As a quality expert with 11 years of experience in quality management, I will analyze the principles and solutions for terminal pin withdrawal from three perspectives.

What is Terminal Backout?

Terminal Backout refers to the abnormal separation of terminals from the housing after connector assembly, resulting in connector failure.

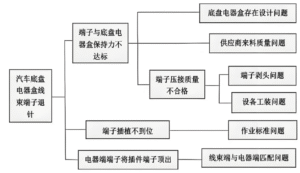

Three Common Causes of Terminal Backout

This failure mode typically arises from three factors:

- ① Insufficient retention force of terminals within the housing;

- ② Mating interference;

- ③ Product application issues.

Terminal Backout (Figure 2) is a relatively common failure mode in wiring harnesses.

Terminal Backout refers to the failure of terminals to reach their intended positions, resulting in connector malfunction. Automotive wiring harnesses primarily rely on manual operations, making quality control challenging. To better prevent and manage terminal pin retraction issues, control measures are implemented across the following key areas: design selection, process protection, terminal crimping, assembly, electrical testing, and final installation.

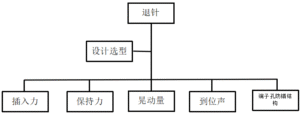

Terminal Backout : Design Selection

Quality is designed and manufactured, not inspected. To prevent Terminal Backout, the first step is design selection. Five key evaluation metrics are listed below (Figure 3).

Insertion Force (Figure 3):

This indicates the ease of terminal assembly. Lower resistance during pre-assembly into connectors facilitates proper seating. Thus, insertion force is the primary selection criterion—lower force reduces assembly difficulty and minimizes terminal dislodgement risk.

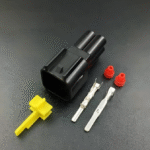

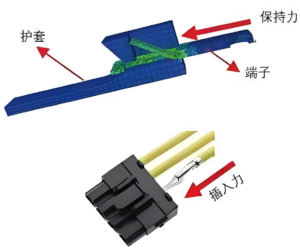

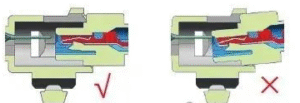

Retention Force (Figure 4):

The horizontal pull-out force of the terminal from the housing (i.e., retention force). A higher retention force makes it less likely for the terminal to be dislodged during connector mating. When selecting designs, opt for connectors and terminals with greater retention force.

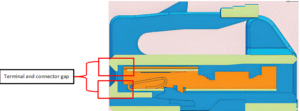

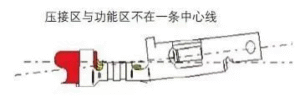

Play (Figure 5):

When mating male and female connectors, significant terminal play within the housing can cause terminals to be pushed out. To reduce the risk of pins being dislodged during mating, prioritize selecting terminals and connectors from the same manufacturer during design selection (purpose: to ensure minimal terminal play when the connector and terminal are matched).

Positioning Sound:

The audible confirmation when terminals are fully seated during assembly. Currently, terminal pre-installation relies entirely on manual labor, posing a risk of terminal pins slipping out. To help employees better identify proper pre-installation seating, we introduce a performance metric: the positioning sound. This assembly confirmation sound must exceed ambient noise levels (which should range between 30dB-50dB): 7dB above ambient before moisture exposure, 5dB above after moisture exposure, or as mutually agreed upon by both parties.

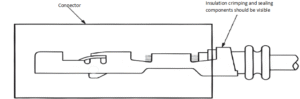

Terminal Hole Misinsertion Prevention Structure (Figure 6):

When inserted in the wrong orientation, the terminal must not enter the terminal hole, and the insulating support and sealing components must remain exposed outside the terminal hole. During troubleshooting, we observed that some terminals could still be inserted into the connector when misaligned, making it difficult to detect during retraction. Therefore, during design selection, the ease of misaligned insertion must be considered to ensure terminals cannot be fully seated when assembled incorrectly.

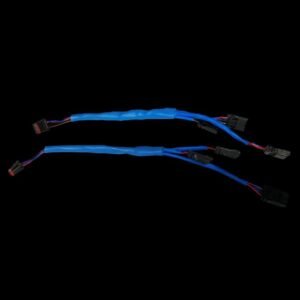

Process Protection

Two factors contribute to terminal pin retraction: spring sheet deformation and terminal misalignment.

