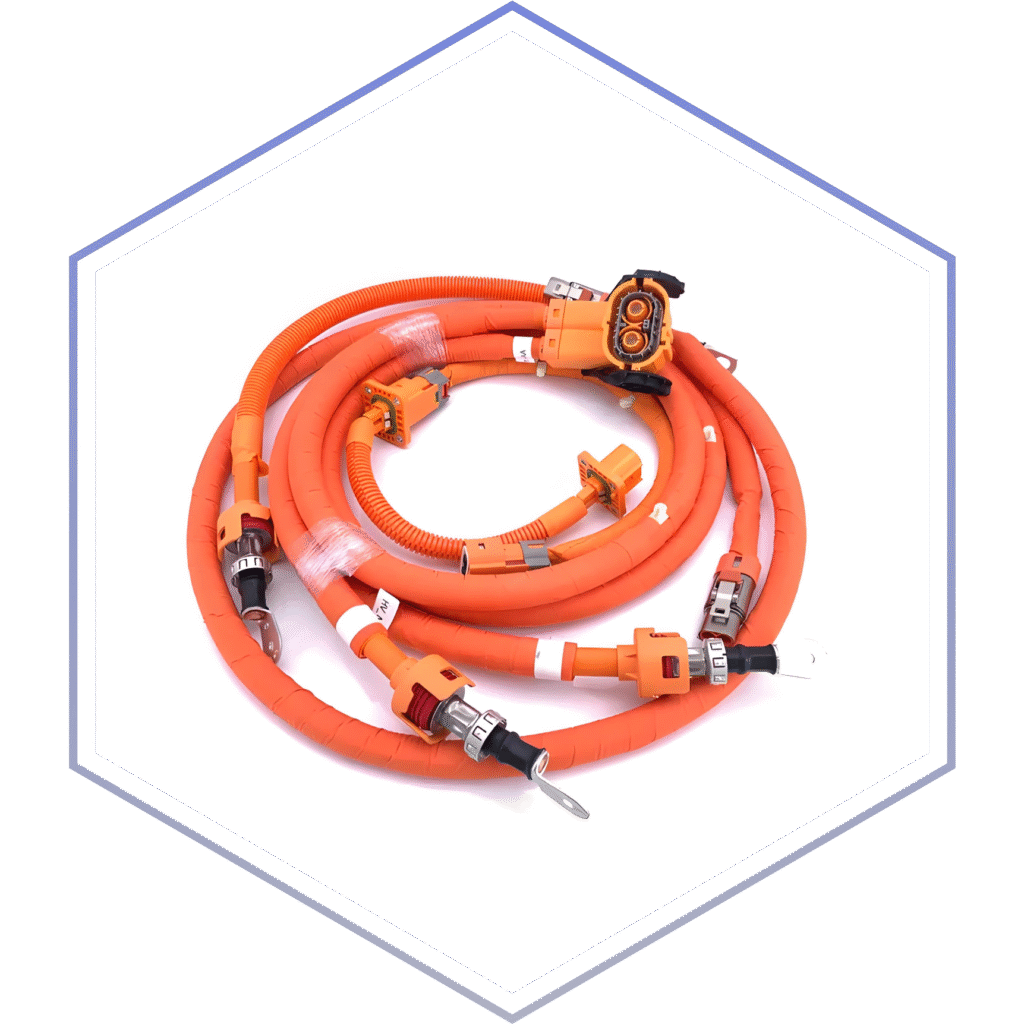

Agricultural Machinery Wiring Harness and component

JinHai manufactures high-quality wiring harnesses and components for agricultural machinery, featuring exceptional reliability in design, compliance with regulations, and adherence to industry standards.

Our Amazing Clients

JinHai possesses over 15 years of experience in custom cable and wiring harness manufacturing. The wiring harnesses we design and produce ensure reliable and stable operation of tractors, agricultural equipment, and other farm machinery even in harsh environments.

Why Choose JinHai ?

JinHai is the preferred wire harness manufacturer for numerous automotive companies for the following reasons:

Customized Solutions

Our wiring harness features a dustproof and waterproof design, enabling it to easily withstand various weather conditions and vibration environments.

Extensive Experience

With decades of design expertise, JinHai has earned a strong reputation among wiring solution manufacturers. We provide comprehensive protection solutions for a wide range of heavy machinery.

Climatic

We select only the highest-quality materials and components to ensure our wiring harnesses can easily withstand extreme weather conditions. Our products resist damage from rain, UV exposure, and dust, delivering consistent and reliable performance.

Knowledge Base

Our design team possesses extensive experience in agricultural wiring solutions. We strictly adhere to the IPC/WHMA-A-620 E Edition standard and ensure our products are built to last, meeting the demands of the modern agricultural industry.

One-on-One Service

We provide one-on-one service throughout the entire process from design to production.

