What is the Starter System?

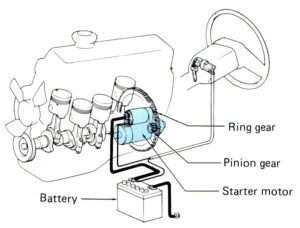

The automotive starter system is the core function that uses the battery to power the engine, primarily consisting of several key components:

- Battery: The high current needed to start the engine comes from the vehicle’s battery.

- Ignition Switch: Turning the ignition switch to the start position directs current to the starter solenoid.

- Starter Relay: The starter relay controls the flow of current to the starter motor.

- Starter Motor: The vehicle’s starter motor is the foundation for engine startup.

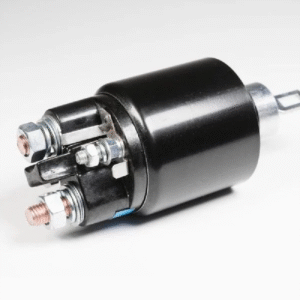

- Starter Solenoid: Connects the circuit between the starter motor and the battery power source.

How does the starting system operate?

The entire starting process begins the moment you press the start button:

- Start Signal: After turning the ignition switch, a small current flows from the battery through the ignition switch and the starter solenoid’s control coil.

- Starter Solenoid: Activates the solenoid’s internal electromagnet, generating a powerful magnetic field that precisely engages with the engine’s flywheel ring gear.

- Motor Rotation: Battery current flows to the starter motor, driving it to spin rapidly and turn the engine flywheel, thereby completing the engine start process.

Note: The starting system can only be initiated when the vehicle is in neutral or park gear.

When should the starter solenoid be replaced?

When the starting system malfunctions, the vehicle exhibits distinct failure symptoms.

- No Response: When turning the key, the dashboard lights illuminate but no starting sound is heard, and the engine shows no response.

- Single audible feedback: Attempting to start produces only a loud “click” sound, but the starter motor does not rotate.

- Continuous rapid sound feedback: A series of rapid “clicks” is heard during starting, typically indicating low battery charge or poor solenoid contact.

- Slow and Weak Starting: The starter motor turns very slowly, struggling to crank the engine.

- Shrill Noise: A high-pitched sound during starting, usually caused by the starter motor’s drive gear failing to engage properly with the flywheel.

- Burning Smell or Smoke: A burnt odor or smoke emanating from the engine compartment, indicating a short circuit in the electrical system or overheating of the starter motor.

Importance of the Starter Solenoid Valve

The solenoid valve is a critical component in the automotive starting system. Its significance manifests in two key aspects:

- Relay Function: The solenoid valve uses a small electrical signal to control the flow of a larger current circuit, effectively protecting components like the ignition switch from damage and ensuring driving safety.

- Mechanical Actuator: The solenoid valve efficiently activates the starter motor, ensuring power transmission.

Primary Symptoms of Starter Solenoid Valve Failure

While starting system issues can manifest in various ways, certain symptoms specifically indicate starter solenoid valve problems.

The primary symptom is no engine response after turning the ignition key.

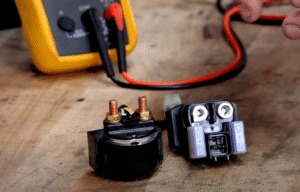

The most common diagnostic method involves using a multimeter to test the voltage between the terminals. If no current is detected, it indicates a solenoid valve malfunction.

How to Replace the Starter Solenoid Valve

Solenoid valve repair is not difficult. After confirming the solenoid valve is faulty, replacing the starter requires only the following steps:

- Safety Preparation: Disconnect the negative battery cable to prevent accidents.

- Locate and Remove: Identify the starter solenoid, typically mounted inside the starter or on the engine compartment side.

- Mark and Disconnect Wiring: Photograph or clearly label each wire’s position before disconnecting all connections. Disconnect the ignition wire and unscrew all mounting bolts.

- Remove Solenoid Valve: Unscrew the mounting screws securing the solenoid valve.

- Install New Valve: Reinstall the new solenoid valve in reverse order of removal, ensuring proper seating.

- Test Operation: Reconnect the battery negative cable and test the starter system to verify functionality.

How to Connect the Starter Solenoid Valve?

The starter solenoid valve typically has three terminals:

- B+ Terminal: Power input.

- M Terminal: Motor output.

- S Terminal: Receives start signal.

Key Connection Points for Solenoid Valves:

- Clean Connections: Keep all terminals and cable joints clean.

- Avoid Mixing: Incorrect wiring can cause instantaneous overvoltage damage.

- Secure connections: Tighten all bolts firmly.

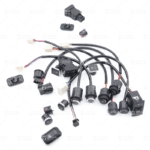

Starter Solenoid Valve Failure: Harness Troubleshooting Methods

If a wiring harness issue is suspected, use these methods to investigate:

- Visual inspection: Carefully examine all harnesses connected to the solenoid valve for signs of wear, corrosion, or aging.

- Battery check: Verify the battery voltage is no less than 2.6 volts.

- Check solenoid valve connection: Ensure the starter connector is securely fastened to prevent malfunction due to loose connections.

- Voltage testing: Use a multimeter to test the solenoid valve’s voltage and continuity.

- Standing voltage test: Ground the multimeter’s black probe and touch the red probe to the B+ terminal. The reading should stabilize around 12V. If no voltage is present, the main cable from the battery to the solenoid valve is faulty.

- Signal Test: Keep black probe grounded. Touch red probe to S terminal while turning ignition switch ON and holding it in the ON position. Normal voltage should be approximately 12V. If no voltage is present, the fault originates in the control circuit.

- Output Test: Turn ignition switch ON and hold it in the ON position. Move red probe from S terminal to M terminal. Normal voltage should be approximately 12V. If no voltage is present, the solenoid valve itself is damaged.

- Ignition Switch Inspection: If both solenoid and starter function correctly, the issue likely lies with the ignition switch.

結論

The starter solenoid is an indispensable component in automotive starting systems.

Understanding its operation, identifying faults, and performing regular maintenance and wiring upkeep are essential for sustained, reliable performance.

ジンハイ is a global manufacturer specializing in customized wiring harnesses and components.We possess advanced manufacturing equipment and stringent production/process protocols, while strictly adhering to IATF16949 そして ISO9001 品質管理システム。.

プロジェクトの成功を加速させるためにJinHaiをお選びください。ジンハイはお客様のプロジェクトと共に成長します!