Custom Military Cable Assembly Manufacturer

JinHai stands as a premier cable assembly manufacturer in China. We deliver precise solutions that meet the stringent requirements of the military sector. Holding ISO 9001 and IATF 16949 certifications, we are committed to providing high-quality and reliable military cable assemblies.

Nuestra Clientes

JinHai stands as China’s premier manufacturer of cable assemblies.

We specialize in military-grade cable assemblies for applications in vehicles, fuses, communication systems, command systems, and other defense installations.

Por qué elegir JinHai ?

Customer Recognition

We provide a wide range of precision solutions for military equipment manufacturers, security forces, and irregular forces worldwide, earning consistent acclaim.

Short Lead Times

Leveraging robust manufacturing capabilities and localized logistics supply chains, we achieve a 99% on-time shipment rate within 4 weeks of order placement.

Soluciones a medida

We specialize in providing custom-designed military cables and components for military vehicles, communication systems, and other applications.

Servicio individual

From initial design to mass production, we provide dedicated one-on-one service throughout the entire process to ensure all your concerns are effectively addressed.

Multi-industry experience

JinHai boasts over 20 years of industry experience, enabling us to deliver high-quality and precise solutions for medical aesthetics, home furnishings, passenger vehicles, and military facilities.

Reliability

As a premium supplier of military cables for the defense industry, we precisely match raw materials for various cables according to stringent industry requirements. Through meticulous process control capabilities, we produce products that meet IPC/WHMA-A-620 standards and are designed for environmental adaptability.

Process Control Capability

JinHai’s customized solutions meet your specification requirements with superior craftsmanship and technology.

Precision Services

We also provide turnkey solutions encompassing the following:

- Cutting, stripping, and crimping

- Military cables and assemblies

- Comprehensive military connectors

- Precision machining

- Value-added services such as 12-hour response, custom cable coding, visual inspection, and product testing.

Especificaciones técnicas

Our military cables meet the following technical specifications:

- Materials compliant with ISO 9001 and IPC/WHMA-A-620 Class III standards

- Product reliability

- Electromagnetic interference prevention

- Cabling design suitable for compact spaces

- Robust, well-sealed overmolding

- Flexible design meeting military requirements

Connector Type

Based on your requirements, we can utilize connectors from brands such as JAE, TE, HIROSE, and JAE. We also offer premium Chinese connector manufacturers like HL, THB, and ZJZ, ensuring performance while achieving cost reduction objectives.

Fabricación de prototipos

We provide samples for matching and performance testing. Mass production can only commence after the samples are approved as qualified.

Production Principles

Our military cables are custom-manufactured to withstand diverse operational environments:

- Multiple shielding configurations

- Customizable wire gauge, connector types, insulation materials, and colors

- Wires with varying strand counts and conductor numbers

- Custom braided mesh, rubber tubing, heat-shrink tubing, and positioning labels

- Custom Overmolding

Delivered Products

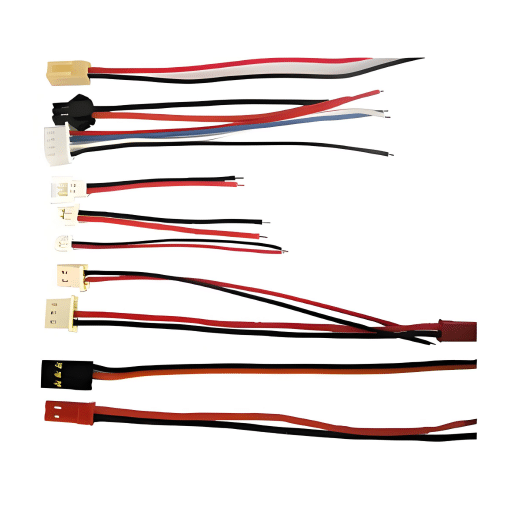

Please explore our diverse range of military cable assemblies.