Diverse Options

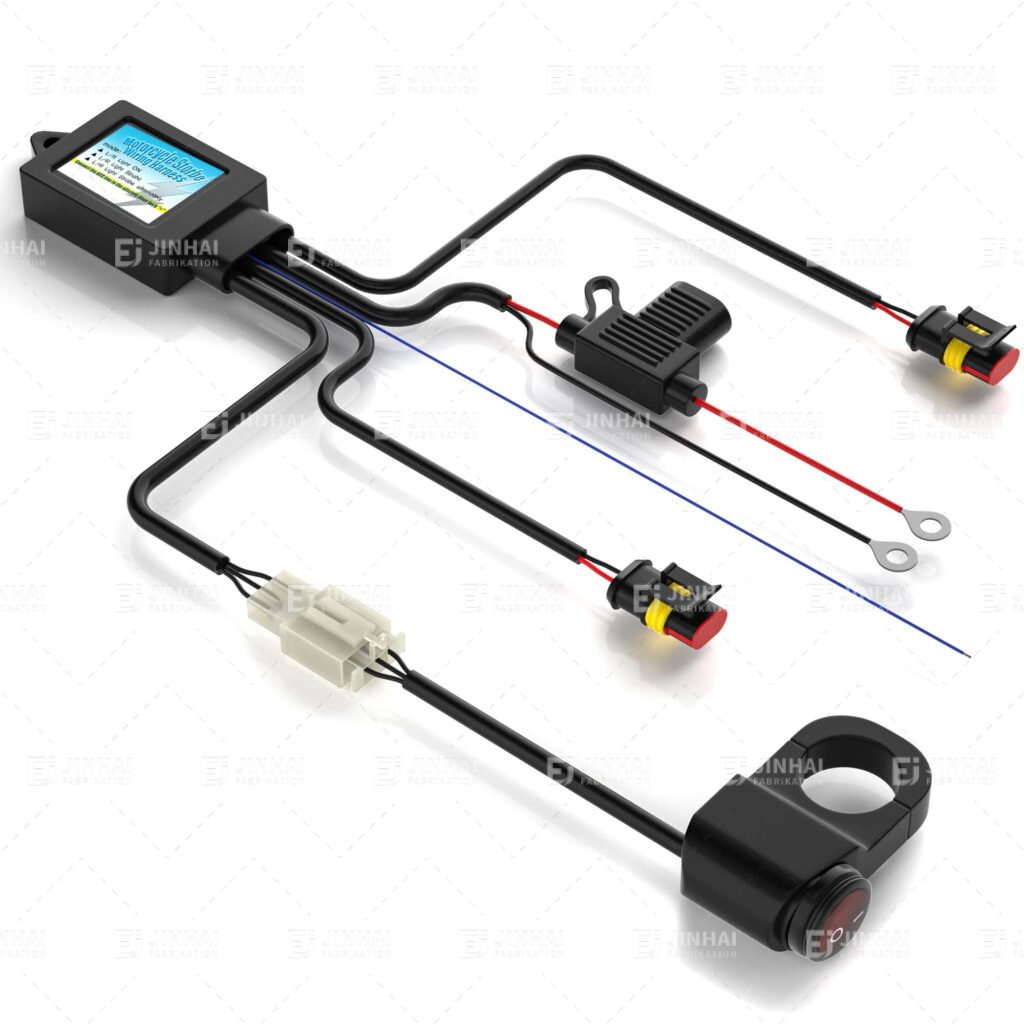

JinHai manufactures wiring harnesses based on your designs, offering maximum flexibility with alternative solutions for new energy vehicles, natural gas vehicles, hybrid vehicles, gasoline vehicles, and more.

Service Offerings

We provide comprehensive solutions with custom support. This includes:

- Wire cutting

- Stripping

- Crimping

- Soldering

- Termination.

Design Services

Our design team collaborates closely with clients throughout the design process to gain a deep understanding of their needs. This enables us to create and conduct digital testing, which can save them significant costs.

Advantages

Choosing JinHai’s agricultural wiring harnesses offers the following benefits:

- Flexible installation options

- Reliable connection stability for long-lasting durability

- Resistance to high-temperature steam baking and UV exposure

- RoHS compliance

- Weatherproof safety belts suitable for diverse agricultural environments (requires separate page)

- Customized solutions for various agricultural equipment

- Rigorous quality inspections ensure product reliability

Custom Content

JinHai offers a variety of customizable solutions to precisely meet your requirements. For example:

- A range of cables and connectors tailored to your specific needs

- Branding with custom colors to distinguish your identity

- Cable jackets composed of multiple materials, including cable ties, sleeves, electrical tape, braided webbing, and pull straps.

Functional Testing

All our agricultural wiring harnesses undergo rigorous functional testing to ensure the electrical integrity, safety, and reliability of our products. We also perform 100% quality inspections to guarantee that every item meets industry standards, ensuring consistent performance throughout your usage.

