Custom Molex Cable Assembly Manufacturer

As a premier manufacturer of MOLEX cable assemblies, we specialize in providing sealed enclosures and high-density data transmission solutions.

These cable assemblies outperform generic components and can be customized with pin definitions, special lengths, specialized operating environments, and unique materials.

Our Clients

JinHai, as a leading manufacturer of medical cable assemblies, specializes in producing medical-grade cable assemblies tailored for the healthcare industry.

Our strength lies in designing medical cable assemblies that meet your specific requirements and satisfy OEM manufacturers.

What can we do for your Molex cable assemblies ?

Project Requirements:

- Wiring harness operating environment (extreme temperatures, dustproof or waterproof environments, etc.)

- Performance requirements (current-carrying capacity, flexibility, data transmission speed)

- Industry-specific certifications (automotive, military, medical)

- Layout requirements (space constraints, minimum bend radius)

Prototype Design and Manufacturing:

Our engineers will use CAD drawing tools to create a 3D digital model for you, considering the following factors during design:

- Connector type: waterproofing, gender, locking type (integrated TPA or built-in TPA), number of PIN pins.

- Wire Specifications: Stranding method, wire gauge, compatibility with terminals.

- Shielding Layer: Single-layer aluminum foil, metal braid layer, or hybrid layer.

- Branch Design: Branch routing, mounting method.

Before mass production, you will receive a prototype sample for testing or assembly evaluation.

Precision Craftsmanship:

Our engineers rigorously validate each process step:

- IPC-compliant crimping or soldering techniques

- Custom overmolding tailored for environmental adaptability

- Strict 100% self-inspection and cross-inspection at every stage

- All components meet traceability requirements under the TS16949 management system.

Quality Management and Testing :

All products undergo the following tests in accordance with quality management requirements prior to delivery:

- Connectivity: 100% verification of proper plugging and connection.

- Signal Integrity: Verified to achieve high-speed transmission performance.

- High-Voltage Testing: Ensures complete insulation integrity.

- Mechanical Testing: Tensile strength and bending endurance.

- Environmental Testing: Temperature cycling and humidity tolerance.

Delivery and After-Sales Support :

We can provide:

- Delivery documentation: Raw material certification, product shipment reports

- Packaging options: Customizable knife cards, dividers, electrostatic protection, and moisture/dust-proof protection

Inventory management for recurring orders

Support for engineering and technical iterations

Our Products

We can integrate MOLEX premium connectors into a variety of custom wire harness solutions.

