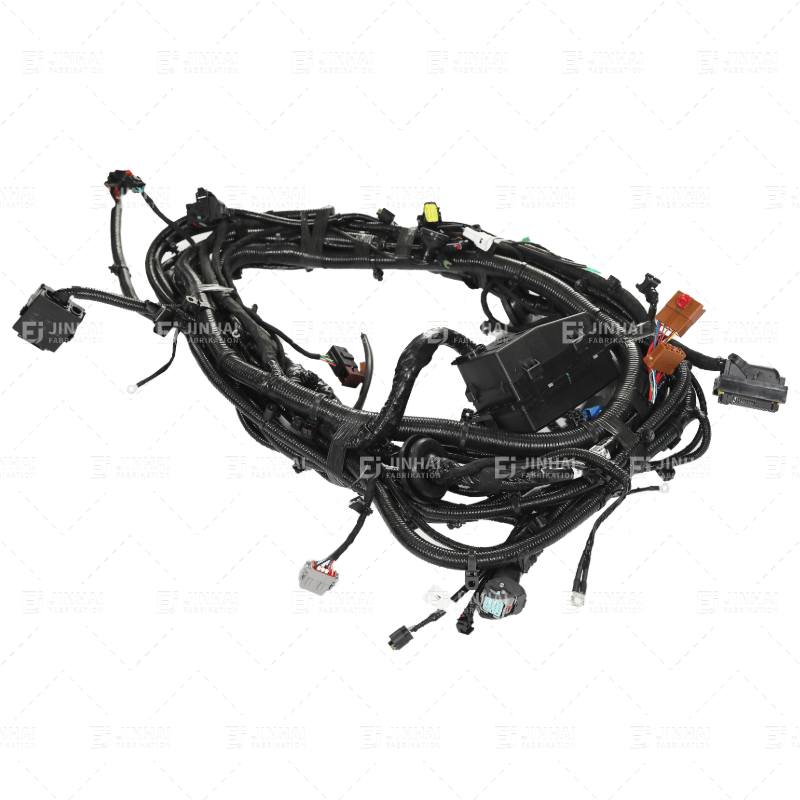

Instrument Wiring Harness Intorduce

Understand the five major advantages of instrument wiring harnesses, enhance vehicle safety, and choose high-quality Instrument Wiring Harness.

Instrument Wiring Harness In line with industry trends

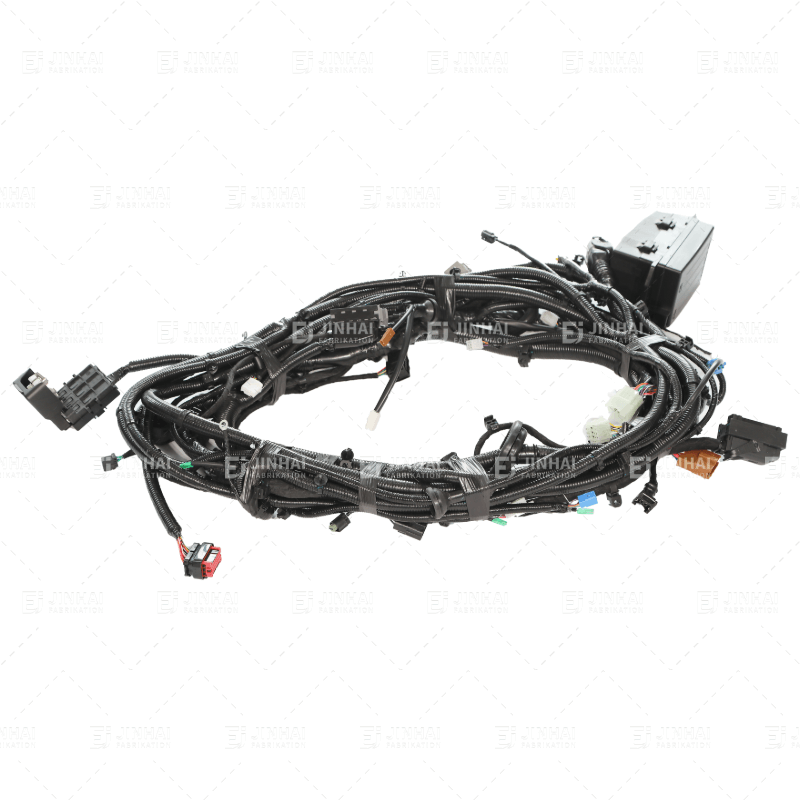

- Aluminum conductors replace copper wires: Using ultrasonic welding technology, 95mm² of aluminum conductors have the same current-carrying capacity as 70mm² of copper wire, while reducing weight by 21%

- Integration: The instrument cluster, HUD, and central control panel are combined into a “cockpit-domain wiring harness,” reducing the number of wiring harness controllers and harness complexity

- Intelligent diagnosis: Implanted current sensors monitor wiring harness degradation in real time with over 98% accuracy

- Evolved safety redundancy: A dual-processor architecture uses MCUs to cross-check signals to avoid single points of failure

