Who Are we?

JinHai is a manufacturer specializing in the R&D and production of wiring harnesses. The company engages in manufacturing for automotive, motorcycle, agricultural machinery, smart home wiring harnesses, and automotive central control switches. Products include engine compartment wiring harnesses, body wiring harnesses, seat wiring harnesses, door panel wiring harnesses, roof wiring harnesses, and automotive switches. We provide ODM/OEM services to domestic and international enterprises.

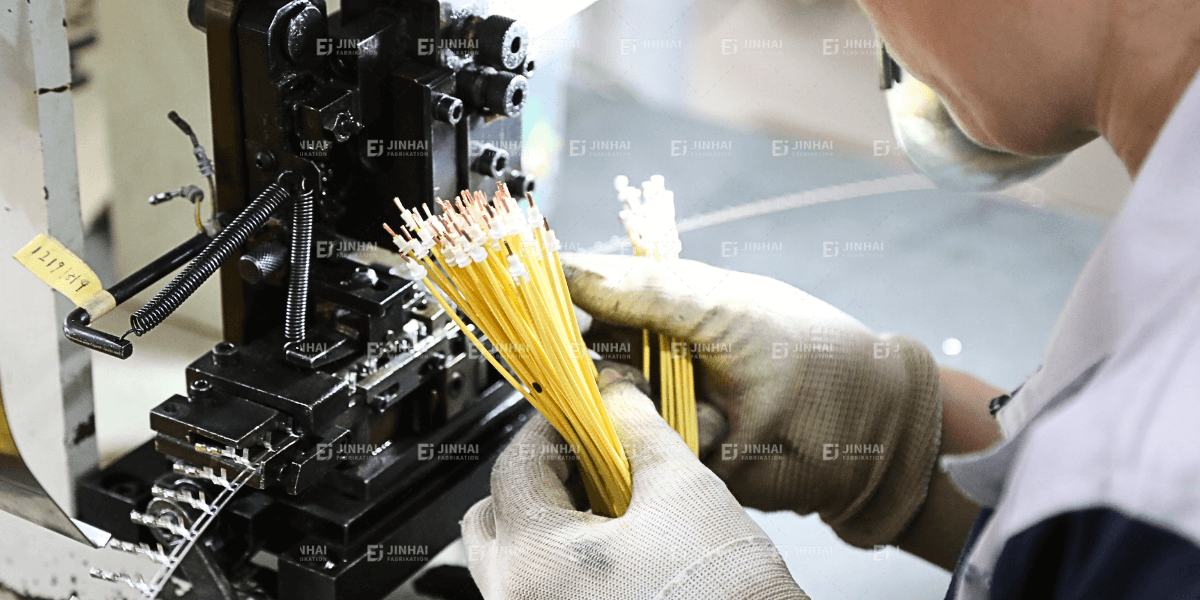

The company holds ISO9001 and IATF16949 certifications and employs 30 professional technicians. Our service scope spans automotive, motorcycle, agricultural machinery, industrial equipment, home appliances, and energy sectors. Guided by strategic development plans, we prioritize partnerships with mid-to-high-end clients while actively expanding operations to meet their customized requirements.

JinHai is headquartered in Beijing, China. The company has two business lines, wire harnesses and switches, and three production bases. JinHai is a high-tech manufacturer integrating wire harness raw materials, wire harness manufacturing, and switch manufacturing. JinHai is ISO9001 and IATF16949 certified. We have 35 professional technicians, representing 10% of our total workforce. Our development strategy is to expand our domestic sales presence and expand our export presence. We focus on partnering with and actively developing high-end clients.

Large Wiring Harness Business Line

JinHai’s large wiring harness production base specializes in manufacturing automotive and agricultural machinery wiring harnesses. Its core business areas include automotive electrical system wiring harnesses and agricultural machinery electrical and driveline system wiring harnesses. JinHai supplies instrument wiring harnesses, chassis wiring harnesses, body wiring harnesses, and trailer wiring harnesses to renowned domestic and international companies. We specialize in manufacturing services for ODM/OEM clients.

