Professional Custom Automotive Wire Manufacturer

JinHai is a TF16949-certified automotive wiring harness manufacturer. We provide customized wiring harness manufacturing for all vehicle positions, ensuring exceptional quality, reliability, and optimal performance.

Our Amazing Clients

JinHai is a premier automotive wiring harness manufacturer specializing in providing high-quality customized solutions for electric, gasoline, and hybrid vehicles.

Our exceptional craftsmanship ensures safe, durable, and high-quality wiring harnesses that meet IATF 16949 requirements. Our sales and design teams maintain close collaboration with customers throughout the entire process to meet their needs.

Why Choose JinHai ?

JinHai is the preferred wire harness manufacturer for numerous automotive companies for the following reasons:

Fast Shipping

We can deliver bulk orders within 2 to 6 weeks, but the exact delivery time may vary depending on the order size and product complexity.

High-Quality

JinHai provides premium products that undergo rigorous manufacturing controls and testing to meet industry standards.

Professional

The wiring harnesses we provide are designed to meet your requirements. They include: engine, chassis, door panels, seats, and instrumentation.

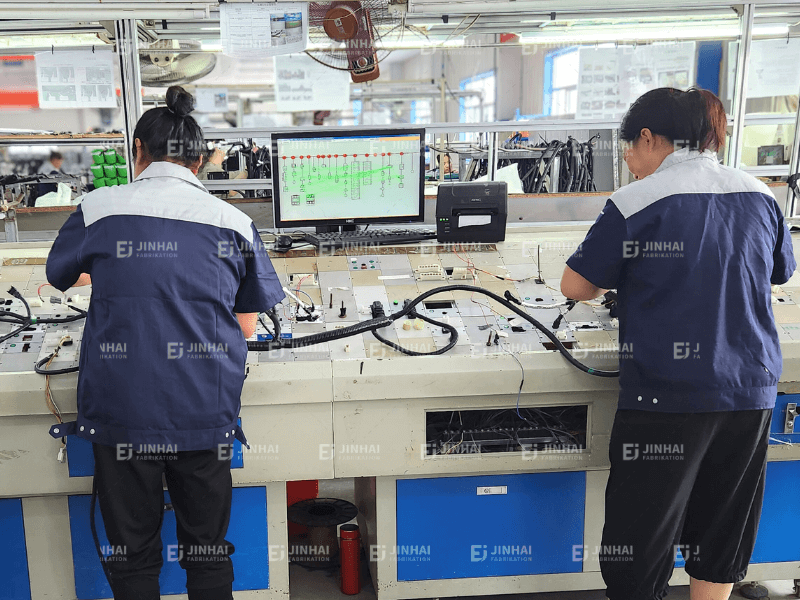

Professional Equipment

JinHai possesses multiple state-of-the-art fully automated crimping machines. This transition from manual manufacturing and inspection to automated production and quality assessment has elevated our process automation levels while reducing risks associated with manual operations.

One-on-One Service

We provide one-on-one service throughout the entire process from design to production.

Diverse Options

JinHai manufactures wiring harnesses based on your designs, offering maximum flexibility with alternative solutions for new energy vehicles, natural gas vehicles, hybrid vehicles, gasoline vehicles, and more.

Service Offerings

We provide comprehensive solutions with customized support. This includes:

- Wire cutting

- Stripping

- Crimping

- Soldering

- Termination.

Wire harness assembly

Precision machining, including 0.1-millimeter-level length tolerances, specialized bending angles, and non-standard terminal crimping.

Value-added services include

8-hour quote response, custom wire gauge, product appearance and functionality testing, and production support for multiple types.