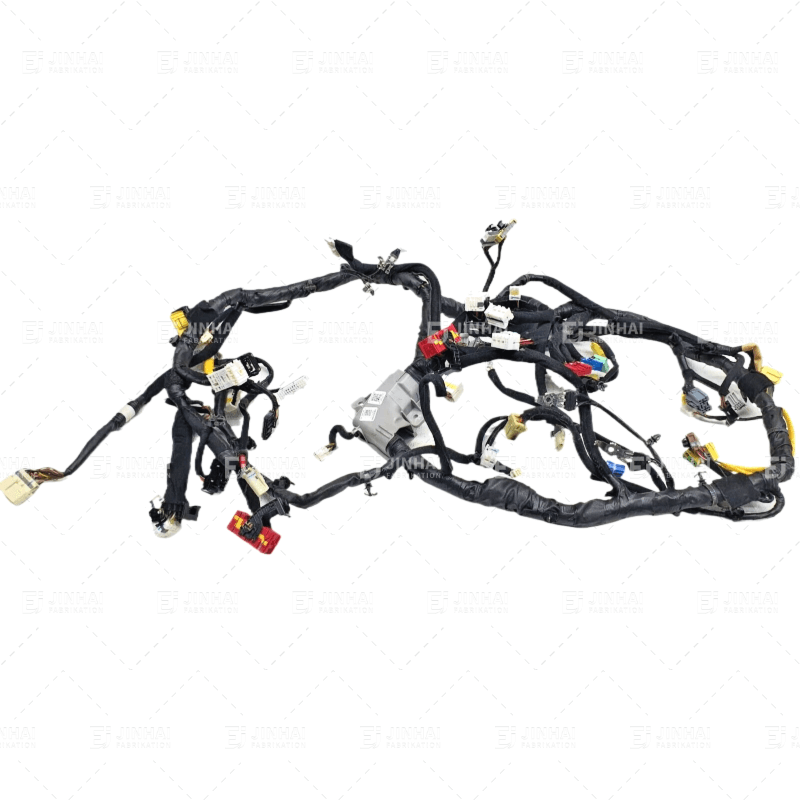

Instrument Wiring Harness Communication Standards

CAN 2.0 Protocol:

- CAN 2.0A: 11-bit identifier, suitable for low-speed communication (such as instrument indicator light control).

- CAN 2.0B: 29-bit identifier, supports high-speed communication (such as real-time vehicle speed transmission), with a rate of up to 1Mbps.

- Physical Layer Requirements: The differential voltage (V_diff) must be stable between 0.9V and 5V to ensure anti-interference performance; twisted-pair impedance matching suppresses common-mode noise.

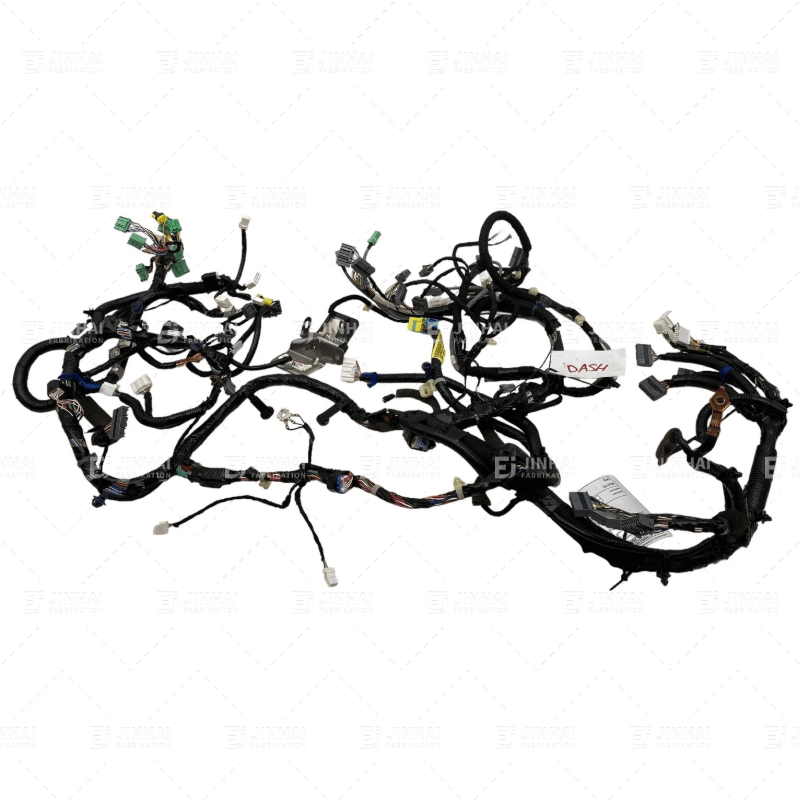

The impact of instrument panel wiring harness design on engine performance optimization

- ECU communication accuracy: Excessive resistance caused by wiring harness inaccuracy can cause sensor transmission attenuation (such as oxygen sensor voltage deviation), affecting air-fuel ratio calculations and significantly reducing fuel efficiency

- Lightweighting: Aluminum wiring (ultrasonic welding, 40% weight reduction) reduces engine overload and effectively reduces fuel consumption by 0.3L/100km.

お問い合わせ お客様のケーブルとハーネスのご要望にどのようにお応えできるか、今すぐお問い合わせください。フォローしてください Youtube .