Lighting Harness and Components

JinHai is a premium lighting harness manufacturer serving the automotive, architectural, industrial, residential, and outdoor sectors. Our harnesses utilize specialized high-quality materials tailored to each application, ensuring reliable performance.

アメージング クライアント

Different vehicles utilize distinct lighting systems, such as headlights, turn signals, brake lights, and ambient lighting. Similarly, wiring harnesses are required for road, residential, tunnel, and medical lighting applications. All lighting systems require precise wiring harness connections to ensure the reliable operation of LED lights, halogen bulbs, and other types of lighting fixtures. As a professional wiring harness manufacturer, JinHai leverages its robust manufacturing expertise and stringent quality control to design, manufacture, and assemble lighting harnesses for these diverse applications.

Lighting Applications

JinHai can produce lighting harnesses for the following fields:

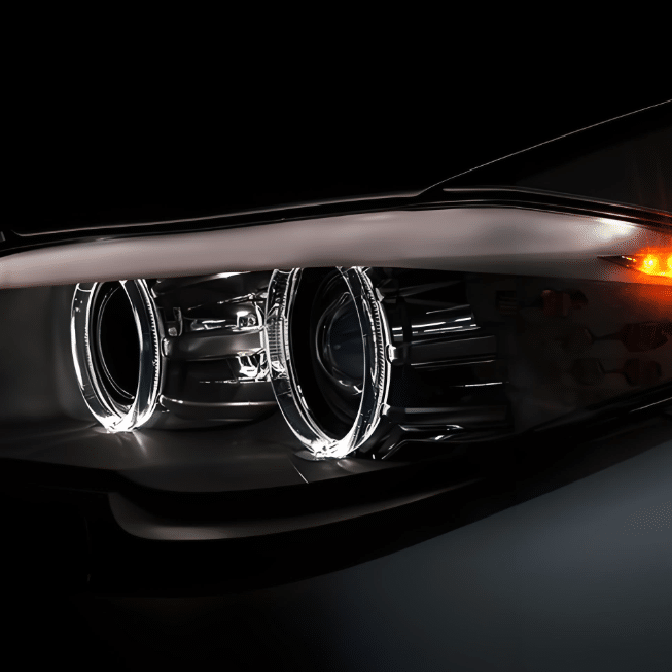

Vehicle Lighting System

In vehicle lighting systems, relays serve as critical protective switches. Lighting harnesses must be equipped with connectors compatible with such electronic components to withstand harsh external environments.

Medical Surgical Lighting

Surgical lights are the most common lighting fixtures in medical surgical settings, categorized into mobile, wall-mounted, and ceiling-mounted types. As a type of cold light source, surgical lights should emit minimal heat while maintaining sufficient depth of field and accurate color rendering. Therefore, overheat protection and voltage spike protection are core safety features.

Road/Outdoor

Exposed wiring harnesses installed outdoors must possess robust core functionality. Insulation layers and connectors must be sufficiently sturdy and hermetically sealed to withstand environmental conditions such as UV radiation, rainfall, and extreme temperatures. Simultaneously, they should maintain adequate flexibility and incorporate safety devices like fuses or relays to prevent short circuits or overloads.

Products we Produce

Customize your Exclusive Project

A wide variety of lighting harnesses with varying requirements. However, our robust design and manufacturing capabilities ensure the smooth success of your project.

品質と安全性、, 保証

Our agricultural machinery wiring harness assemblies are certified to ISO 9001:2015 and ITAR standards, meeting the highest global quality benchmarks, including those of the United States and Canada.

お客様の声

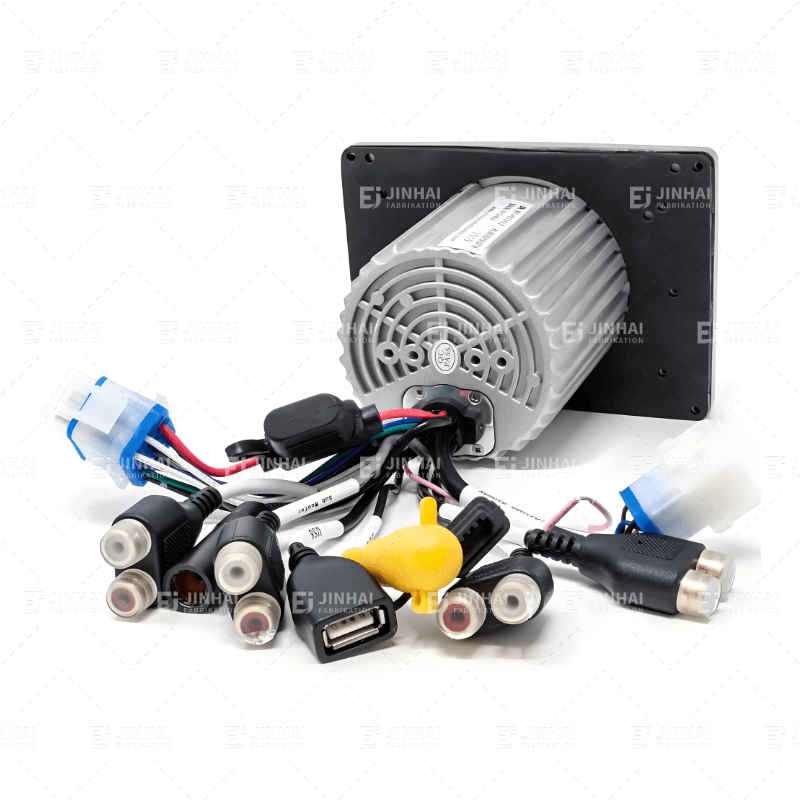

What components make up a custom lighting harness?

Lighting harnesses vary depending on their application environment. For example, lighting harnesses used in office buildings typically feature exposed wiring without overly complex connectors or safety devices.

In contrast, automotive lighting harnesses generally consist of terminals, connectors, coverings, and fasteners.

What are the benefits of lighting harnesses?

Easy installation, plug-and-play.

Enhanced safety and reliability, while reducing labor costs for installation.

Which of the following factors may damage wiring harnesses?

High temperatures, temperatures below freezing, and prolonged exposure to humid environments can all cause damage to wiring harnesses.

What are some examples of electrical faults?

Electrocution or sparks. Sparks appearing around outlets or appliance switches, or experiencing a tingling sensation during use, are clear signs of electrical faults—or at least indicate a malfunctioning appliance.

What impact does damaged insulation have on wiring harnesses?

Insulation failure can lead to equipment malfunctions, electrical damage, and even endanger personal safety. The importance of insulation cannot be overlooked. In many applications, the insulation layer serves as the first line of defense in protecting against electric shock.