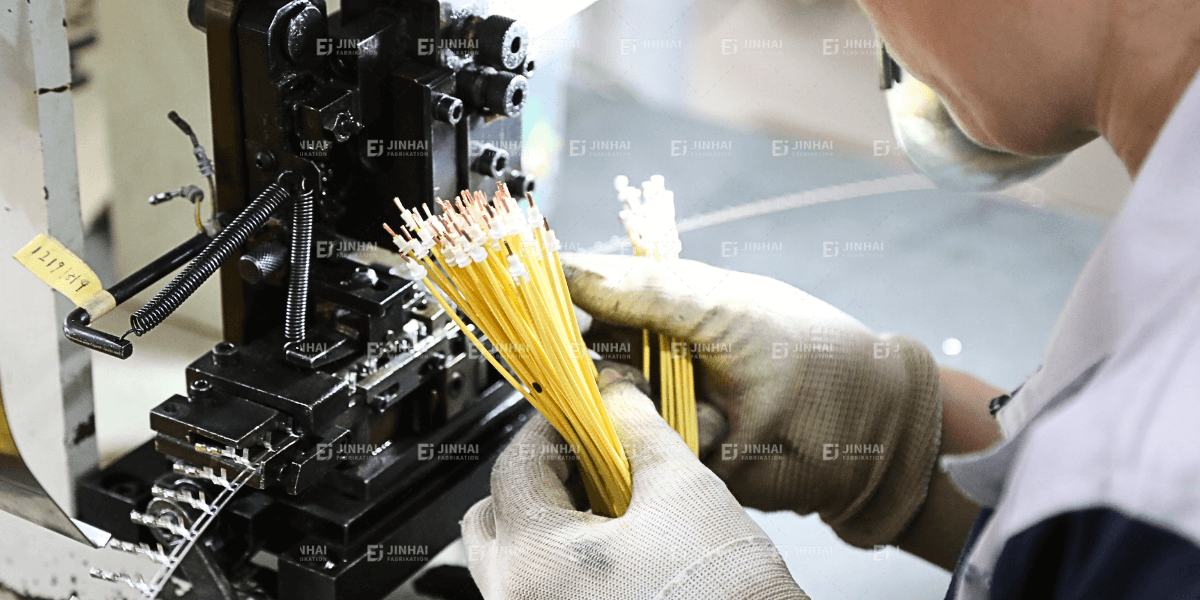

As a critical component of vehicles, wiring harnesses ensure the stable transmission of electrical power and signals. Their reliability directly impacts the overall performance of the vehicle. Through automated crimping and assembly, wiring harnesses connect various sub-components to form safe and dependable electrical systems. This enables us to provide products that comply with local laws and regulations for customers worldwide.

At JinHai, drawing on years of experience supporting international brands, we have mastered high-precision machining, automated production, and modular design technologies to meet complex wiring harness layouts. Furthermore, our localized supply chain and large-scale production reduce costs, and our flexible production scheduling allows for rapid response to customized needs, shortening lead times and improving customer satisfaction.

