Custom Medical Cable Assembly OEM Manufacturer

JinHai is a premium supplier of high-quality medical cable assemblies. We provide tailored solutions precisely aligned with your requirements while meeting the stringent demands of the medical industry. With ISO9001 and IATF16949 certifications, we are committed to delivering reliable, high-quality cable assemblies.

Nuestra Clientes

JinHai, as a leading manufacturer of medical cable assemblies, specializes in producing medical-grade cable assemblies tailored for the healthcare industry.

Our strength lies in designing medical cable assemblies that meet your specific requirements and satisfy OEM manufacturers.

Por qué elegir JinHai ?

JinHai is a company founded on the cornerstones of integrity and quality, committed to ensuring quality, efficiency, and sustainable development.

Customer Satisfaction

We provide diverse precision solutions to medical device manufacturers, hospitals, and clinics worldwide, earning consistent praise from our clients.

Short Lead Times

Leveraging robust manufacturing capabilities and localized logistics supply chains, we achieve a 99% on-time shipment rate within 4 weeks of order placement.

Soluciones a medida

We specialize in providing tailor-made medical cables and components for diagnostic equipment, medical devices, and more.

Dedicated Service

From initial consultation to after-sales support, our dedicated team provides comprehensive one-on-one service throughout the entire process, promptly addressing all your questions and concerns.

Amplia experiencia

With over 20 years of industry expertise, JinHai delivers high-quality and precise solutions.

Safety

As a premium supplier of medical cables in the healthcare industry, we source raw materials for various cables according to stringent industry standards. Leveraging robust manufacturing capabilities, we produce products that meet both industry requirements and your specific needs.

Unrivaled Manufacturing Capabilities

JinHai’s customized solutions meet your specification requirements with superior craftsmanship and technology.

Targeted Services:

We also provide turnkey solutions encompassing the following:

① Cutting, stripping, and crimping

② Medical cables and their components

③ Comprehensive medical connectors

④ Precision machining

⑤ Value-added services such as 12-hour response, custom cable coding, visual inspection, and product testing.

Technical Specifications:

Our medical cables meet the following technical specifications:

① Biocompatible materials compliant with ISO 10993 and US Class VI standards

② Chemical resistance of the product

③ Prevention of electromagnetic interference and radio frequency interference

④ Cabling design suitable for compact spaces

⑤ Robust, well-sealed overmolding

⑥ Ergonomic design

⑦ Flexible design meeting military requirements

Standard Certification

We have achieved certification to TF16949 and ISO9001 standards, ensuring our delivered products meet the industry’s highest requirements.

Connector Types

Based on your requirements, we can utilize connectors from brands such as TE, MOLEX, JST, JAE, and HIROSE. We also offer premium Chinese connector manufacturers like HL, THB, and ZJZ to achieve cost reduction objectives.

Fabricación de prototipos

We can provide samples and prototype samples for your actual matching verification. We will only commence mass production after receiving your prototype approval.

Custom Manufacturing

Our medical cables are custom-manufactured to accommodate diverse application environments:

① Breakout points at any desired location

② Free selection of wire gauge, connector type, insulation material, and color

③ Wires with varying strand counts and conductor numbers

④ Custom braided mesh, rubber tubing, heat-shrink tubing, and positioning labels

⑤ Custom overmolding

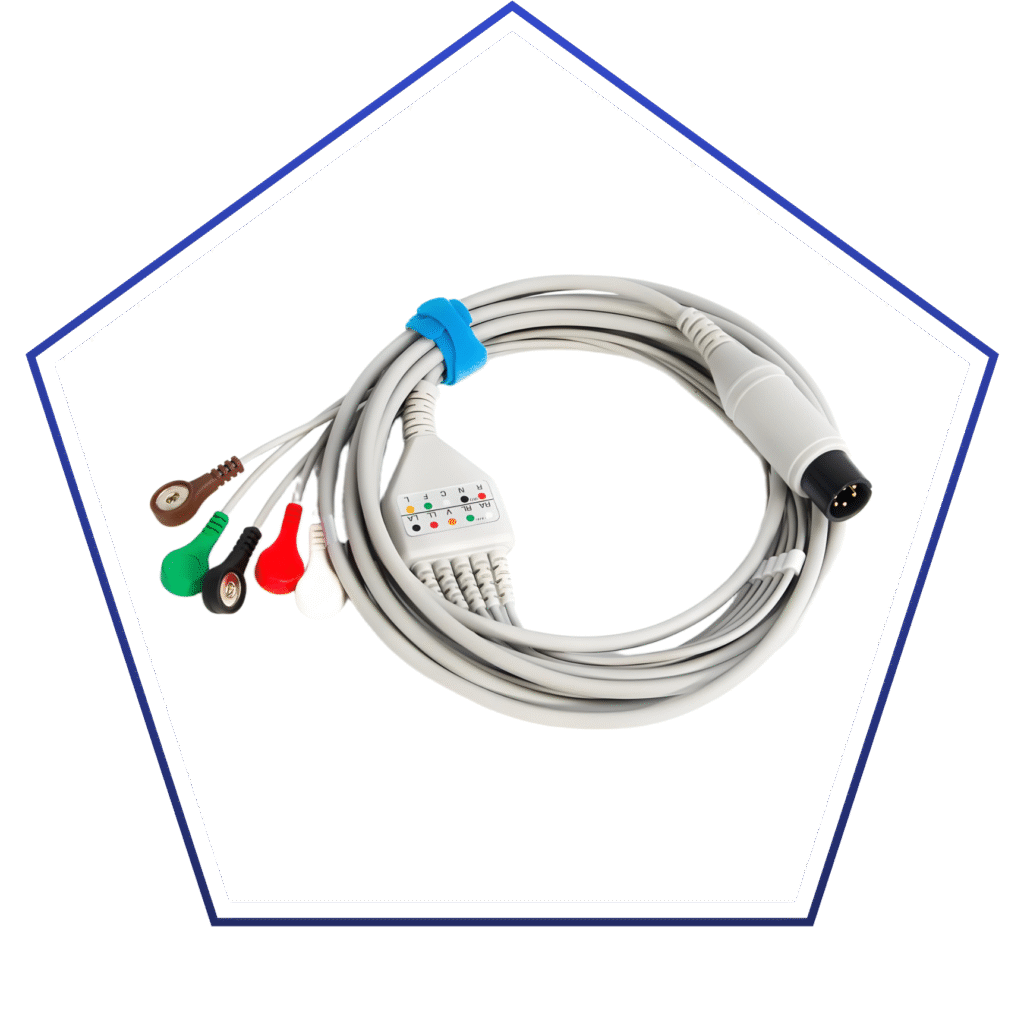

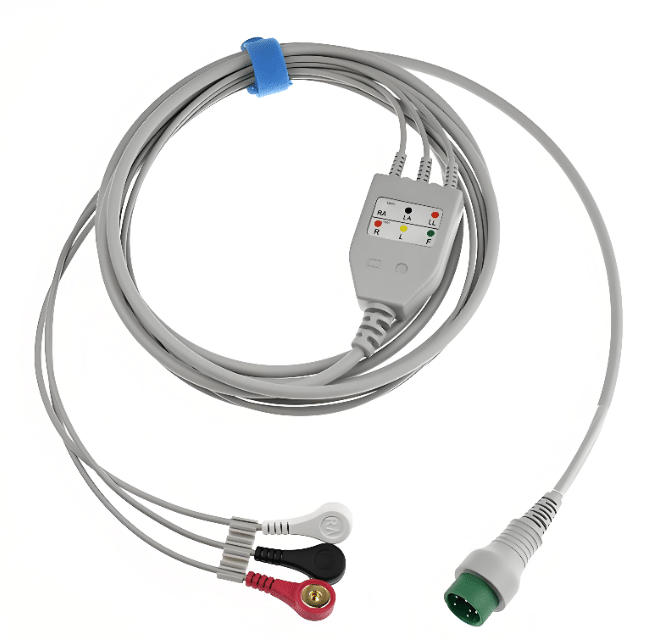

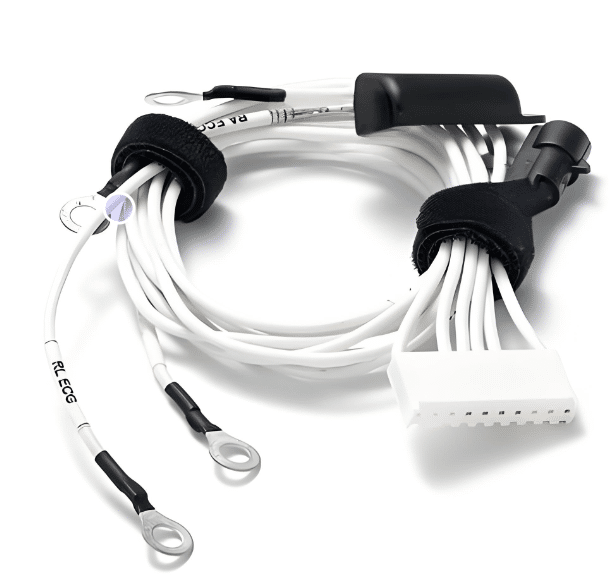

Our Products

Please explore our diverse range of medical cable assembly products.

Ultrasonic Cable Assemblies

Deliver exceptional durability, abrasion resistance, and flexibility in ultrasonic applications.

Medical Anesthesia Machine Cables

These cable assemblies utilize materials that are safe and biocompatible. Their precision mechanical design minimizes breathing resistance for patients, fully complying with medical industry standards.