Both result from external forces during processing causing terminal deformation. To protect terminal spring sheets from deformation due to external forces, protective caps (Figure 7) must cover terminal heads after crimping. These caps should only be removed during assembly. After harness assembly is complete, seal the male connector housing with sealing tape or a non-woven fabric bag (Figure 8) to prevent terminals from becoming misaligned due to external impacts during transportation.

端子圧着

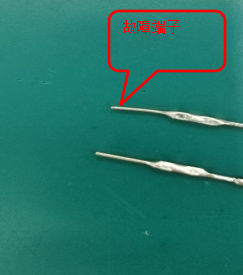

Terminal crimping is a critical step in automotive wiring harness production. The primary process involves connecting electrical systems to terminals using fully automated crimping equipment to integrate terminals with circuits. Terminal crimping is also a contributing factor to terminal pin retraction during harness manufacturing. “Banana-shaped” terminals are a common issue arising from excessive bending during crimping, typically caused by crimping die problems (Figure 9). During assembly, terminal crimping deformation can result in increased insertion/extraction force for connectors in mild cases. In severe instances, male terminals may fail to engage the effective area of female terminals, causing terminal disengagement. Adjusting the limit pins on the crimping equipment can resolve such issues.

Case Study: The final assembly workshop reported terminal pins retracting during AC socket insertion for a specific vehicle model. Two terminal states were observed. Comparison revealed that faulty terminals exhibited a banana-shaped deformation. Testing confirmed that straightening the defective terminals eliminated pin retraction during insertion. Subsequently, adjusting the crimping equipment’s limit pin resolved the issue completely.

Assembly

Wire harness assembly primarily relies on manual labor. To better mitigate the risk of improper terminal assembly, the industry generally follows the “one insert, two listen, three pull back” procedure.

Insert refers to inserting the terminal,

Listen refers to hearing the sound confirming proper insertion,

Pull refers to gently tugging the terminal after insertion to check for dislodgement.

With workers inserting terminals thousands of times daily, operational fatigue is common. To help employees develop muscle memory, we implemented adjustments: First, “pull once” before each shift and during breaks. Here, “pull” means using a pull tester installed at the workstation. Before shifts and after breaks, employees must manually pull the force gauge to ensure the insertion force becomes muscle memory. Second, we changed the sequence to “Look, Insert, Listen, Pull Back.” Adding “Look” helps identify terminal deformation and ensures banana terminals are inserted in the correct orientation.

電気試験

ワイヤーハーネスの電気テストは、ハーネス製造の重要な段階です。端子のズレや端子ピンの抜けを効果的に検出・防止するために、電気検査装置は以下の条件を満たす必要があります:

第一に、オス端子固定具は、ずれた端子が接触するのを防ぐために、(図12に示すような)位置ずれ防止グリッドを備えていなければならない。第二に、電気試験プローブは、試験中に端子が押し出されるのを防ぐために、ねじ式の段付きピンを使用しなければならない。第三に、寸法チェーンに基づいてシース内での端子の動きを計算してプローブを製作し、プローブの定期的なメンテナンススケジュールを確立すること。.

Case Study:A作業所から、特定車種の左フロントドアコントロールパネルのコネクタの取付けが困難(端子が飛び出す)との報告があった。現場を調査したところ、当該車種はB作業所からA作業所に移管されて組み付けられていたことが確認された。組み立ての際、位置合わせが不適切なため、メス端子が押し出された。組み付け時に適切なアライメントを確保することで問題は解決した。この事例は、ワイヤーハーネスを組み立てる際、従業員は挿入時にコネクタのオスとメスのスリーブが正しく位置合わせされていることを確認しなければならない(図13)ことを明確に示している。この習慣により、組立工程中の位置ズレにより端子が押し出されるリスクを低減することができる。.

本稿では、自動車用ワイヤーハーネスにおける端子ピン抜けに影響を及ぼす要因について詳細に分析する。設計の選択、ハーネス製造、工程保護、組立技術にわたる具体的な予防策と管理策を探求している。この研究は、ハーネス設計選択の指針を提供し、製造工程管理の具体的な推奨事項を提示し、故障モード解析の具体的な方法論を提示する。.

お問い合わせ お客様のケーブルとハーネスのご要望にどのようにお応えできるか、今すぐお問い合わせください。フォローしてください Youtube .