Wire harness, as the core component of equipment power transmission and signal interaction, is very easy to become the source and receiver of EMI/RFI emission. So the harness shielding technology, as the core means to combat electromagnetic interference, its importance is self-evident. Next by 12 years as a harness design experts, I will be your harness shielding technology for a comprehensive analysis.

Chapter 1: Definition, necessity and basic principles of wire harness shielding

What is wire harness shielding?

Harness shielding, in short, is in the cable or wire harnesses wrapped around the outside of a layer of electrically conductive or magnetically conductive material composed of a sheath, the sheath and the reference ground in the circuit (usually the equipment chassis) is connected, thus constituting a complete electromagnetic isolation system. This sheath, known as the “shield”, is not itself the main pathway for current in the harness, but is specifically designed to manage and control electromagnetic fields. Unshielded wires in the transmission of high-frequency signals or electricity, will radiate electromagnetic energy to the surrounding space, becoming a source of interference; at the same time, they will also capture the electromagnetic from the outside world, resulting in signal distortion or equipment action error. The core role of the shield is to provide a low impedance discharge channel for these electromagnetic energies to be channeled into the earth, thus protecting the stability of the internal wires when transmitting core signals or electricity.

Why do I need wire harness shielding? –The Electromagnetic Compatibility (EMC)

Challenge Due to the severe electromagnetic forces that modern electronic devices face, it is essential that wire harnesses are shielded. The goal is to achieve electromagnetic compatibility (EMC), which consists of two requirements: Electromagnetic interference (EMI) emissions: equipment during normal operation, its internal wiring harness and circuitry should not generate electromagnetic nuisance exceeding specific limits, so as not to affect the normal operation of other equipment in the same. Electromagnetic immunity (Immunity): equipment in the electromagnetic harassment from the outside, should have a certain resistance, can its inherent performance normal operation. Lack of effective shielding of the harness, is unable to pass the EMC regulations certified. The consequences of the light audio and video signals appear noise, noise, heavy industrial control systems can be triggered by misoperation, automotive safety systems failures, diagnostic errors in medical equipment, and even endanger the safety of life.

Basic Principles of Shielding: Absorption and Reflection

Wiring harness shielding primarily achieves its function through two mechanisms:

①. Reflective loss of shielding material: Reflective loss primarily targets low-impedance electric fields and plane wave interference.

②. Absorption loss in shielding material: Electromagnetic waves penetrating the shielding material convert electromagnetic energy into thermal energy, which is dissipated and absorbed. The intensity of absorption loss depends on the thickness, electrical conductivity, and magnetic permeability of the shielding material.

An effective shielding design results from the combined action of both reflection and absorption mechanisms.

Chapter 2: Primary Types, Characteristics, and Application Scenarios of Wire Harness Shielding

Based on the structure, materials, and manufacturing processes of the shielding layer, wire harness shielding can be primarily categorized into the following basic types, each possessing unique advantages and applicable domains.

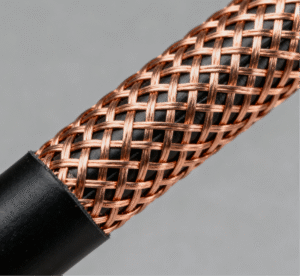

Braided Shielding

Definition and Structure: Braided shielding consists of a mesh sleeve formed by interweaving multiple strands of fine metal wire (typically tinned copper wire, bare copper wire, or aluminum alloy wire) in a specific pattern. It covers the insulated core wires or inner sheath of a cable, offering excellent flexibility and fatigue resistance.

Advantages:

- Interference Resistance: For electromagnetic interference in the mid-to-high frequency range, the braided layer provides stable and low electromagnetic impedance due to its mesh structure, delivering excellent shielding performance.

- Flexibility: The braided structure enables the cable harness to withstand frequent bending and stretching, maintaining stable signal transmission even in vibrating environments.

Disadvantages:

- Coverage limitations: Due to its mesh structure, the braided layer cannot achieve 100% shielding coverage, leaving minute gaps. The shielding coverage rate (typically between 70% and 95%) is unsuitable for low-frequency shielding environments.

- Heavy and Bulky: Compared to other shielding methods, achieving equivalent shielding performance often requires heavier, thicker materials for the woven layer.

- Higher Cost: The weaving process is complex and consumes more materials, resulting in relatively higher costs.

Typical Application Scenarios:

- Automotive Industry: Sensor harnesses in engine compartments, ABS/ESP system wiring harnesses, audio/video wiring harnesses for in-vehicle entertainment systems.

- Aerospace: Various cabin control harnesses and data buses (e.g., ARINC 429).

- Industrial Automation: Robot joint harnesses, servo motor power and signal feedback cables.

- Professional Audio/Video: High-quality microphone cables, audio interconnects, SDI video cables.

2.2 Helical Shielding (Spiral Shielding)

Definition and Structure: Helical shielding involves tightly winding one or more metal tapes (typically aluminum-plastic composite tape) or flat metal wires in a spiral pattern along the cable’s axial direction around the core conductor. Its structure resembles a spring.