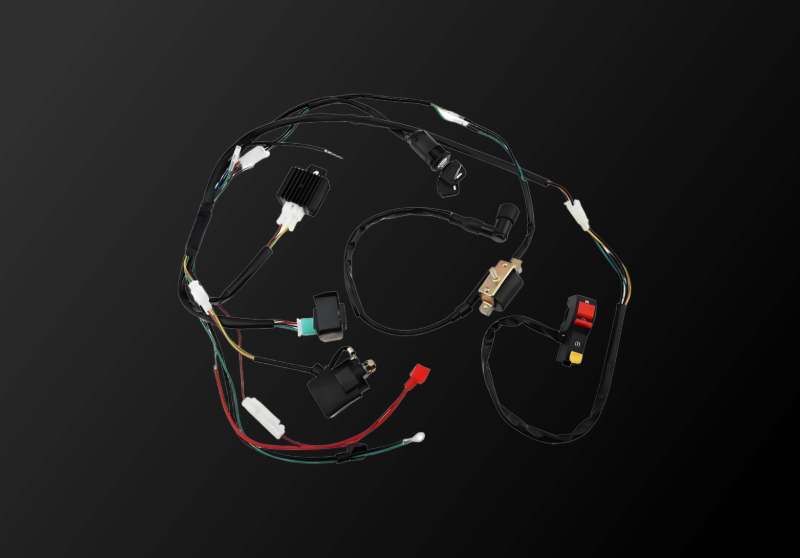

Motorcycle/Household Wiring Harness Business Line

JinHai’s motorcycle/home wiring harness business line specializes in the manufacturing of motorcycle and smart home wiring harnesses. Its core business areas include motorcycle electrical system wiring harnesses (main wiring harnesses, steering wiring harnesses, engine wiring harnesses, etc.) and wiring harnesses for essential household appliances. Since its inception, JinHai has provided air conditioning wiring harnesses, television wiring harnesses, small appliance wiring harnesses, motorcycle main wiring harnesses, steering system wiring harnesses, and other products to renowned domestic and international companies (such as Haier, Midea, Fotile, and Suzuki). JinHai specializes in providing ODM/OEM manufacturing services.

Car and Household Switch Business Line

JinHai’s switch business line specializes in manufacturing automotive and smart home switches. Its core business areas include automotive-grade ventilation, heating, and massage switches, as well as starter switches for small appliances. JinHai supplies renowned domestic and international brands, including Toyota’s single-dial and dual-dial ventilation and heating switches, Joyoung soymilk maker switches, and Supor appliance switches. We are dedicated to providing the highest-quality manufacturing services for the automotive and home appliance industries.

Automotive Wiring Harness

Motorcycle Wiring Harness

Agricultural Machinery Wiring Harness

Smart Home Wiring Harness

Automotive Switch

How Can We Help You?

24-hour quote

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradise

Customize various wiring harnesses

We provide one-stop automotive wiring harness customization services, such as engine compartment wiring harnesses, body wiring harnesses, seat wiring harnesses, door panel wiring harnesses, smart cockpit wiring harnesses, etc.

We can customize various types of switches according to customer needs, from quick switch prototyping to mass production.

We have experience in handling complex custom parts, we offer a variety of solutions and have successfully handled more than 50 customer requests.

We offer practical production solutions for your prototype designs and can manufacture samples within 1 week.

We adopt industry-leading practices to deliver premium service quality and user experience.

Guided by a zero-defect quality philosophy, we pay meticulous attention to every detail in our work.

Our employees are our most vital asset and greatest treasure.

A workplace culture built on mutual respect significantly enhances employee satisfaction.

A comfortable working environment fosters stronger team cohesion.

Benefiting from low employee turnover, we consistently retain experienced and exceptional talent.

Our culture of collaboration, openness, motivation, and mutual support drives continuous personal growth, enabling employees and the company to advance together.

For more than 20 years, we have worked closely with many outstanding clients, helping each of our partners to grow their business and develop their careers.