Automotive Wiring Harnesses Connectors Failures and Solutions

Automotive Wiring Harnesses Connectors Poor Contact

- Symptoms: Intermittent wiring harness signals, flickering lights, etc., in the electrical system.

- Causes:

- Terminal oxidation, corrosion, or contamination.

- Loose or deformed connector pins/sockets.

- Micro-motion wear on terminals due to prolonged vibration.

- Solutions:

- ○Clean terminals with electronic cleaner spray and dry thoroughly.

- ○Verify terminal seating; re-crimp with specialized tools or replace connectors as needed.

- ○Secure connections post-mating with appropriate retaining clips or cable ties.

自動車 ワイヤーハーネス コネクター Short Circuits

- Symptoms: Blown fuses, overheating wiring harnesses.

- Causes:

- Damaged insulation causing conductor contact shorts.

- Water ingress inside the connector causing a short circuit.

- External compression or abrasion exposing wires.

- Solutions:

- Inspect the wiring harness for exposed insulation and add protective sheathing or re-wrap.

- Replace damaged wire sections to restore insulation.

Automotive Wiring Harnesses Connectors Open Circuit

- Symptoms: No response from electrical system connections.

- Causes:

- Internal wire breakage due to excessive bending, vibration, or aging.

- Terminal pins loosened.

- Connector not fully seated or latch failure.

- Solutions: Locate break points segment by segment using a multimeter continuity test.

- Verify internal terminals are fully inserted and confirm retention force with a “one-pull” test.

- Recrimp or replace broken wires/terminals.

Automotive Wiring Harnesses Connectors Insulation Damage

- Symptoms: Current leakage, intermittent system failures, abnormal grounding.

- Causes: Insulation aging/cracking due to high temperatures, oil contamination, or chemicals.

- Mechanical friction, animal bites.

- Solution: Visually inspect harness outer sheath for cracks, hardening, or damage.

- Apply insulating tape for localized repairs; replace entire harness segment if severe.

- Add corrugated tubing or braided sleeves to high-wear areas.

Automotive Wiring Harnesses Connectors Terminal Corrosion/Oxidation

- Symptoms: Increased contact resistance, insufficient power supply to equipment.

- Causes:

- Moisture ingress (e.g., water vapor, salt spray) into connectors.

- Aged or damaged connector seals.

- Solutions:

- Disassemble connectors and gently clean terminal surfaces with fine sandpaper or cleaning agents.

- Replace seals and ensure waterproof caps are securely fastened after reassembly.

- In humid environments, use gold-plated terminals or apply conductive anti-corrosion grease.

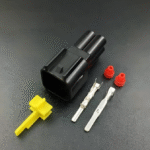

Automotive Wiring Harnesses Connectors Damage

- Symptoms: Cracked plug housing, broken latches, bent pins.

- Causes:

- Excessive force or improper tools during installation/removal.

- Connector aging due to high temperatures in the engine compartment.

- Solutions:

- Replace damaged housing or connector.

- Insert/remove connectors in the correct direction without excessive force.

- Use connectors made of heat-resistant materials in high-temperature environments.

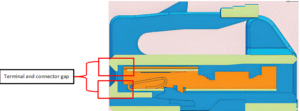

Automotive Wiring Harnesses Connectors : Terminal Dislodgement

- Symptom: Circuit interruption despite intact wiring harness appearance.

- Cause: Insecure terminal crimping or terminal pushed back during mating.

- Secondary locking mechanism failed to engage.

- Solution: Use a probe or microscope to verify terminal seating.

- Recrimp ensuring audible “click” confirmation and validate with pull-back test.

- Inspect integrity of connector secondary locking mechanism.

Preventive Measures for Automotive Wiring Harnesses Connectors

Basic Testing

- Insertion/Extraction Force: Test connector insertion/extraction force, standard range 10–50N.

- Visual Inspection: Check insulation aging, seal deformation, monitor harness displacement.

- Electrical Testing: Multimeter resistance measurement: >0.5Ω indicates poor contact.

- Vibration Testing: Monitor instrument signal changes while shaking the connector.

Professional Inspection

- Oscilloscope Analysis: Capture CAN bus signal distortion to diagnose intermittent faults.

- Retractable Probe: Check terminal voltage without disconnecting the connector.

- Infrared Thermal Imaging: Locate abnormal hot spots.

結論

Automotive wiring harness connector failures result from a complex interplay of electrical, mechanical, and environmental factors.

ジンハイ は、カスタマイズされたワイヤーハーネスソリューションを専門とするグローバルメーカーです。先進的な製造設備と厳格な生産/プロセスプロトコルを有し、以下を厳守しています。 IATF16949 そして ISO9001 品質管理システム。.

プロジェクトの成功を加速させるためにJinHaiをお選びください。ジンハイはお客様のプロジェクトと共に成長します!