Quality and Safety, Guaranteed

Our agricultural machinery wiring harness assemblies are certified to ISO 9001:2015 and ITAR standards, meeting the highest global quality benchmarks, including those of the United States and Canada.

What Our Customer Say

JinHai Professional Custom Agricultural Machinery Wire Manufacturer

JinHai provides customized wiring harness solutions for agricultural machinery, ensuring precise compatibility with equipment models and sensor interfaces.

Utilizing premium protective materials and stringent quality control during production, our harnesses deliver outstanding high-temperature resistance, vibration resistance, corrosion resistance, and interference immunity, providing stable electrical systems for equipment.

Agricultural machinery wiring harnesses withstand harsh field conditions including intense vibration, oil contamination, dust, and temperature/humidity fluctuations.

JinHai delivers stable electrical connections through precision customization for diverse agricultural machinery models and sensors, significantly enhancing equipment efficiency and reliability.

- Safety & Reliability: Utilizes flame-retardant, corrosion-resistant materials with strictly compliant wiring to ensure long-term stable electrical performance.

- Adaptability: Exceptional shock resistance, moisture protection, and dustproofing guarantee uninterrupted operation of lighting systems.

- Efficient Maintenance: Standardized modular design with clearly marked interfaces.

- Compatibility: Pre-configured standard interfaces for specific agricultural machinery models enable seamless equipment integration.

JinHai wiring harnesses are specifically engineered for the demanding conditions of agricultural machinery. They lead the market with outstanding advantages.

- Stable Performance: Wires withstand wind, sunlight, dust, mud, and vibration without wear, breakage, or short circuits, ensuring reliable engine operation and continuous running.

- Compatibility: Utilizing lossless adaptation technology, they are compatible with mainstream models for plug-and-play functionality.

- Maintenance Ease: Clear, organized wiring simplifies troubleshooting, making repairs and replacements quick and straightforward, saving time and labor.

- Standardized Design: Standardized routing minimizes risks of wire entanglement and friction-induced fires, protecting both the engine and the entire machine.

- Cost Advantage: Offers a more reliable, economical, and worry-free alternative compared to other commercial solutions.

- Tractors

- Combine harvesters

- Rice transplanters/seeders

- Irrigation equipment (e.g., diesel pumps)

- Plant protection machinery (e.g., sprayers)

JinHai agricultural machinery wiring harnesses serve diverse applications. We can provide wiring harnesses tailored to your specific requirements.

We deliver solutions that perfectly align with your needs and budget.

We can customize agricultural machinery wiring harnesses to suit your specific application. No matter how unique your requirements may be, our production process is sufficiently flexible. Furthermore, if you have strict delivery time constraints, we offer exceptionally fast response times. Rest assured.

Select any specification variant, such as the following:

- Application environment

- Functional circuits

- Dimensions

- Certification standards

- Weight

- Packaging

For more information about agricultural machinery wiring harnesses, contact us immediately.

We are a professional automotive wiring harness manufacturer in China, dedicated to providing high-quality custom solutions. We warmly welcome you to source automotive wiring harnesses from our factory at highly competitive prices.

How to customize a wiring harness that can be adapted to the electrical systems of agricultural machinery?

Our team maintains close communication with you from the design phase to ensure the design aligns with practical application. We place significant emphasis on wire gauge, dimensions, connector types, and manufacturing processes to guarantee optimal product performance.

Will my custom-made agricultural machinery wiring harness be compatible with my farm equipment?

Absolutely. JinHai can tailor wire harnesses and cable assemblies to your exact specifications. We prioritize wire gauge, length, and connector type to ensure seamless integration with your equipment’s electrical systems.

Can wiring harnesses be customized for different voltage and power loads?

Yes. Whether you require low-voltage or high-power wiring harnesses, we will tailor wire gauge specifications, insulation materials, and connector types to your specific electrical requirements.

Service

We provide one-stop services from design to production, including:

- Cutting and Shrink Tubing

- Automated Line Assembly

- Overmolding

- Testing and Quality Assurance

- Ultrasonic Welding

- Wire Crimping and Braiding

How to diagnose wiring harness issues?

One of the best ways to check for wiring harness damage is to perform a jiggle test using diagnostic tools like JPRO.

What are the common faults in wiring harnesses?

Common faults include contact corrosion or erosion, bent or missing pins, and loose connectors. For example, in automotive circuits, wiring harness plugs may experience terminal oxidation or deformation, leading to poor contact that interferes with engine signals.

What are the three types of wiring harnesses?

| Wiring Harness Type | Primary Function |

|---|---|

| Main Harness | Connects all wiring harness components into a unified circuit |

| Powertrain Harness | Covers engine and transmission interface wiring |

| HVAC Harness | Powered heating, ventilation, and air conditioning modules |