Automotive Wiring Harnesses

Automotive Air Conditioning Wiring Harness

Automotive Seat Wiring Harness

Automotive Door Wiring Harness

Automotive Engine Wiring Harness

Automotive Instrument Wiring Harness

Automotive Chassis Wiring Harness

Automotive Roof Wiring Harness

Motorcycle Wiring Harness

Customized Wiring Harness

Performance Wiring Harness

E-Motorcycle Wiring Harness

Touring Motorcycle Wiring Harness

Agricultural Machinery Wiring Harness

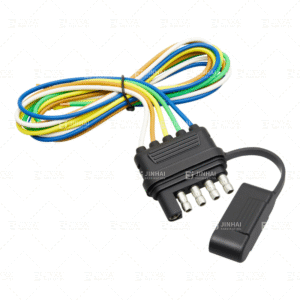

Trailer Wiring Harness

Power Cable Harness

Agricultural Sensor Wiring Harness

Agriculture Lighting Wiring Harness

Home Wiring Harnesses

AV Wiring Harness

IoT Communication Harness

Frequency control harness

IP68 Waterproof Power Cable Harness

Advantages of JinHai Customized Wiring Harnesses

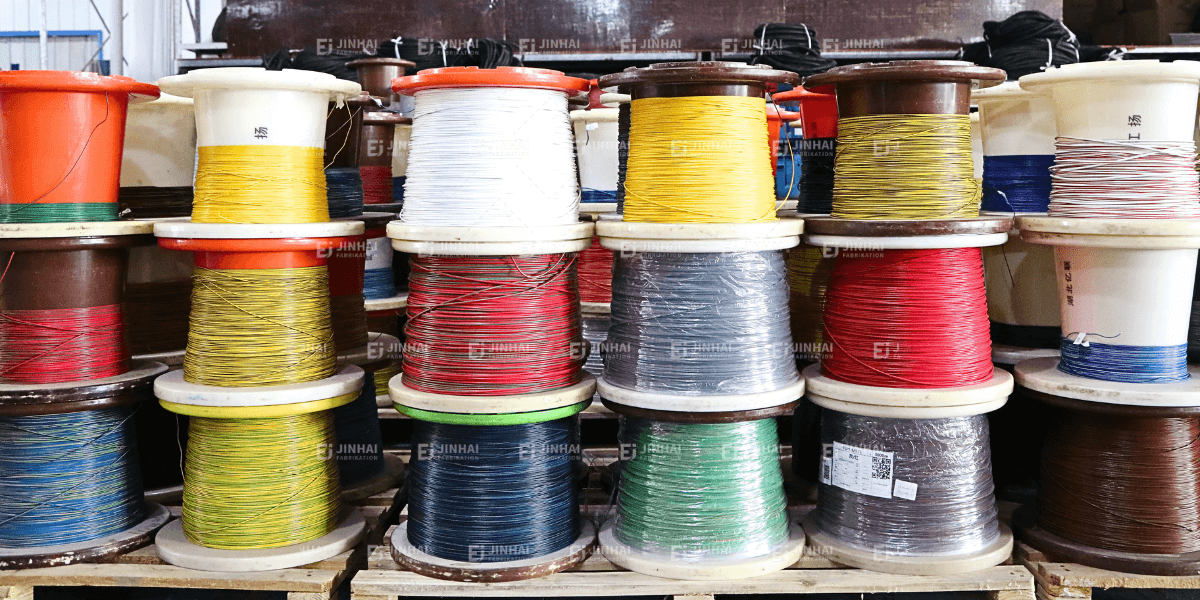

Cost Advantage: JinHai wiring harness products benefit from a complete industrial chain and large-scale production capacity. Lower raw material procurement costs (e.g., copper, PVC) combined with labor costs more competitive than developed countries result in overall cost competitiveness for finished wiring harnesses.

Delivery Advantage: China stands as the global manufacturing hub, boasting stronger production capabilities than ever before. Our highly centralized supply chain and rapid response times grant JinHai products a robust delivery advantage, enabling us to fulfill urgent customer orders.

Technical Advantage: hrough years of development, JinHai Wiring Harnesses has accumulated valuable experience across automotive, consumer electronics, smart home, motorcycle, and agricultural machinery sectors. Our automated production equipment (including fully automatic crimping machines and contour inspection systems) undergoes continuous upgrades, while manufacturing techniques are constantly refined. Current process precision reaches ±0.1mm, with product consistency surpassing some emerging markets.

Customization Capabilities and Policy Advantages: JinHai possesses flexible adaptability to meet diverse national standards. We rapidly design solutions tailored to client requirements, including high-temperature resistance (above 150°C) and waterproofing (IP67). Concurrently, to enhance international competitiveness, the government has consolidated trade product supply chains and established multiple ports in coastal cities to accommodate growing trade demands.

Applications of JinHai Custom Wire Harnesses

JinHai wire harnesses demonstrate strong competitiveness across automotive, motorcycle, agricultural, industrial, smart home, and new energy sectors.