Monitor Cable Assembly

High precision, real-time performance, and interference resistance are core requirements for monitoring equipment. JinHai employs premium materials and precision manufacturing to ensure this cable harness meets industry standards and your specific needs.

Retractable Cable Assembly

This cable utilizes flexible spring wire, allowing for flexible length adjustment and coiling. It is particularly suitable for mobile medical devices.

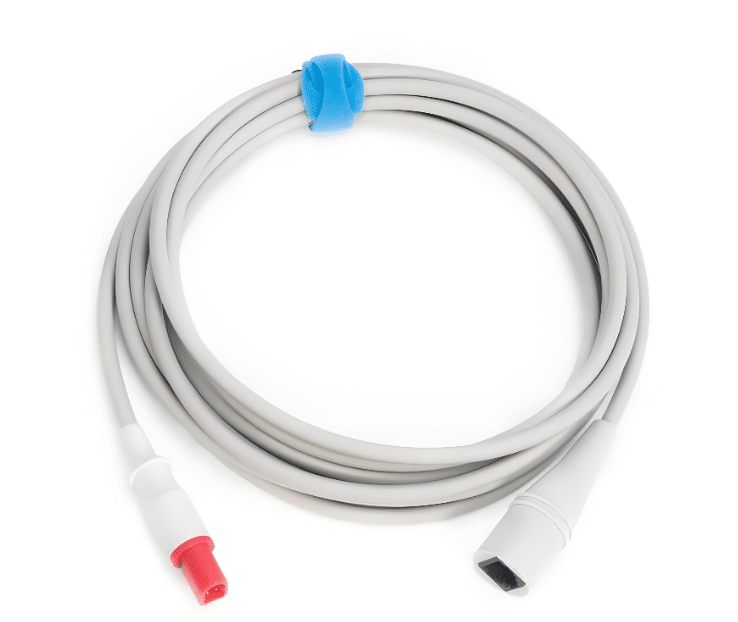

Medical Device Extension Cable

This cable is designed for external devices, enhancing the adaptability and flexibility of medical equipment.

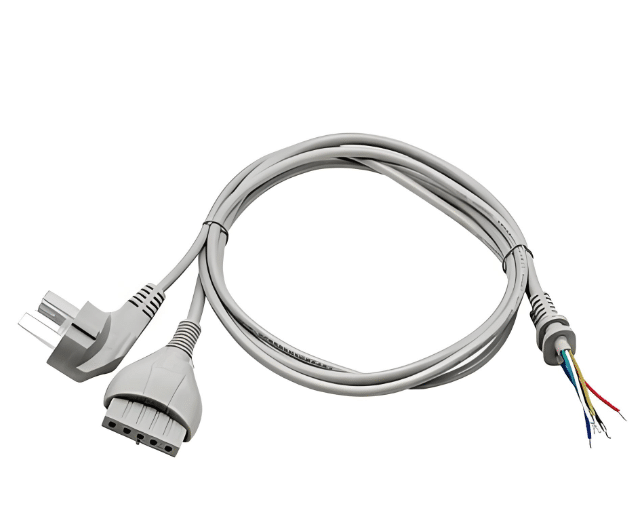

Medical Device Power Cord

A robust, sealed design combined with premium materials ensures this cable provides safe, reliable power delivery.

Looking for The Best

A medida Mazo de cables &

Cable Assembly Service?

Fast Turnaround Time

At JinHai, we ensure that custom wiring harness solutions are tailored to your needs, with quotations delivered within 12 hours to keep your projects on track.

Certified Quality Assurance

Our factory is ISO9001 and IATF16949 certified, guaranteeing the highest standards of quality, reliability, and compliance for all custom wiring harness and cable assembly services.

One-Stop Custom Solutions

We offer a complete, one-stop solution for all your wiring harness needs, from design to manufacturing, ensuring you get exactly what you need for your project.

Colaboramos con los mejores fabricantes y proveedores

Under its global strategic framework, JinHai can procure high-quality components through specialized channels.

Calidad y seguridad, Garantizado

Cumpliendo las normas IPC/WHMA-A-620, garantizamos la fiabilidad y el rendimiento de cada producto.

What is the typical shipping time for medical cables?

Depending on order size and cable complexity, orders are typically delivered within 2 to 4 weeks.

How to shield medical cables from electromagnetic interference?

Heat-shrink tubing: Utilize specialized polyolefin heat-shrink tubing to add an additional layer of protection against electromagnetic interference.

Shielded cables: Shielded cables effectively block electromagnetic interference.

Filters: Identify the frequency of electromagnetic interference and employ filters to counteract it.

What are the core factors of medical cable assemblies?

Biocompatibility: Ensures patient safety.

Electrical Performance: Shielding material combinations provide maximum protection against electromagnetic and electrical noise.

Durability: Withstands repeated sterilization cycles and sustained wear and bending.

Customization: Meets the specific requirements of various medical devices.