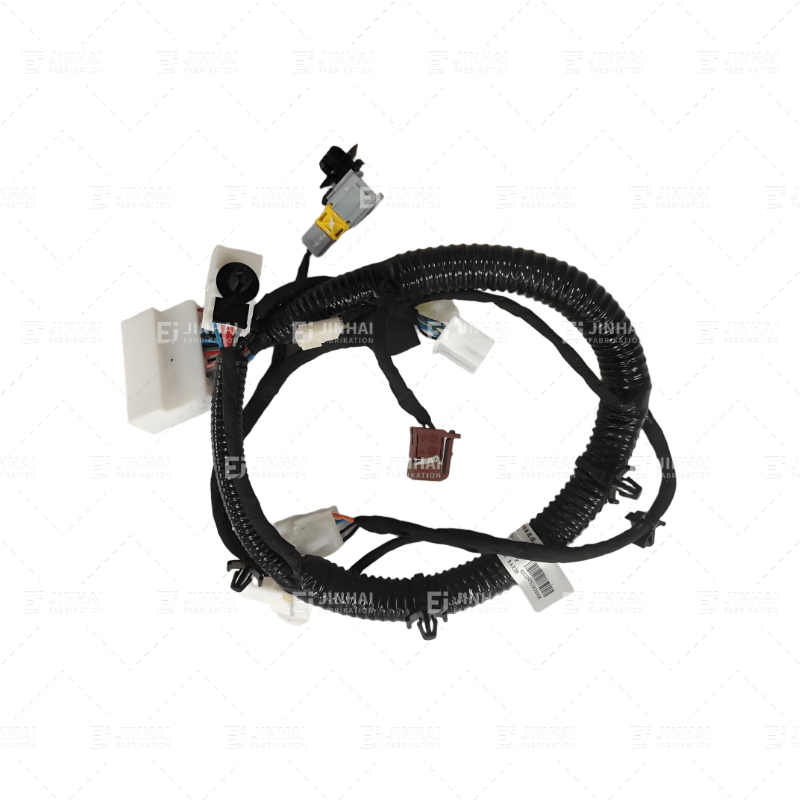

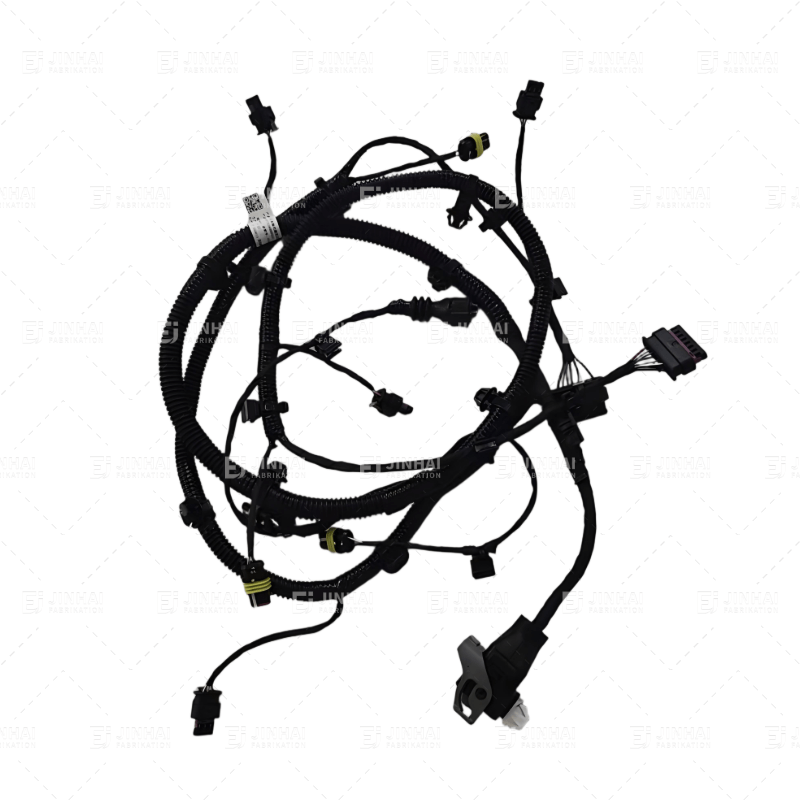

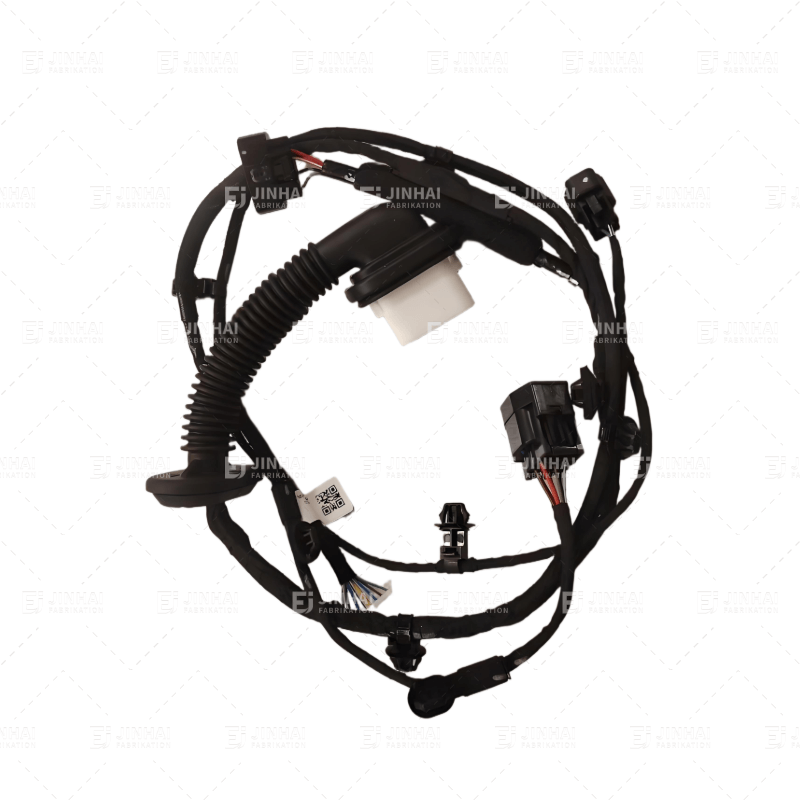

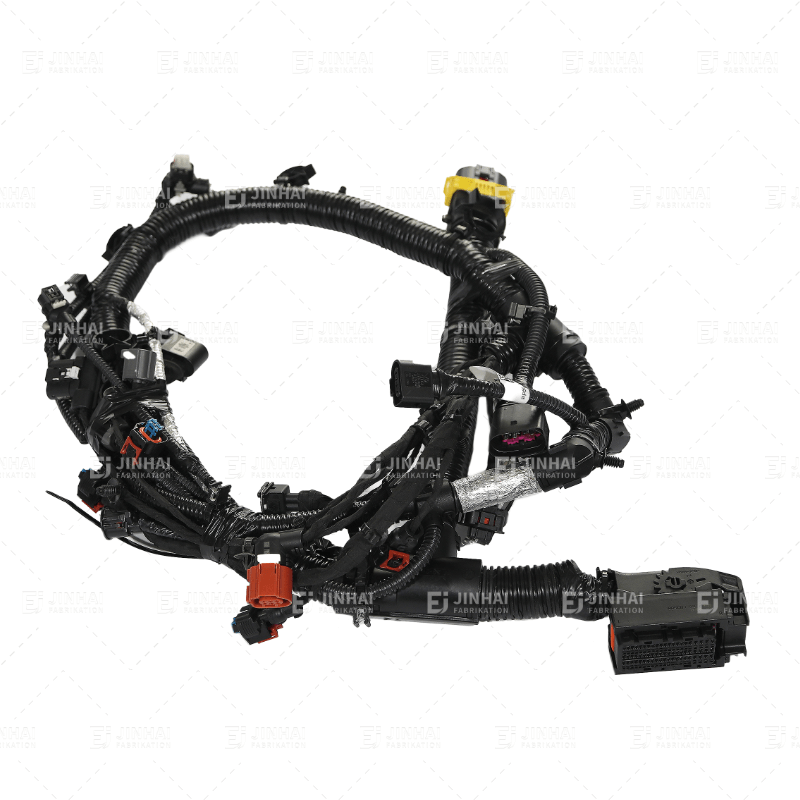

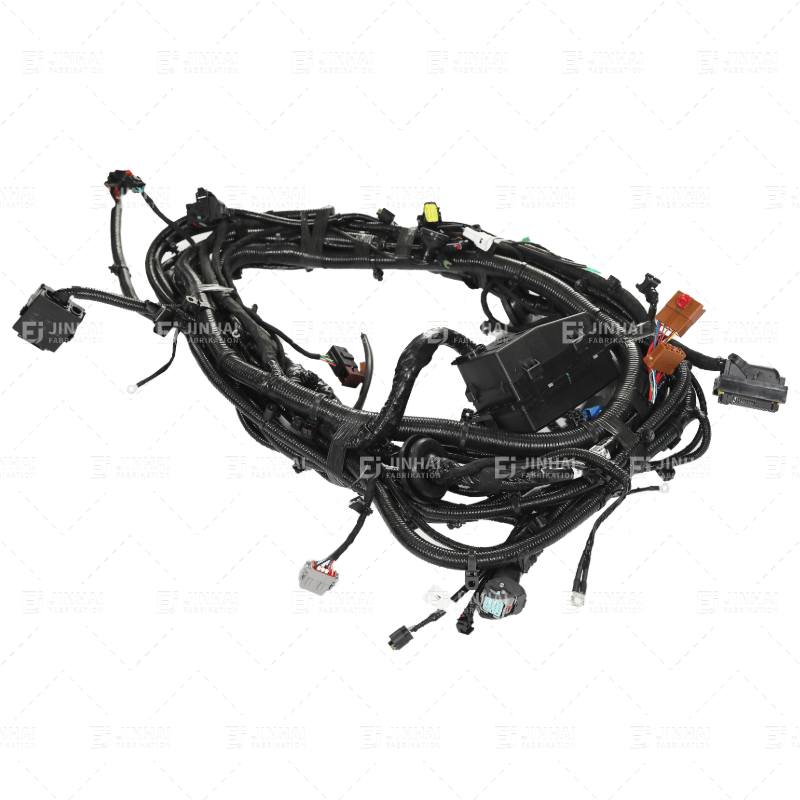

JinHai Custom Automotive Wiring Harness

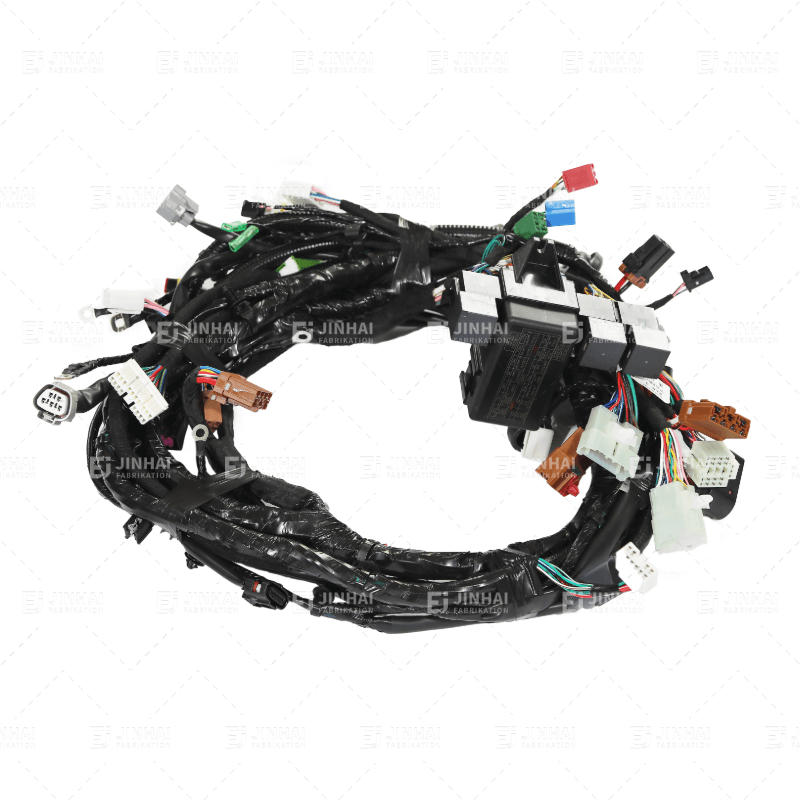

As a professional automotive wiring harness manufacturer in China, we provide manufacturing services for engine harnesses, instrument panel harnesses, chassis harnesses, roof harnesses, door harnesses, seat harnesses, air conditioning harnesses, and more.

JinHai China: Your one-stop OEM/ODM automotive wiring harness manufacturer. We have the capability to address your product requirements—from design drawings to mass production.

- Multiple fully automated precision equipment

- ISO standard compliance

- Rapid response with quotes within 48 hours

- Quick prototyping

- Flexible small-batch production and large-scale supply

JinHai possesses professional wire harness customization capabilities. We provide comprehensive solutions encompassing functionality, materials, and application environments.