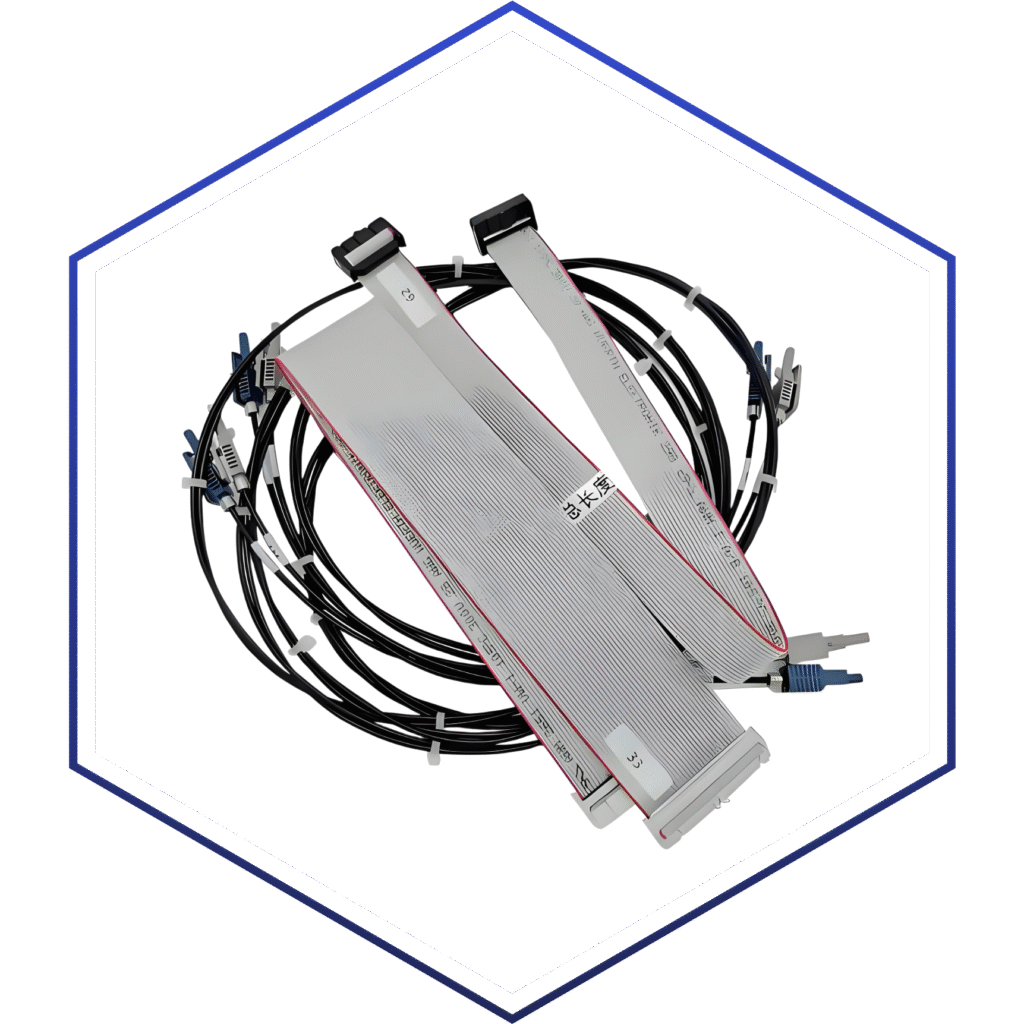

Aviation Cable Assemblies

Offers exceptional reliability, shock resistance, and flexibility in aerospace applications.

Aviation Communication Cable

Lightweight and compact design, exceptional electrical performance, and durability are the core requirements for this wiring harness. Manufactured using world-class equipment and precision process control, it enhances electronic countermeasures between aircraft while freeing up more space in individual soldiers' load-carrying capacity.

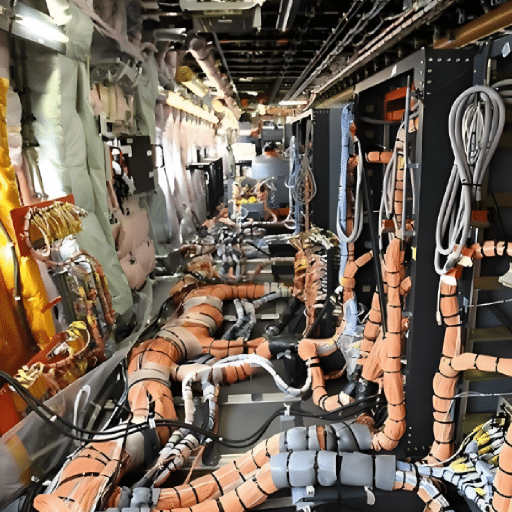

Cable Assembly for Tracked Vehicles

Seismic resistance, dustproofing, and interference immunity are core requirements for tracked vehicles. JinHai employs premium materials and precise process control to ensure this wiring harness meets industry standards and your specific needs.

