New Requirements for New Energy Vehicle Custom Automotive Connectors

- مركبات الطاقة الجديدة: High Voltage Demands

- New energy vehicle powertrains operate at voltages up to 800V, necessitating high-voltage wiring harness connectors. These connectors feature high voltage resistance and strong electromagnetic shielding.

- Intelligent Connectivity: Rapid Data Transmission

- Advanced driver assistance systems require automotive connectors with stable signal transmission, high transmission speeds, and robust shielding performance.

- Lightweighting Requirements

- For new energy vehicles, weight reduction is key to extending driving range. Wiring harness connectors must evolve toward lightweight designs while maintaining performance.

Custom Automotive Connectors: Technical Essentials

الموصل performance hinges on design solutions, material selection, and manufacturing processes. When selecting manufacturers, customization capabilities are a critical consideration.

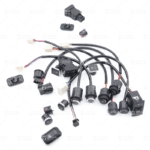

Design Elements of Custom Automotive Connectors

- المحطات الطرفية: Transmit electrical signals.

- Housing: Protective layer for terminals.

- Sealing Ring: Enhances waterproof and dustproof performance.

- Latching Mechanism:

- Primary Latch: Ensures connector engagement with audible confirmation.

- Secondary Locking: Prevents terminals from detaching from the housing due to vibration or cable pulling.

- Misinsertion Prevention and Assist Structures:

- Misinsertion Prevention: Asymmetric shapes ensure correct insertion.

- Insertion/Extraction Assistance: Ensures smooth operation when connectors have numerous pins or high insertion/extraction forces.

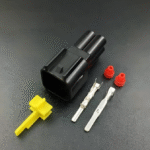

Custom Automotive Connectors Material Selection

Provides critical assurance for electrical connections during operation.

- Housing Material: Premium ABS plastic offering high-temperature resistance, corrosion resistance, and flame retardancy.

- Terminal Material: Copper alloy providing excellent conductivity and cost efficiency.

- Plating Material: Electroplated terminals deliver low resistance, oxidation resistance, and corrosion protection.

Custom Automotive Connectors Testing Standards

Connector failures are the most common failure issues, requiring rigorous testing to meet global certification standards.

- Electrical:

- Contact Resistance: Evaluates terminal connection quality.

- Insulation Resistance: Assesses insulation material performance.

- Withstand Voltage: Measures the connector’s voltage-carrying capacity.

- Physical:

- Insertion/Extraction Force: Ensures reliable connection.

- Terminal Retention Force: Force required to pull out terminals, preventing pin disengagement.

- مقاومة الاهتزازات: Maintains stable connection under automotive road vibrations.

- دورات التزاوج: Maximum number of insertions/removals under operational conditions.

- Environmental:

- Temperature cycling: Simulates temperature variations in operational environments.

- Salt spray test: Evaluates corrosion resistance in humid, saline conditions.

- Ingress protection rating: Verifies dust and water sealing performance.

- Chemical resistance: Withstands chemical agent corrosion.

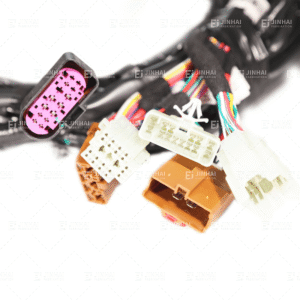

جينهاي Professional Customization Process: From Design to Delivery

JinHai is a professional solutions provider with years of industry expertise, deeply understanding client needs in every project. JinHai maintains a closed-loop process from design to delivery, ensuring high-quality solutions for customers.

- Step 1: In-depth Requirement Communication and Analysis

- Our engineering team thoroughly discusses key factors including application scenarios, electrical loads, environmental constraints, driver cost targets, and project timelines.

- Step 2: Solution Design and Component Selection

- Design solutions based on requirements, including preliminary selection of connector types, terminal specifications, cable materials, and protection ratings.

- Step 3: 3D Modeling and Simulation Validation

- Utilize CAD/CAE software for 3D modeling and virtual assembly, performing simulation analysis on critical performance metrics to identify and resolve potential issues before prototyping.

- Step 4: Prototype Fabrication and Testing

- Rapidly produce functional prototypes and subject them to comprehensive electrical, mechanical, and environmental testing in our ISO/TS 16949-certified in-house laboratory to ensure 100% compliance with design specifications and industry standards.

- Step 5: Automated Mass Production and Quality Control

- Proceed to batch production upon prototype validation. We possess automated capabilities for wire cutting, terminal crimping, assembly, and 100% electrical continuity testing, supplemented by visual inspection systems and pull-out tests.

- Step 6: Delivery and Full-Cycle Technical Support

- We offer flexible global logistics solutions and commit to providing continuous technical support and rapid response services throughout the product’s entire lifecycle.

JinHai: Your Trusted Custom Wire Harness and Connector Manufacturer

An outstanding manufacturer should possess the following attributes:

- Industry Certification Standards: ISO 9001, UL, RoHS, and other certifications.

- R&D and Testing Capabilities: Independent design team, mold development expertise, and fully equipped in-house laboratory.

- Automation Level: Automated processes ensure consistent product quality and stability.

- Project Experience & Success Stories: Proven track record in cutting-edge fields like new energy and autonomous driving.

- Supply Chain & Rapid Response: Partners with stable raw material supply and swift customer response mechanisms.

الخاتمة

جينهاي is dedicated to being a trusted global manufacturer of customized wire harness solutions. We not only possess advanced manufacturing equipment and rigorous production/process workflows but also strictly adhere to IATF16949 و ISO9001 أنظمة إدارة الجودة.

Choose JinHai to accelerate your project’s success—JinHai grows alongside your projects!