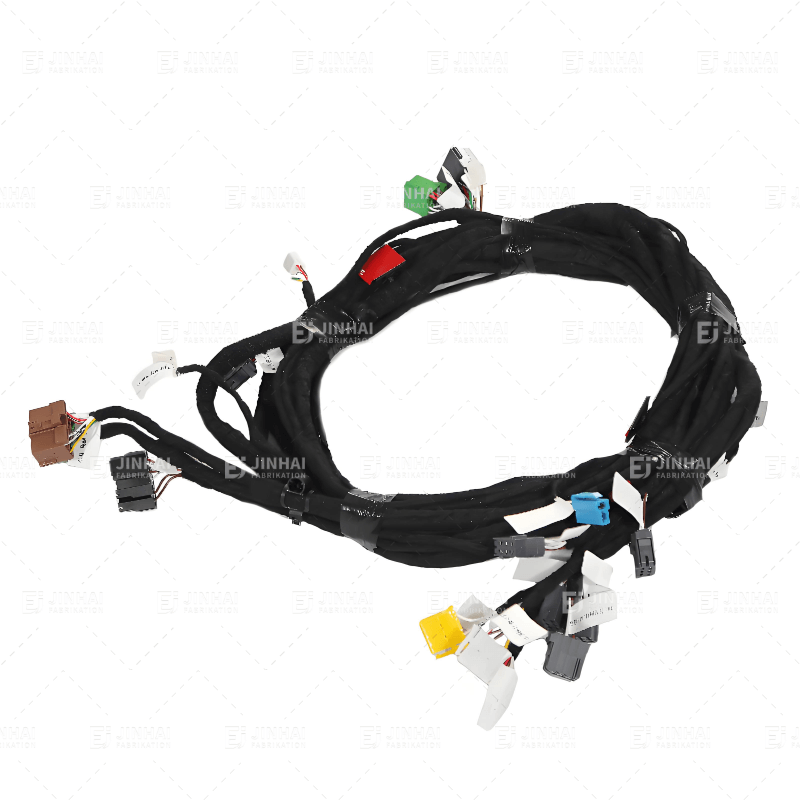

- High-temperature environments: Select heat-resistant materials such as silicone rubber or specially formulated cross-linked polyolefin.

- Chemically corrosive environments: Choose materials with superior acid and alkali resistance, such as PTFE or specially formulated EPDM rubber.

- Marine environments: Materials must exhibit superior salt spray resistance and waterproofing, with consideration for mold growth prevention.

- High-frequency electromagnetic signal environments: Employ composite sheath structures with metal braiding layers to ensure signal integrity while preventing external interference.

- Mechanical protection design for sheaths varies based on specific application scenarios, such as:

- Crush-exposed harnesses (e.g., vehicle chassis wiring): Sheaths must possess sufficient compressive strength;

- Outdoor-exposed harnesses: Sheaths require UV resistance;

- Vibration environments (e.g., agricultural machinery): Sheath materials should exhibit fatigue resistance and be adapted to harness mounting methods.

- Moderate sheath wall thickness provides adequate protection while minimizing costs.

We are confident in meeting your requirements for product functionality, quality, and budget.