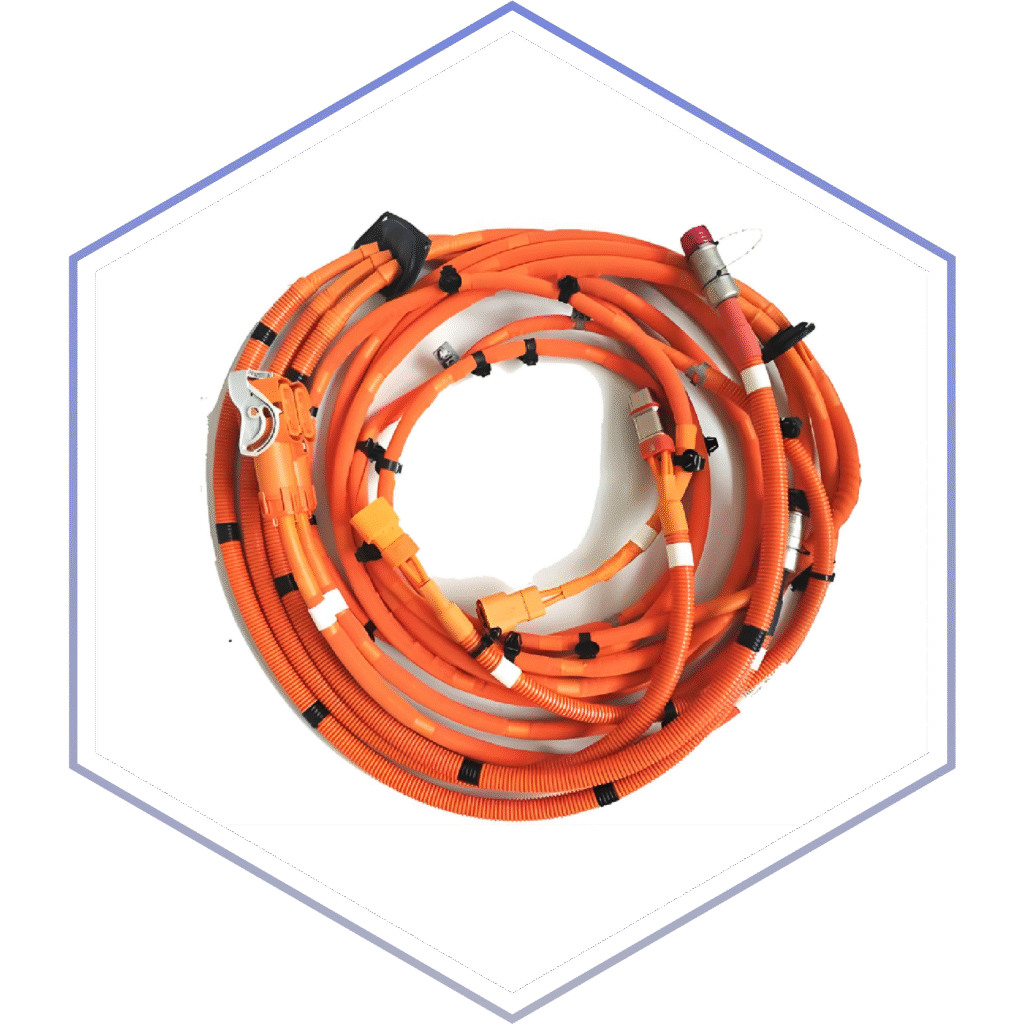

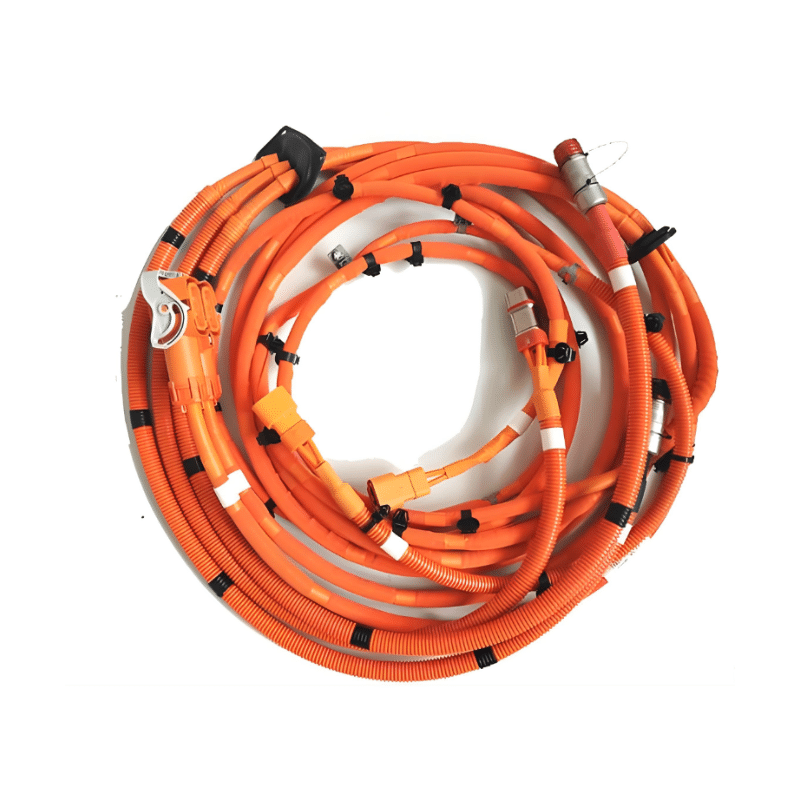

High-voltage wiring harness cable assemblies

Capable of withstanding voltages exceeding 1000V and currents exceeding 300A, it serves as a specialized component for new energy vehicles or construction equipment.

Sealed Cable Assembly

IP67-rated connectors provide triple protection against water, dust, and solid ingress, making them suitable for harsh environments such as agriculture, marine applications, and outdoor settings.