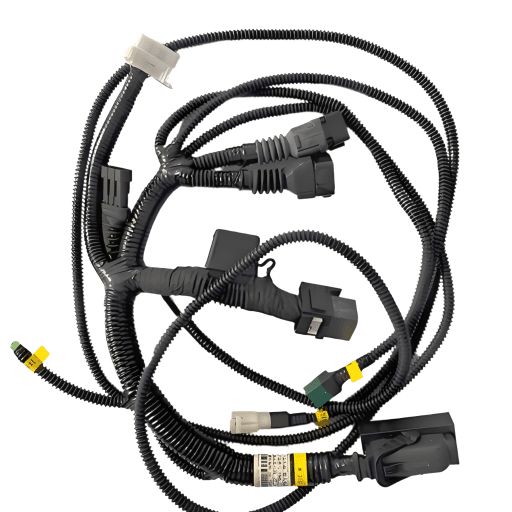

Communication System Cable Assemblies

These cables utilize premium materials, multi-color wiring, and lightweight design to ensure reliable signal transmission while facilitating easy identification and installation.

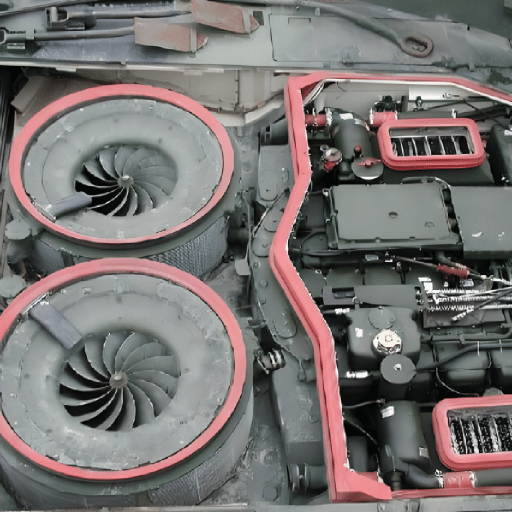

Tank Power System Cable Assembly

This cable features shock-resistant, dustproof, and waterproof design, making it capable of withstanding various outdoor environments with ease.

Drone Battery Cables

The robust, shock-resistant design combined with premium materials ensures this wiring harness delivers stable, reliable power.

Looking for The Best

A medida Mazo de cables &

Cable Assembly Service?

Fast Turnaround Time

At JinHai, we ensure that custom wiring harness solutions are tailored to your needs, with quotations delivered within 12 hours to keep your projects on track.

Certified Quality Assurance

Our factory is ISO9001 and IATF16949 certified, guaranteeing the highest standards of quality, reliability, and compliance for all custom wiring harness and cable assembly services.

One-Stop Custom Solutions

We offer a complete, one-stop solution for all your wiring harness needs, from design to manufacturing, ensuring you get exactly what you need for your project.

Colaboramos con los mejores fabricantes y proveedores

Under its global strategic framework, JinHai can procure high-quality components through specialized channels.

Lo que dicen nuestros clientes

What standards must military wiring harnesses meet?

Military wiring harness layouts must comply with MIL-Spec wire. This is the standard used by the U.S. Department of Defense for manufacturing specialized wires and cables.

How to shield electromagnetic interference in military cables?

Heat-shrink tubing: Utilizes specialized polyolefin heat-shrink tubing to add an additional layer of protection against electromagnetic interference.

Shielded cables: Employ multi-layer and high-coverage shielding technology to block electromagnetic interference.

Do your products comply with MIL-STD 461G standards?

Certainly. We adhere to IPC/WHMA-A-620 requirements throughout the entire process—from material selection to manufacturing—ensuring military equipment is not susceptible to or does not cause unacceptable electromagnetic interference.

What requirements must be met when designing military wiring harnesses?

Military wiring harness design must start with material selection.

Features such as gold-plated terminals, insulation materials like XLPE and PTFE, and shielding methods like braided mesh tubing + aluminum foil wrapping are essential to ensure rugged durability and protection against RF and microwave interference.