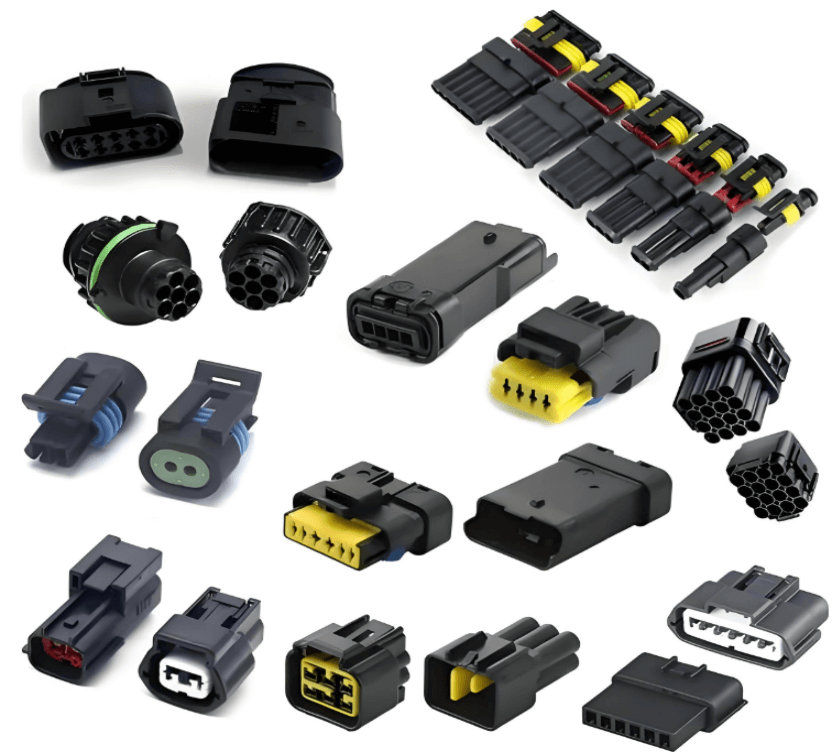

Connectors serve critical functions in physical protection and environmental sealing, with material selection tailored to specific application requirements. Common connector materials include:

- PVC

- Thermoplastic Elastomer

- Chloroprene Rubber

- Polyurethane

- Passenger vehicles, commercial vehicles, and new energy vehicles

- Industrial equipment manufacturing, automotive manufacturing, and machinery

- Heavy-duty trucks and construction machinery

JinHai automotive wiring harnesses serve a wide range of applications. We can provide wiring harnesses tailored to your diverse requirements.

We deliver solutions that perfectly align with your needs and budget.

JinHai manufacturers offer you a wide selection of materials and manufacturing processes. Based on your project requirements, our services include:

- Product Communication: At the outset of your project, JinHai will engage in detailed discussions with you to understand your requirements regarding drawing specifications, materials, and application scenarios. We will provide professional design recommendations and solutions when necessary.

- Material Selection: Based on the application environment, JinHai will recommend suitable materials to ensure the durability and functionality of your wiring harness.

- Free Quotation: After confirming your harness requirements, we will provide a quote based on your specified quantity. If you need shipping cost estimates, we will promptly verify them to help you fully evaluate project costs.

- Sample Production and Testing: Samples are rapidly produced by our professional manufacturing team. You may conduct comprehensive testing on our samples.

- Production of Formal Orders: Whether you require small or large batches, JinHai will proactively fulfill your order needs and deliver on time.

- Quality Inspection: JinHai implements strict quality control throughout all production processes.

- Shipping: JinHai provides logistics services. Your products will be delivered safely and promptly to the designated location. We offer ongoing after-sales service.

We are a professional automotive wiring harness manufacturer in China, dedicated to providing high-quality custom solutions. We warmly welcome you to source automotive wiring harnesses from our factory at highly competitive prices.

What causes damage to engine wiring harnesses?

The insulation, connectors, and fasteners in wiring harnesses can age and become brittle, making them prone to damage. Water immersion, high temperatures, physical wear, and rodent damage can also harm wiring—and such damage may not become apparent until a malfunction occurs or the wiring is moved.

What is the most common cause of automotive electrical problems?

Dead or low battery

A dead battery ranks among the most common automotive electrical issues and is also one of the most frustrating problems. Common signs: If your battery is about to die or is low on charge, you may notice: difficulty starting the vehicle or dim interior lights.

How much does it cost to replace a wiring harness?

How much does it cost to replace a wiring harness? A new wiring harness typically costs between $100 and $350. Labor charges can range from $800 to $1,500, depending on your vehicle’s make and model, as well as local rates in your area.

How to check the continuity of a wiring harness?

The simplest method is to use a multimeter. Connect the same-colored wires at both ends of the harness using the multimeter’s positive and negative probes. If a beep sounds and a reading appears, it indicates the wire is conductive. Otherwise, a fault is present.

What does a custom automotive wiring harness assembly include?

Custom wire harness assemblies include wires, connectors, terminals, protective materials, clips, and labels—tailored to your application requirements.

Do you provide sample production before bulk orders?

Yes. We support the production of prototype samples prior to mass production and ensure that prototypes undergo testing and adaptation before initiating mass production.

What types of vehicles are supported?

We offer a wide range of vehicles, including electric vehicles, gasoline-powered vehicles, hybrid vehicles, SUVs, motorcycles, and specialty vehicles.

Connector Type

TE, Delphi, THB, Molex, JST, JAE, or according to your requirements.

Certification

JinHai possesses over 20 years of experience and holds IATF 16949 and ISO 9001 certifications. This ensures every wire harness we produce meets the highest standards of quality and compliance.