Advantages:

- Exceptional Flexibility and Bendability: The spiral structure provides the cable with an outstanding minimum bend radius, making it highly suitable for applications requiring repeated, tight-radius bending.

- Lightweight and Cost-Effective: Requiring relatively little material and featuring a simple manufacturing process, it serves as an economical solution for basic shielding.

Disadvantages:

- Directional shielding effectiveness: Provides good shielding for electromagnetic waves propagating along the cable axis; however, for waves incident from the side (radially), gaps between the coils cause shielding effectiveness to decline sharply with increasing frequency.

- Low mechanical strength: The helical structure is prone to deformation or even crushing under tensile or compressive forces, leading to shielding failure.

- Average low-frequency shielding performance: Primarily relies on reflection loss, exhibiting weaker shielding capability against low-frequency magnetic fields.

Typical Application Scenarios:

- Consumer Electronics: Internal flex cables for devices such as mice, keyboards, and headphones.

- Medical Devices: ECG lead wires and patient monitor cables, which require frequent coiling and movement.

- Low-Frequency, Low-Intensity Data Signal Cables: Such as certain RS-232 and RS-485 communication cables.

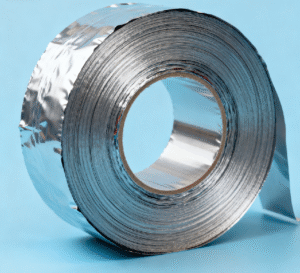

2.3 Aluminum-Plastic Composite Tape Shielding

Definition and Structure: This is a tape-type shielding composed of a thin aluminum foil layer laminated with an adhesive to a layer of polyester (PET) or polypropylene (PP) plastic film. During application, the composite tape is wrapped longitudinally around the core conductor, typically with the aluminum side facing inward. A bonding wire (bare copper or tinned copper) is connected to the aluminum surface before the entire assembly is grounded. This configuration addresses grounding issues caused by the aluminum foil’s susceptibility to fracture.

Advantages:

- 100% shielding coverage: Exceptional electromagnetic interference resistance, suitable for high-frequency electromagnetic interference environments.

- Lightweight and space-saving: Ultra-thin aluminum foil reduces overall cable outer diameter, ideal for high-density cabling.

- Extremely low cost: One of the most cost-effective shielding methods available.

- Moisture resistance: Aluminum layer effectively blocks water vapor penetration.

Disadvantages:

- Poor flexibility and durability: Aluminum foil has low ductility and is prone to cracking or even breaking after repeated bending, leading to permanent degradation of shielding performance. Therefore, it is unsuitable for dynamic applications.

- Higher transfer impedance: Aluminum has lower electrical conductivity than copper, and the film is very thin, resulting in higher DC resistance. This limits shielding effectiveness, particularly at low frequencies.

- Termination challenges: Specialized grounding techniques and connectors are required to ensure reliable grounding of the aluminum foil layer.

Typical Application Scenarios:

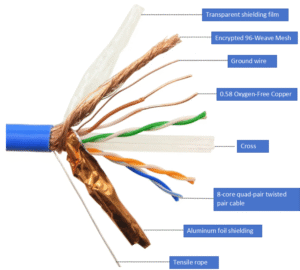

- Ethernet Cables (UTP/STP): Overall shielding for twisted pairs (e.g., F/UTP, S/FTP).

- Coaxial Cables: As part of the outer conductor.

- Fixed Installation Cables: Structured cabling systems within buildings, security surveillance system cables.

- Consumer Electronics: Single-pair or overall shielding within HDMI cables and USB cables.

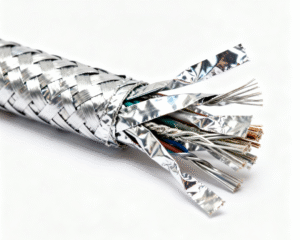

2.4 Composite Shielding

Composite shielding technology is a high-performance shielding solution designed for extreme electromagnetic environments, combining the aforementioned basic shielding methods.

Common combinations:

- Aluminum Foil Shielding + Braided Shielding (SF/UTP or PiMF): This is the most common and effective composite shielding configuration. The inner layer uses aluminum foil shielding, providing 100% coverage to effectively suppress high-frequency interference. An outer layer of braided shielding is then wrapped around it, offering mechanical protection, reliable grounding, and excellent shielding capability at medium and low frequencies.

- Double-layer braided shielding: Employed in demanding applications such as professional broadcast equipment and military domains. Two braided layers further minimize gaps in the shielding envelope, delivering significantly higher shielding effectiveness than single-layer braiding.

- Multi-layer aluminum foil shielding: Utilized in scenarios requiring extreme high-frequency isolation, such as high-speed differential signal lines.

Advantages:

- Exceptional shielding effectiveness: Combines the strengths of various shielding approaches to deliver outstanding shielding exceeding 90dB or even 120dB across an extremely wide frequency range (from low to high frequencies).

- High reliability: Redundant design ensures effective protection persists even if one shielding layer is compromised.

Disadvantages:

- Highest Cost: Significantly increased material and processing expenses.

- Maximum Weight and Diameter: Cables become rigid with larger bending radii.

