Medical Harnesses Certification Standards

Medical harness certification standards are characterized by multiple standards and cross-regional applicability. Core standards cover electrical safety, biocompatibility, and regional market access requirements.

IEC 60601 Series Standards

IEC 60601 is the globally recognized authoritative standard system for safety and performance requirements of medical electrical equipment. This standard features multiple standards with broad coverage:

- Core Standard IEC 60601-1: Defines standards for electrical safety, mechanical safety, fire performance, electromagnetic compatibility (EMC), and radiation protection for medical electrical equipment (including cable assemblies).

- Device-Specific Standards: The IEC 60601-2-x series provides detailed requirements for specific medical device types to address particular operational scenarios.

- EMC Sub-Standards: IEC 60601-1-2 establishes quantitative metrics for shielding effectiveness and interference immunity in wiring harnesses.

JinHai manufacturers can provide technical documentation proving that “basic performance” remains maintained under single-fault conditions.

ISO 10993 Biocompatibility Assessment

The ISO 10993 series focuses on evaluating biological risks when medical device materials come into contact with the human body, serving as a critical basis for selecting materials in medical wiring harnesses.

UL Certification and North American Market Access

UL certification is a mandatory safety requirement for entering the North American market.

- UL 60601-1 Standard: Incorporates U.S. national differences within the core safety framework, such as specific marking requirements and power supply system adaptability. JinHai products can achieve UL 60601-1 certification and obtain FDA market access approval.

- UL ZPFW2 Certification: Covers wire harness assemblies, encompassing manufacturing process quality control, material traceability, and consistency requirements.

- Connector and Cable Standards: Establishes specialized standards UL 1977 for connectors and UL 758 for cables.

Component Material Specifications for Medical Harnesses

Material selection for medical harnesses balances biocompatibility, sterilization tolerance, mechanical properties, and cost.

Conductor and Insulation Materials

- Conductor Materials: Medical-grade oxygen-free copper or silver-plated copper are common choices, ensuring low impedance and high signal integrity.

- Insulation Materials:

- Thermoplastic Polyurethane : Offers excellent mechanical strength, abrasion resistance, and chemical tolerance. Passes ISO 10993-10 sensitization testing, suitable for high-wear environments.

- Silicone: Exceptional biocompatibility with a wide temperature range (-60°C to +200°C). Withstands hundreds of high-temperature, high-pressure steam sterilization cycles, making it the optimal choice for medical device harnesses.

- Thermoplastic Elastomers: Lower processing costs and improved recyclability while retaining silicone’s biocompatibility and sterilization capability.

- Fluoropolymers: Exceptional chemical inertness, resistant to strong acids, alkalis, and disinfectants.

- Polyvinyl Chloride : Cost-effective disposable material.

Protective Layer Materials

- Material Properties: Antimicrobial coating, antistatic properties, low-friction surface, and color-coded differentiation.

- Sterilization Methods:

- High-temperature steam sterilization: Suitable for silicone, certain high-performance TPU, and PEEK composites.

- Low-temperature plasma sterilization: Suitable for TPU, TPE, and certain fluoropolymers.

- Irradiation sterilization: Suitable for TPU and silicone.

- Ethylene oxide sterilization: Silicone and TPE exhibit superior ETO sterilization efficiency compared to porous materials.

- Single-use strategy: Single-use harnesses may use PVC or PE to reduce costs, without sterilization tolerance considerations.

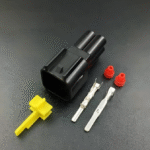

Connectors and auxiliary materials

- Connector materials: Medical-grade PEEK or stainless steel housings; gold-plated contacts enhance disinfectant resistance and mating cycles. Sealing rings use FDA-grade fluorocarbon rubber or medical-grade silicone.

- Adhesives and Coatings: All auxiliary materials must pass biocompatibility assessments.

Medical Harnesses Customized Design

Medical Harness Production Steps:

- Material Selection: Utilize high-quality, medical-grade wires to ensure harness stability and reliability in medical devices.

- Reference Design: Determine design and structure based on medical and electronic device requirements to guarantee conductivity, interference resistance, and anti-static properties.

- Wire Processing: Form core harness structures through cutting, stripping, stranding, and winding.

- Outer Sheathing: Enhance kink resistance and cut resistance via specialized outer sheathing, plastic protection, and tubing filling.

- Terminal Crimping: Perform terminal crimping using air crimpers, riveting machines, mechanical pliers, etc.

- Post-Processing: Includes cleaning, inspection, color coding, packaging, and visual acceptance. Final products undergo inspection before delivery to customers.

Application Scenario Definition

- Contact Site Classification: Directly determines biocompatibility testing levels and material selection based on whether the harness contacts skin surfaces, mucous membranes, blood pathways, or is implanted.

- Dynamic Environment: Surgical robot harnesses require ultra-high flexibility; MRI equipment harnesses demand non-magnetic design; dialysis machine harnesses must withstand chemical corrosion.

- Sterilization Method Pre-Confirmation: Sterilization methods must be confirmed with hospital infection control departments during design to prevent material incompatibility issues after finalization.

Challenges in Small-Batch Customization

Medical wire harnesses often follow a small-batch, high-variety production model:

- Flexible production line configuration: Utilize modular molds and quick-change equipment to reduce small-batch costs.

- Prototype validation adequacy: Large-scale statistical validation is impractical for small batches; employ over-testing strategies by increasing sample size and rigor to ensure confidence.

- Documentation Package Integrity: Even for small batches, prepare complete technical documentation packages for each custom model—including material certificates, test reports, and risk analyses—to meet FDA or CE review requirements.

Medical Harnesses Conclusion

Medical wire harness customization demands specialized domain expertise, with processes strictly adhering to early standard implementation, material selection, and rigorous validation criteria.

JinHai is a global manufacturer specializing in customized wiring harness solutions. We possess advanced manufacturing equipment and stringent production/process protocols, while strictly adhering to IATF16949 and ISO9001 quality management systems.

Choose JinHai to accelerate your project’s success. JinHai grows alongside your projects!