Why Choose Custom Lighting Harnesses?

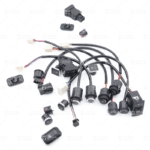

The value of custom lighting harnesses lies in delivering solutions that meet diverse customer needs, providing more application options while balancing product costs.

- Application Scenarios: JinHai selects optimal conductors, insulation materials, and connectors based on equipment-specific voltage, current, and operating environments.

- System Reliability & Safety: Maximizes electrical connection stability through optimized routing paths, precise bend radius calculations, and stress-relief structural designs, ensuring product longevity and safety.

- Enhanced Installation Efficiency: Custom harness lengths, branches, and interfaces perfectly match target equipment, enabling straightforward, high-efficiency installation and reducing installation failure rates.

Custom Lighting Harness: Manufacturing Critical Points

Every stage of custom lighting harness design and manufacturing must strictly adhere to technical specifications and quality standards.

Design Solution Key Points:

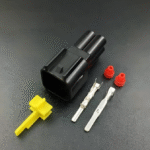

- Materials: Select conductors, insulation layers, jackets, and connector terminals from diverse materials based on application environment, performance, and cost requirements.

- Wiring & Electrical: Design drawings clearly define the harness’s 3D layout, mounting points, and protective measures, ensuring power, signal, and data lines meet electrical standards.

- Industry Standards: Custom harnesses strictly adhere to IPC/WHMA-A-620 standards while complying with diverse international and regional certification requirements.

- Manufacturing & Quality: JinHai enables full traceability from raw material intake through production processing to final testing. Automated equipment elevates production standards, while rigorous electrical testing ensures 100% compliance for every harness.

Custom Lighting Harnesses: Application Areas

Smart Buildings & IoT: Custom lighting harnesses form the circuit foundation for smart home experiences. Smart lighting solutions supporting Bluetooth Mesh or open API interfaces require custom lighting harnesses to ensure stable data and power transmission.

Industrial Automation: Custom lighting provides stable, flicker-free power for machine vision systems. Specialized cables and connectors—highly flexible, wear-resistant, and interference-proof—are custom-engineered. Modular harness design simplifies maintenance and troubleshooting, ensuring reliable equipment operation.

Conclusion

Custom lighting harnesses deliver optimized solutions for complex lighting systems.

JinHai is a global manufacturer specializing in customized wiring harness solutions. We possess advanced manufacturing equipment and stringent production/process protocols, while strictly adhering to IATF16949 and ISO9001 quality management systems.

Choose JinHai to accelerate your project’s success. JinHai grows alongside your projects!