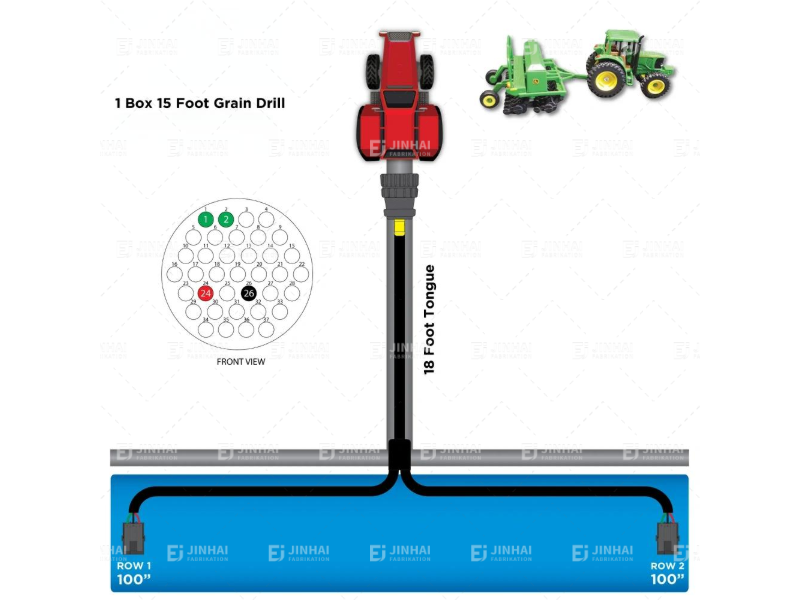

JinHai provides customized wiring harness solutions for agricultural machinery, ensuring precise compatibility with equipment models and sensor interfaces. Utilizing premium protective materials and stringent quality control during production, our wiring harnesses deliver outstanding high-temperature resistance, vibration resistance, corrosion resistance, and interference immunity, providing equipment with a stable electrical system.

JinHai’s agricultural machinery sensor harnesses are specially engineered to withstand harsh field conditions, including intense vibration, oil contamination, dust, and fluctuating temperature and humidity. Utilizing high-protection-rated cables and connectors combined with advanced shielding technology, JinHai ensures stable sensor signals and robust interference resistance.

Through precision customization, JinHai adapts to diverse agricultural machinery models and sensors, providing stable data connectivity for farm equipment. This significantly enhances the efficiency and reliability of agricultural machinery operations.

Contact us immediately to learn how we can meet your cable and harness requirements. Follow us on Youtube .

Our purchasing department uses a global strategy to source quality components from special channels.

Adhering to IPC/WHMA-A-620 standards, we ensure reliability and performance in each product.

JinHai designs wiring harnesses specifically for the harsh operating conditions of agricultural machinery. Leading the market with outstanding advantages.

Core Advantages:

1. Significantly lower failure rates than comparable products, ensuring operational continuity;

2. Features lossless adaptation technology for compatibility with mainstream devices, offering plug-and-play functionality.

3. Outstanding overall cost advantages, providing a more reliable, economical, and worry-free choice compared to other commercial solutions.

JinHai’s agricultural machinery sensor wiring harnesses have a wide range of applications, primarily including the following:

Power and Emissions: Monitor engines and aftertreatment systems to ensure efficient operation and compliance with emissions regulations.

Operation Control: Precision seeding, fertilizing, spraying, and harvesting enable variable-speed operations and optimize yields and resources.

Intelligent Driving: Supports GNSS navigation, obstacle sensing, and autonomous driving.

Safety Monitoring: Ensures braking, steering, operator safety, and critical system status.

How to handle quality issues or returns?

At JinHai, if there are any quality issues with the goods we ship, we generally handle them in the following three ways:

If the product cannot be repaired, JinHai will directly send the customer a good product to replace the defective one;

If the product is repairable, JinHai will negotiate with the customer and coordinate with a third party approved by the customer to assist with the repair, and the cost will be borne by JinHai;

Under normal order conditions, JinHai will give customers products at a rate of 0.1% of the order amount for later product maintenance or replacement.

Quality begins with details, and service builds trust. The Jinhai after-sales team is dedicated to resolving your issue!

If you need to custom wiring harness for your product, JinHai is your first choice. Send us your detailed requirement and get an instant quote now.

Room 1626, 4th Floor, Building 13, Xiuyuan, Dachengli, Fengtai District, Beijing, China