From engine compartment harnesses to complete vehicle harnesses, door panel harnesses, seat harnesses, and seat assembly harnesses, our solutions deliver exceptional efficiency, high quality, and cost-effectiveness for your enterprise. JinHai wire harnesses play a critical role in automotive, motorcycle, and smart home applications.

In agriculture, JinHai wiring harnesses deliver stable power and signal output for your agricultural machinery, ensuring continuous operation unaffected by environmental factors.

In short, JinHai wiring harnesses reduce procurement costs and boost corporate profits while guaranteeing high quality and rapid delivery.

China's Leading Wire Harness Manufacturing Factory

- Precision Cutting and Crimping: Precision cutting and automated crimping ensure stable, reliable connections between wire harness sub-components (wires, terminals), thereby enhancing electrical performance and assembly efficiency.

- Premium Material Selection: Choose from specialized materials like PVC, XLPE, TPE, corrugated tubing, and tape based on your specific application environment (high-temperature resistance, oil resistance, abrasion resistance) or OEM specifications to guarantee harness reliability and durability.

- Customized Jackets and Labels: Flexible color customization options for wire harness jackets, tapes, or labels allow you to tailor the harness appearance according to brand specifications (e.g., OEM color coding) or functional differentiation needs, enhancing identification and aesthetics.

- Strict Industry Compliance and Quality Assurance: Our harness manufacturing processes strictly adhere to core automotive industry management systems (e.g., ISO9001 / IATF 16949, IPC/WHMA-A-620), meet OEM-specific requirements, and ensure product reliability, safety, mechanical protection, and environmental adaptability.

What types of connectors does JinHai offer?

JinHai’s most competitive areas:

- Automotive connectors (terminal connectors like JST, TE, MOLEX, etc.; high-voltage connectors; high-speed data connectors; RF connectors)

- Consumer electronics connectors (board-to-board connectors; wire-to-board connectors; FPC/FFC connectors; I/O connectors; battery connectors)

- Industrial connectors (circular connectors M series, rectangular connectors Harting Han series, aviation connectors, and terminal blocks)

- Communication and data center connectors (RJ45 connectors, fiber optic connectors, and backplane connectors)

- Medical device connectors (LEMO circular connectors and various custom connectors)

Can samples be provided before mass production?

Certainly. JinHai can provide you with 1-5 samples.

Is there a charge for samples?JinHai offers two options for your consideration.

- Simple, low-value samples: If you clearly express your intention to collaborate with Jinhai (typically requiring detailed drawings, specific quantity requirements, and a delivery schedule), we will charge 60%-80% of the standard sample price. We commit to deducting this sample fee from the order payment when subsequent bulk orders are placed.

- Complex, high-value samples: For products involving hundreds of circuits, specialized connectors, or expensive shielding layers, we charge standard sample fees. However, we commit to refunding the sample cost if your subsequent order exceeds 10 times the sample value.

Sample Lead Time

- Upon receiving your sample request, JinHai will complete sample production within 1-3 weeks and ship it to your location via international express delivery.

How to Protect Wiring Harnesses During Transportation?

- Moisture Prevention Measures: At JinHai, wiring harnesses are packaged in cardboard boxes.

- Internal Moisture Protection: Two methods are used—PE bags or aluminum foil bags (specific method determined by customer specification or provision)—with three desiccant packets per box for additional moisture control.

- External Moisture Protection: After final packaging, products are placed on pallets for shipment. Prior to dispatch, goods on pallets receive secondary protection with stretch wrap.

- Shock Absorption Solutions:During transit, wiring harnesses experience vibrations and jostling. To prevent damage to critical connectors, JinHai offers enhanced shock absorption solutions:

- Wrapping entire harnesses in bubble wrap for protection;

- Using custom-shaped EVA foam to wrap harnesses or as padding/separators;

- Employ custom-molded foam liners specifically designed for high-value wiring harnesses.

All packaging methods listed above are provided by JinHai. Should customers specify alternative packaging requirements, we will strictly adhere to those instructions.