- Complex Termination Process: Requires careful handling of each shield layer and proper grounding.

Typical Application Scenarios:

- Aerospace and Defense: Flight control systems, radar systems, and encrypted communication equipment.

- Medical Imaging: Signal cables within MRI (magnetic resonance imaging), CT scanners, and other devices that are extremely sensitive to noise.

- Industrial Test and Measurement: High-precision data acquisition systems.

- High-Performance Computing and Data Centers: High-speed, low-latency interconnect systems.

Chapter 3: Analysis of Relationships and Interoperability Among Wiring Harness Shielding Methods

Performance Evolution and Complementary Relationships

Different types of wiring harness shielding methods are not mutually exclusive but exhibit clear evolutionary progression and complementary relationships in performance.

- From Basic to High Performance: This represents a distinct technological progression.

- Wrapped Shielding: Provides the most fundamental flexible shielding, serving as the entry-level choice for dynamic applications.

- Aluminum Foil Shielding: Delivers optimal cost-performance for static high-frequency shielding.

- Braided Shielding: Achieves the best balance between dynamic applications and overall performance, serving as the backbone of industrial standards.

- Composite Shielding: Represents the pinnacle of shielding technology, offering the ultimate solution for the most demanding applications.

- Complementary advantages form the foundation of composite shielding: As seen in composite shielding, aluminum foil’s “full coverage” perfectly compensates for woven mesh’s “gaps”; while the woven layer’s “high strength” and “easy grounding” overcome aluminum foil’s ‘fragility’ and “grounding challenges.” This synergistic effect, where 1+1>2, forms the core logic for selecting solutions in engineering design.

Can Different Wiring Harness Shielding Methods Be Interchanged?

This is a critical practical question. The answer is: Under specific conditions, different shielding methods can and often are used in combination. However, this is not a simple “interchangeability,” but rather an “interoperability” based on systematic EMC design.

Scenarios and Feasibility of Combined Use

In real-world engineering, scenarios involving mixed shielding methods are highly common, primarily manifesting in two dimensions:

Shielding selection for different harnesses within the same system:

A complex electronic system (such as an automobile) contains multiple harnesses with distinct functions. Engineers select the most suitable shielding method for each harness based on the nature of the transmitted signals, the electromagnetic environment, mechanical performance requirements, and cost control.

Multi-layer shielding on a single harness (composite shielding):

This represents the most direct form of “interoperability.” Combining aluminum foil and braided layers on a single cable inherently achieves the deepest level of “interoperability” between these two shielding methods. This necessitates connector designs and termination processes capable of effectively handling both shielding layers simultaneously, ensuring reliable grounding for each.

Considerations and Challenges During Interchangeability

“Interchangeability” typically refers to replacing one type of shielded cable with another during design changes or maintenance. This practice demands extreme caution and requires comprehensive evaluation:

- EMC Performance Matching: Never simply substitute a high-performance shield (e.g., braided or composite) with a lower-performance shield (e.g., wrapped shield) from the original design. EMC testing must be repeated to ensure the system still meets regulatory requirements. Conversely, while upgrading from low-performance to high-performance shielding is generally safe, it often leads to unnecessary cost increases, added weight, and installation complications.

- Mechanical and Physical Properties: Shielding type directly impacts cable flexibility, bend radius, weight, and outer diameter. Replacement may render cables incompatible with existing cable trays or mounting clips, or cause premature failure in dynamic applications due to mismatched flexibility.

- Termination and Grounding Practices: Different shielding methods require distinct termination approaches. Switching from braided shielding to foil shielding necessitates a complete overhaul of grounding techniques. If connectors do not support reliable foil grounding, the shielding becomes ineffective.

- Cost and Supply Chain: Interchangeability may introduce cost fluctuations and supply chain risks, necessitating clear specifications early in the project.

- Conclusion: Interoperability between shielding methods is feasible, but it constitutes a conditional “cooperative design” guided by system-level EMC principles and grounded in deep understanding of each method’s characteristics—not a simple plug-and-play replacement. Any modification must be backed by rigorous test data.

Chapter 4: Conclusions and Outlook

Wire harness shielding is an art of balance, seeking the optimal solution among performance, cost, reliability, and manufacturability. From simple wrapped shielding to complex multilayer composite shielding, each technique holds irreplaceable value and distinct application domains.

- High-Frequency Applications: Shielding materials and novel structures for millimeter-wave bands will emerge as key research areas.

- Lightweighting and Miniaturization: Development of new nanocomposite shielding layers (e.g., graphene, carbon nanotubes) featuring higher conductivity and thinner profiles.

- Intelligent Solutions: Future “smart shielding” may incorporate self-diagnostic capabilities, enabling real-time integrity monitoring and early warnings for damage.

- Sustainability: Adopting eco-friendly, recyclable shielding materials will become a significant trend.

Summary

In summary, wire harness shielding—as a foundational technology for electromagnetic compatibility—will continue to accompany and drive every advancement in electronics. While mastering the four shielding methods above, JinHai will further explore cost-effective and high-performance shielding solutions aligned with industry development trends.