Independent Shielded Cable Assembly

The independent shielding design effectively blocks interference between cable assemblies, making it the ideal choice for medical and aerospace equipment.

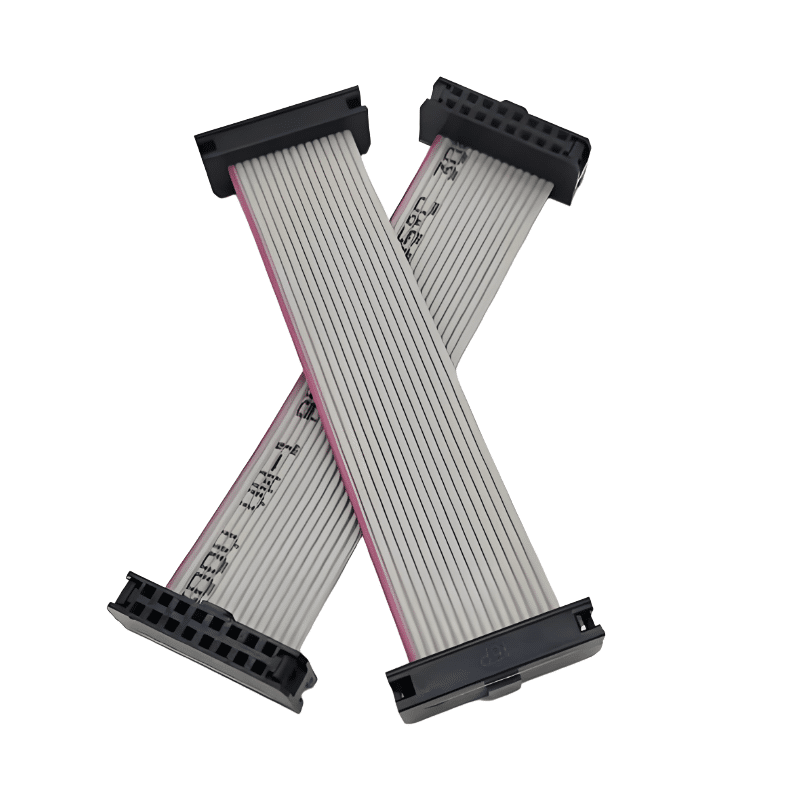

Flat Cable Assemblies

Ultra-thin pitch solutions for such cables are better suited for devices with limited space constraints, such as robots and drones.

Overmolded Cable Assemblies

The molded stress-relief feature combined with a high waterproof rating makes this cable exceptionally durable, making it ideal for outdoor use.

