AI Field Wire Harnesses Customization: Pain Points and Solutions

High-Temperature Operating Environments

Pain Point: High internal voltages and elevated product temperatures within AI servers. Wire harness design and routing directly impact heat dissipation efficiency.

Solution

- Routing Paths: Server interiors offer limited space. Custom harnesses must optimize routing to maximize airflow and prevent power degradation from inadequate cooling.

- Temperature-Resistant Materials: Insulation and sheathing must withstand prolonged exposure to high temperatures.

- Liquid Cooling Integration: Liquid cooling has become the mainstream solution for AI server thermal management. Custom harnesses must ensure compatibility with cooling plates and tubing. Select corrosion-resistant sheathing materials to prevent coolant leaks from compromising harness performance.

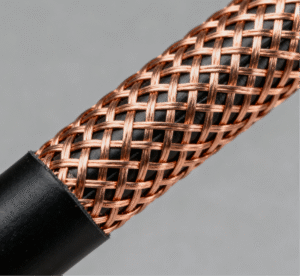

Electromagnetic Interference

Pain Point: High-speed communication harnesses in AI products require robust EMI resistance to prevent interference.

Solutions

- Shielding Materials & Structure: Implement effective EMI shielding using graphene foam or conductive polymers to ensure signal integrity while maintaining flexibility.

- Shielding System Design: Consideration must be given to harness layout, grounding screw placement, PCB design, and structural design during the design phase. Position the harness as far as possible from interference sources such as high-frequency cables and switching power supplies.

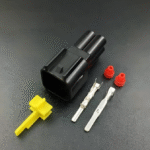

- Connectors: Select high-speed connectors with metal housings and excellent shielding performance.

Flexibility

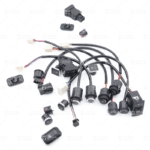

Pain Point: Limited internal space in AI products demands excellent flexibility and pliability from the harness.

Solutions

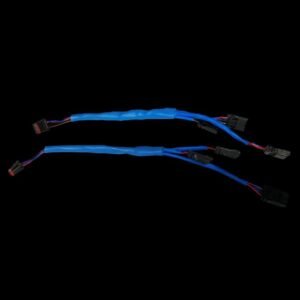

- Modularization: For large-scale AI data center deployments, factory-modularized harness installation significantly reduces on-site deployment time while minimizing human error failures.

- Miniaturization: Selecting ultra-fine cables, thinner insulation layers, and miniaturized connectors is crucial for routing in confined spaces.

- Flexibility and Stress Management: Custom harnesses must specify minimum bend radii to prevent internal damage during tight-space routing. Incorporate stress relief mechanisms at connector ends and mounting points to protect crimped connections from pull-out and vibration failures.

AI Field Wire Harnesses Core Performance

- High-Speed Signal Transmission: For high-speed protocols like Ethernet, signal integrity is a critical standard.

- Electrical and Mechanical Performance: The electrical and mechanical properties of the harness form the foundation for long-term, stable device operation.

AI Field Wire Harnesses: Customization Strategies by Application

Harness customization solutions must accommodate diverse application scenarios. Cost is a key metric for harness solutions, encompassing procurement expenses and operational costs like deployment, maintenance, failure resolution, and upgrades.

- AI Data Centers: Utilize high-quality, modular harnesses to reduce deployment time and maintenance costs.

- Micro-Terminal Devices: Employ harnesses meeting premium certification standards as the optimal strategy to prevent repairs and ensure product quality.

- Autonomous Driving/In-Vehicle AI: Leverage order volume and automated production to lower manufacturing costs while mandatorily selecting materials with high-quality certifications.

Conclusion

In the AI era, premium AI harnesses are critical components determining product performance, reliability, and cost-effectiveness.

JinHai is a global manufacturer specializing in customized wiring harness solutions. We possess advanced manufacturing equipment and stringent production/process protocols, while strictly adhering to IATF16949 and ISO9001 quality management systems.

Choose JinHai to accelerate your project’s success. JinHai grows alongside your projects!

Contact us immediately to learn how we can meet your cable and harness requirements. Follow us on Youtube .