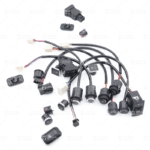

What is a pigtail connector?

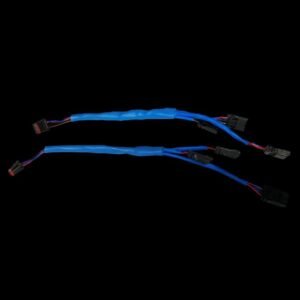

A pigtail connector is a wire assembly featuring a pre-installed connector interface at one end and a bare wire at the other. During use, the bare wire must be connected to the main cable via crimping, soldering, or similar methods.

Its primary function is to efficiently repair or extend wiring harnesses through non-destructive connection methods.

Why use pigtail connector?

Secure Connection: Enhances connection integrity, ensuring safe wiring and reducing electrical system risks.

Installation Efficiency: Eliminates steps like wire stripping and crimping terminals, saving up to 40% installation time.

Signal Stability: Supports high-frequency signal transmission with strong anti-interference capabilities and minimizes signal attenuation.

Maintenance Convenience: Widely applicable for wire extensions and circuit splicing, enabling rapid, non-destructive connections.

Types of Pigtail Connector

Classified by Electrical Characteristics

- Power Type: Features silver-plated terminals for low resistance and superior conductivity, suitable for high-current transmission.

- Signal Type: Ensures stable data signal transmission with strong anti-interference performance.

- Hybrid Type: Simultaneously transmits both power and signals.

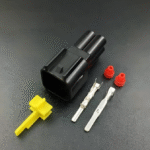

Classified by Structural Features

| Type | Features | Application Scenarios |

| Circular Connector | IP67 or higher protection rating, vibration-resistant | Automotive engine compartments, industrial outdoor equipment |

| Rectangular Connector | High-density pin arrangement, up to 150 pins | Industrial Controllers, Body Control Modules |

| Micro Connectors | Pitch: 0.5mm–1.0mm, ultra-miniature | In-vehicle cameras and sensors |

| Fiber optic pigtail | Transmit optical signals with low loss | In-vehicle entertainment systems, Industrial Ethernet |

Classified by Industry Standards

- Automotive Grade: Complies with USCAR-2 and QC/T 1067 standards, with a temperature range of -40°C to 125°C

- Industrial Grade: Complies with IEC 61076 and UL certification, featuring oil resistance and corrosion resistance

- Military Grade: Complies with MIL-DTL-38999 standards, offering harsh environment tolerance

Selecting the Appropriate Pigtail Connector

To choose a suitable pigtail connector that meets your application requirements, consider the following factors:

- Current Carrying Capacity: Select wire gauge matching the load current, adhering to the current-to-wire cross-section relationship specified in ISO 6722.

- Voltage Rating: Must meet automotive electrical system high-voltage demands, capable of withstanding 600V or 1000V.

- Mechanical Life: Must exceed 500 mating cycles (Automotive applications require a minimum of 50 cycles)

- Temperature Range: Automotive systems require operation between -40°C and 125°C; industrial environments require -25°C to 85°C.

- Vibration Resistance: Must pass vibration testing per ISO 16750-3 standards.

- Sealing Performance: Critical for prolonged exposure in specific environments.

- Cost Considerations: Choose between field crimping or pre-terminated pigtails based on pre-selection

How to Use Pigtail Connector

- Step 1: Turn off power, disconnect battery negative terminal and switch

- Step 2: Strip wires using professional tools, referencing terminal specifications for length

- Step 3: Connect wires securely, ensuring firm connection

- Step 4: Install connector onto terminal device

- Step 5: Test and verify proper connection

Where are pigtail connector used?

- Automotive electronics: Vehicle electrical systems, ADAS systems, infotainment systems

- Industrial control systems: PLC module interconnects, industrial robots

- Energy infrastructure: Charging infrastructure, photovoltaic power generation

- Special applications: Rail transit, aerospace, medical equipment

Frequently Asked Questions (FAQ)

Q1: Are pigtail connectors reusable?

After exceeding the factory-specified mating cycles, contact pressure may decrease. Industrial connectors allow 50 mating cycles, while automotive connectors permit 10-15 cycles.

Q2: How to prevent water ingress into connectors?

Select an appropriate protection rating, use sealing rings correctly, and install silicone gaskets with rubber seals on contact surfaces.

Q3: How to choose connector plating?

- Gold plating: Suitable for high-reliability signal connections

- Silver plating: Suitable for high-current connections

- Tin plating: General-purpose connection method

Summary

Pigtail connectors are critical for electrical system stability. This guide covers selection, installation, and troubleshooting for pigtail connectors.

We hope this information helps you maintain stable and reliable operation in your electrical systems when using pigtail connectors.

Contact us immediately to learn how we can meet your cable and harness requirements. Follow us on Youtube .