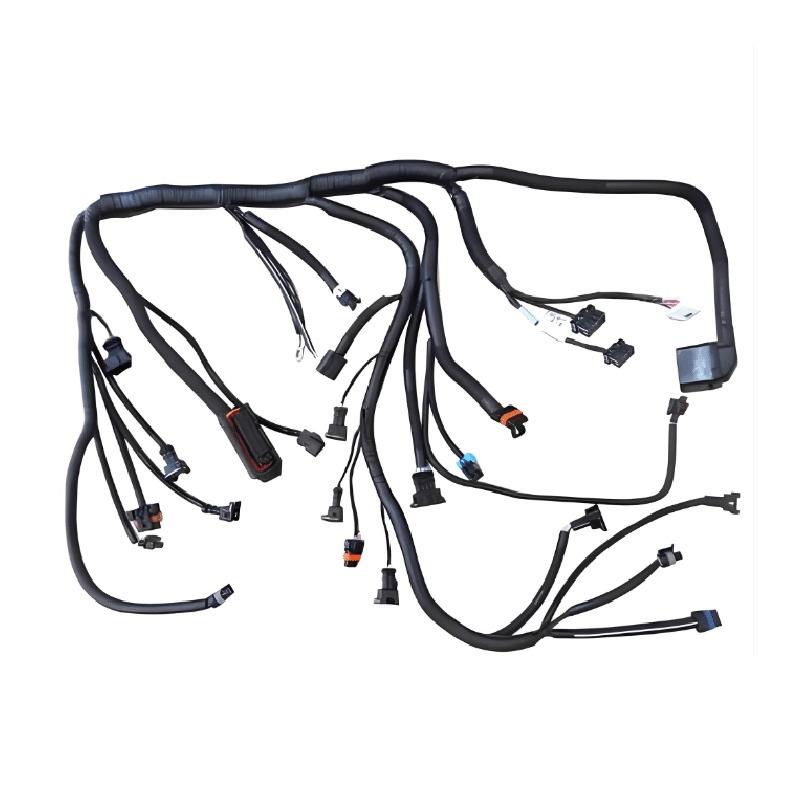

Medical Device Power Cord

Custom wiring harnesses with labeled cables for quick and error-free installation in vehicles and machinery.

Molex Connector Types

JinHai will select the appropriate connector solution based on your performance requirements and environmental conditions.

Mini-Fit Max Connector

The wire-to-board connector features a compact package delivering 20.5 A current, with a robust handle-free terminal design and TPA-enabled sockets offering 2 to 12 positions. Manufactured from low-cost, safety-certified materials, it meets European electrical standards while ensuring terminal security during assembly. TPA detents help secure terminals firmly within the housing, minimizing the risk of terminal fallback.

Brad Series Connectors

Brad Industrial Communication and Connectivity Automation Solutions are rugged industrial infrastructure solutions designed for harsh manufacturing environments, such as automotive, food and beverage, material handling, and commercial vehicle sectors.

Squba Sealed Wire-to-Wire Connector

The 3.6 mm and 1.8 mm pitch sealed wire-to-wire connector system is designed for space-constrained applications. UL-certified and IP68-rated, it supports currents up to 14A, delivering stable power output in compact spaces.

FFC/FPC Connectors

FFC and FPC connectors offer multiple options with pitch sizes ranging from 0.20 mm to 2.00 mm and circuit sizes from 2 to 120. These connectors are designed to provide reliable, durable solutions that enhance flexibility in use.

Extreme PowerEdge Plus Card Edge Connector

Its compact and ultra-thin design enables high current density. This connector delivers lower contact resistance, reduced power loss, and enhanced reliability. While meeting M-CRPS mechanical requirements, it exceeds electrical specifications, providing additional performance headroom for future updates and iterations.

MMCX Coaxial Power Over Coax (PoC) Connector

This connector employs a fully locking connection mechanism. The solution is specifically designed for frequencies up to 6GHz. It ensures full compatibility with MMCX receptacle connectors and provides stable, reliable ground continuity.

Application field

Molex cable assemblies are used in the following industries:

Automobile

Advanced driver assistance systems for Level 3 autonomy, new energy battery pack wiring harness assemblies, and various powertrain wiring harnesses, capable of withstanding high temperatures, vibration, and humid environments.

Healthcare sector

Suitable for mobile emergency medical equipment and monitoring devices.

Industrial

Compact, high-efficiency solutions for robots, drones, and various smart home devices.

Why Choose JinHai ?

We are committed to delivering fully customized connectivity solutions while ensuring comprehensive quality assurance.

Customization Beyond Expectations

From custom pin configurations to standard-compliant shielding options, we tailor Molex connectors and cables to your specific requirements.

Precision Crafted

Through precise process control, we ensure every product meets tolerance specifications and passes 100% connectivity and signal integrity testing.

Full-process support

We provide one-on-one end-to-end service support to ensure your needs are met from design through after-sales service.

Reliable supply-demand relationship

Our long-term, stable strategic partnerships with suppliers enable us to handle any situation, ensuring consistent quality and on-time delivery even during raw material shortages.

Quality and Safety, Guaranteed

Adhering to IPC/WHMA-A-620 standards, we ensure reliability and performance in each product.

For wire harness assemblies, besides Molex connectors, what other brands can I choose?

If you prefer not to use Molex connectors, we can also provide connectors from brands such as SATA, PCIe, and EPS.

What are the applications of Molex components?

Some Molex connectors are used to supply power to motherboards, fans, floppy disk drives, CD/DVD drives, graphics cards, and some older hard disk drives.

What is the minimum order quantity for Molex components?

We offer tiered pricing for small-batch orders based on shipping rates, with varying discounts at each tier. For details, please contact JinHai for consultation.