Applications of Aluminum Conductors

Below are various applications for aluminum conductors.

- Utilities

- Aluminum has long been used across diverse utility sectors. Today, it delivers critical performance for both public utilities and commercial applications,such as data centers and urban lighting

- Commercial Buildings

- Most large commercial facilities utilize aluminum components. Due to their versatility, these aluminum cables are becoming essential materials for most high-rise buildings, high-capacity stadiums, manufacturing plants, and wastewater treatment facilities.

- Contractors

- Beyond large conductors, most contractors prefer aluminum for service entries and distribution conductors.

Benefits of Using Aluminum in Your Facility

Below are several advantages of utilizing aluminum in your facility.

Cost Savings

A primary benefit of choosing aluminum conductors is cost savings, thanks to aluminum’s low material cost. Utilizing aluminum wherever possible can yield savings of up to 80%.

However, it’s important to note that aluminum prices can fluctuate. Nevertheless, it remains significantly more favorable than copper, whose prices can surge dramatically almost overnight. Statistics show copper prices reached historic highs last year, rising approximately 91%. This situation ultimately intensified the urgency for in-depth research into alternative conductors.

Technological Design Advancements

One of the most critical advancements in aluminum conductors lies in their physical properties. The emergence of new alloys has helped overcome previous misuses of aluminum conductors. Today, they offer superior conductivity, enhanced durability, and improved creep resistance compared to earlier versions.

Additionally, aluminum conductors boast a significant advantage in weight—approximately 50% lighter than copper counterparts. This characteristic facilitates easier installation, particularly for tasks like pulling, bending, and routing wires in confined spaces.

Another compelling reason for contractors to use aluminum conductors is their NEC approval. This signifies compliance with the standards outlined in NEC Article 310.14, which mandates that aluminum conductors be manufactured from AA-8000 series electrical-grade aluminum alloy conductors.

Where Can I Use Aluminum?

Aluminum conductors can be used in various scenarios depending on your project. Some projects utilize aluminum conductors between transformers and distribution panels at the service entrance. They can also be installed in distribution panels connected to motor control centers for feeder applications. Aluminum conductors may also be used between distribution panels and feeders, provided space constraints are considered.

Aluminum Application Considerations

For most contractors, conductivity is a key concern they frequently address, and aluminum wire is no exception. Any conductor can carry the required current. However, exceeding the wire’s (aluminum) capacity causes the conductor to overheat.

These amperage ratings cannot withstand conduction levels exceeding the wire’s recommended current value. Therefore, it’s easy to understand why most contractors prefer copper wire, as it transmits more power than aluminum wire without causing fires.

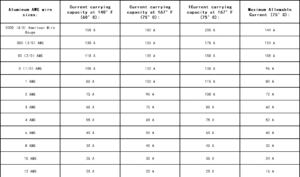

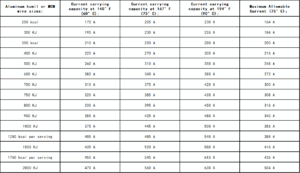

Aluminum Wire Current Rating Chart

Aluminum Wire Current Rating Comparison Chart

This aluminum wire current rating chart clearly displays the current-carrying capacity of aluminum wire across three distinct temperature ranges: 140°F (60°C), 167°F (75°C), and 194°F (90°C).

Additionally, the chart indicates the maximum current aluminum wire can safely carry at an average temperature of 75°C. Note that this value already incorporates NEC code requirements. For example, 6 AWG aluminum wire has a rated capacity of 50 amperes, while NEC stipulates that circuit loads must not exceed 80% of the rated capacity. This means 6 AWG aluminum wire can safely carry 40 amperes or less.

Table 1: American Wire Gauge Aluminum Wire Current Carrying Capacity Chart

Figure 2: Aluminum Wire Current Carrying Capacity Chart by Kcmil

These are thicker wires with a current-carrying capacity up to 560A.

Why use copper instead of aluminum as conductors in power cables?

Reasons to use copper over aluminum as power cable conductors include:

- Copper has a lower thermal expansion coefficient, reducing the risk of damage to connections from destructive forces.

- Copper corrosion is not an issue due to its resistance to most organic chemicals. It also operates reliably over extended periods in most industrial environments.

- As mentioned earlier, copper exhibits excellent creep resistance, which is crucial for avoiding relaxation at contact pressure points and handling components with complex geometries.

- Copper ranks among the most easily weldable metals. When combined with its electrical conductivity, this makes it ideal for applications requiring robust joint integrity.

- Since copper does not react with water, you need not worry about issues like accidental damage from liquid ingress into cables during transport. Conversely, aluminum reacts with water to produce nitrogen gas, which can be hazardous in certain situations.

Conclusion

Conductor material is one variable affecting a wire’s current rating. However, this does not mean you should fill your home or office with copper wiring, especially considering its high cost.

That said, many homeowners can still afford to use copper wire for various small projects. For large-scale projects requiring miles of cable, aluminum wire remains the optimal choice.

Finally, we all know aluminum wire carries less current. Fortunately, you can address this by increasing the wire gauge. Additionally, aluminum wire is lighter and easier to install. Contact JinHai for the best service on all your aluminum wire needs.

Contact us immediately to learn how we can meet your cable and harness requirements. Follow us on Youtube .