How Engine Wiring Harness Work

As the core electrical system of a vehicle, the engine harness connects the Engine Control Unit (ECU) to various sensors, actuators, and electronic modules, ensuring precise transmission of power and data.

Primary Functions of Engine Wiring Harness

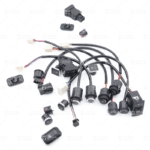

Providing safe and stable connections for the electrical system, such as:

- ECU: Acquires sensor data, processes information, and issues execution commands.

- Sensors: Receive and transmit feedback data.

- Actuators: Respond to ECU commands to execute operations.

- Power Supply: Continuously provides electrical power.

Characteristics of Engine Wiring Harness

- Extreme Environment Adaptability: Ensures long-term stable electrical system operation in harsh conditions.

- Vibration Resistance: Incorporates multi-layer elastic materials for vibration damping.

- Corrosion Resistance: Utilizes high-quality, standard-compliant materials for reliable performance in corrosive environments.

- Electromagnetic Interference (EMI) Resistance: Special manufacturing processes guarantee stable signal transmission unaffected by electromagnetic interference.

- Flame Retardancy: Utilizes fully flame-retardant materials to prevent fires caused by harness short circuits.

Common Engine Wiring Harness Failures and Causes

Common Engine Wiring Harness Failures

- Warning Light Illuminates: Sensor signal transmission not received.

- Difficult Starting: Abnormalities in the power supply circuit.

- Unstable Engine Idling: Signal transmission errors in the ignition or fuel injection system.

- Reduced Performance: Abnormal sensor data feedback.

- Burning odor: Insulation ignites due to short circuits or overheating.

Causes of Engine Wiring Harness Failures

- Aging: Severe degradation of insulation in harsh operating conditions, leading to protective layer failure.

- Vibration: Prolonged vibration causes copper core fractures or connector loosening.

- Abrasion: Friction between harness and vehicle frame causes abnormal wear on protective layers, resulting in short circuits.

- Corrosion: Harsh environments corrode connector terminals and wires.

- Quality Issues: Defects in crimping processes, materials, or design.

Impact of Engine Wiring Harness Failures

Harness problems not only impair engine performance but also pose serious safety hazards to occupants during operation:

- Performance Degradation: Reduces engine power output.

- Component Damage: Harness short circuits may burn out expensive electronic components.

- Safety hazards: Unexpected engine shutdowns during operation pose severe driving risks; wire shorts may even cause fires.

- Diagnostic challenges: Intermittent harness failures are difficult to pinpoint, increasing repair costs.

Engine Wiring Harness Repair Solutions

Depending on the fault condition, engine harness failures can be resolved through repair or replacement.

- Step 1: Fault Diagnosis: Locate the issue

- Visual Inspection: Check wiring harnesses and components for visible damage, burn marks, corrosion, or fractures.

- Read Fault Codes: Use an OBD-II scan tool to retrieve existing ECU fault codes and identify the cause.

- Electrical Testing: Use a multimeter to test circuit continuity, measure resistance between circuits and chassis ground, and verify voltage to pinpoint the fault location.

- Step 2: Determine Repair Strategy

- Localized Repair: For isolated, clearly defined faults, perform spot repairs using specialized welding and crimping tools to ensure insulation integrity.

- Harness Replacement: Replace the entire harness when severe aging, corrosion, or multiple damage points are present.

Engine Wiring Harness Maintenance Tips

Regular maintenance significantly extends engine harness lifespan:

- Routine Visual Inspection: Check harness appearance for damage.

- Maintain Cleanliness: Promptly remove engine oil residue and dust.

- Protective Coating Maintenance: Apply harness protectant to form an anti-oxidant film, delaying plastic surface aging and corrosion.

- Inspect Fasteners: Ensure harnesses are securely fastened to prevent friction damage.

- Check Connectors: Verify all connectors are fully engaged and locked.

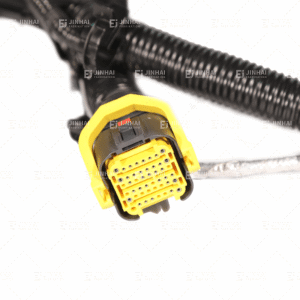

JinHai’s Custom Engine Wiring Harness Services

JinHai is a professional harness manufacturer offering standardized harnesses and custom solutions. Our team specializes in the harness industry, focusing on design and manufacturing to deliver high-quality harnesses tailored to diverse customer requirements. Every process from design to delivery is strictly controlled to ensure zero-defect delivery.

Custom Service Process

- Application Scenario: Understand customer customization needs and usage scenarios.

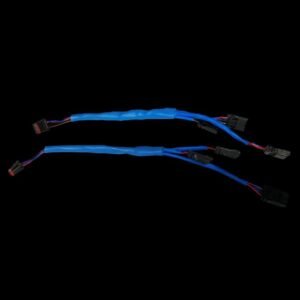

- Custom Design: Use 3D software for harness 3D modeling and routing planning.

- Material Selection: Screen materials based on application scenarios.

- Small-Batch Production: Manufacture samples for comprehensive quality inspection and testing.

- Mass Production & Delivery: Initiate large-scale production and delivery upon sample approval.

Conclusion

High-quality, safe, and reliable engine wiring harnesses are crucial for ensuring stable vehicle operation, high fuel efficiency, and driving safety. Regular inspection and maintenance help extend the service life of engine wiring harnesses.

Contact us immediately to learn how we can meet your cable and harness requirements. Follow us on Youtube .