Wiring Harness Quality

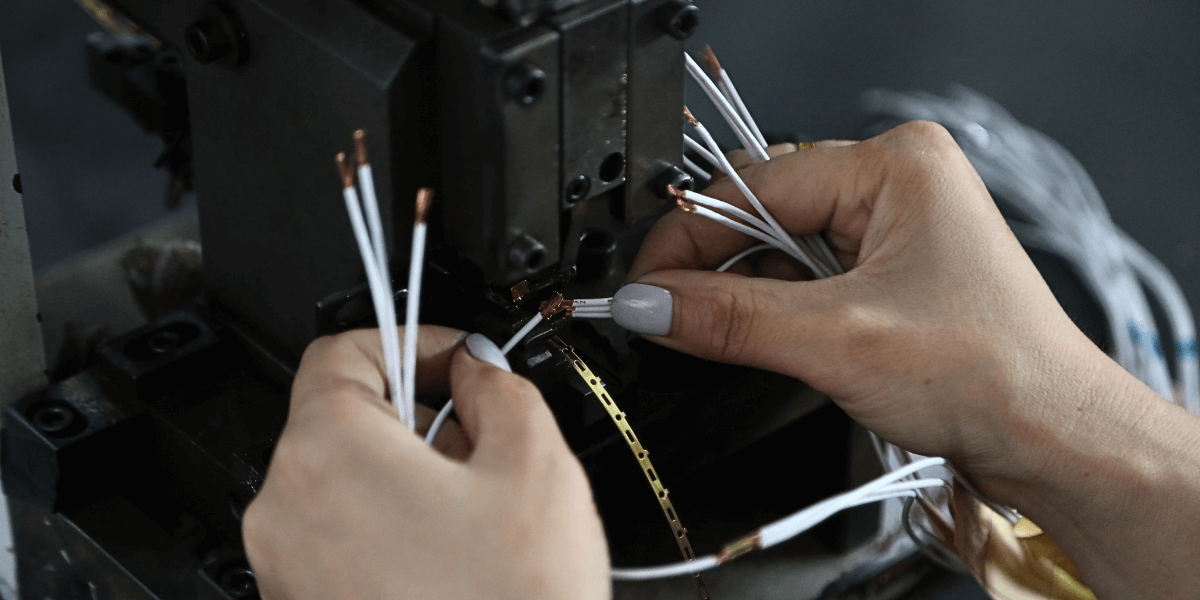

This is a quality control process during the wiring harness assembly process, so I simply ensure that the branch and cable tie dimensions for each harness are correct. Based on the drawings, JinHai has six inspectors: one for incoming material inspection, three internal inspectors for production steps, and two inspectors for the final product. All incoming raw materials, including terminals, connectors, and wires, are inspected according to international standards of AQL 6.5. Every step, including plugging, cable tie attachment, and branch attachment, is thoroughly inspected. The dimensions of each harness are 100% checked. Monthly quality review meetings are also held to identify issues and develop plans, using tools like 8D reports, PDCA, and FEMA.