Custom Flat Flexible Cable (FFC) Assemblies

JinHai, as a premier domestic supplier of customized FFC assemblies, utilizes premium materials to manufacture compliant, reliable, and high-quality components.

Nuestra Clientes

Flat Flexible Cable (FFC) is a cable used to connect device components, offering advantages such as ultra-thin design and zero insertion force (ZIF). It is commonly installed in the confined spaces of modern devices like tablets, laptops, smartphones, printers, LCD monitors, and more. FFC can be nested and routed to form complete wiring harnesses.

Our Products

Our preferred connectors for customization include overmolded or integrated standard DF9 series connectors, strip-the-wire connectors for direct soldering, or ZIF-compatible connectors. For other connector requirements, please contact us.

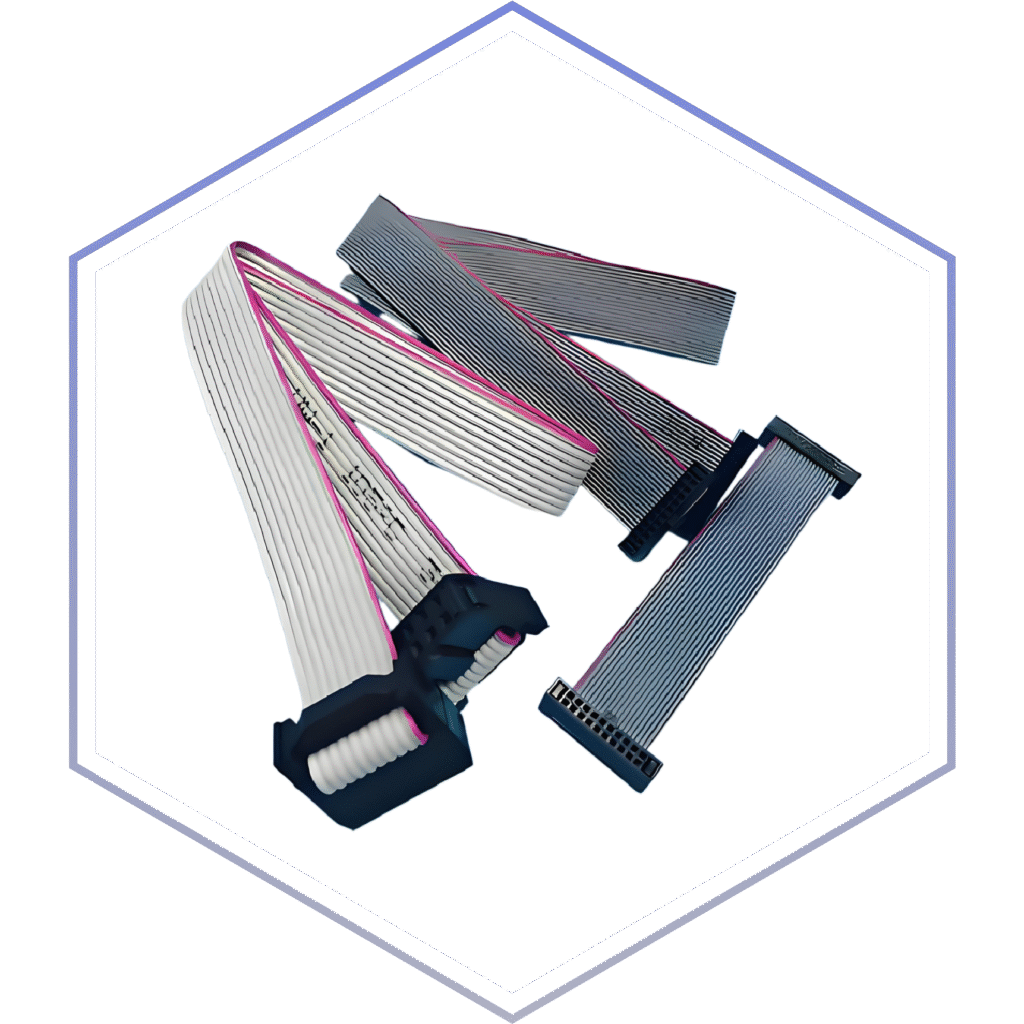

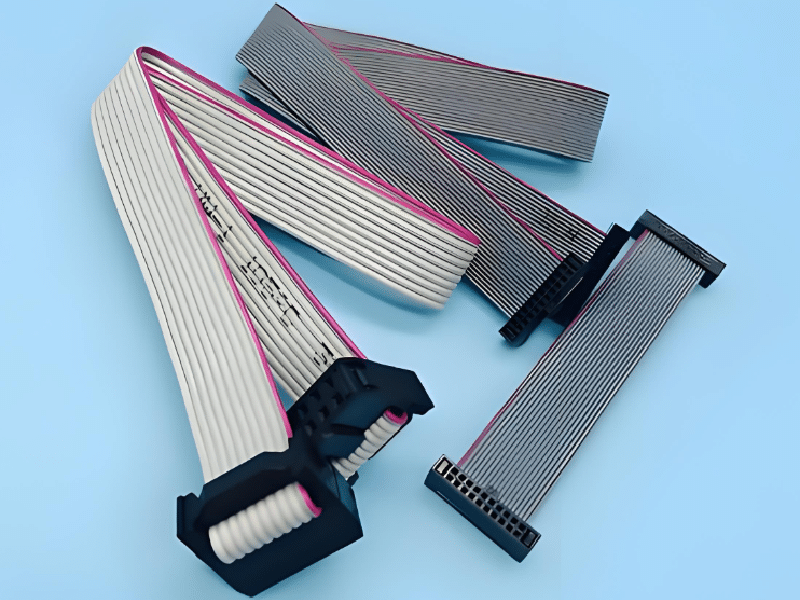

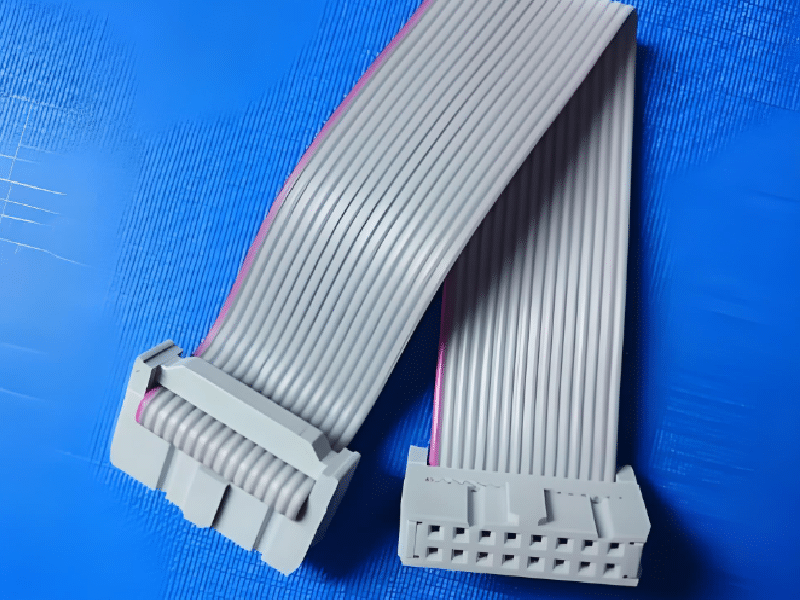

FFC Assembly with IDC Connector

Insulation Displacement Connectors (IDC) enable safe and rapid insertion and termination.

FFC assembly with independent connectors

The independent connector allows for the separate connection of individual wires, making it a versatile solution for automobiles, agricultural machinery, and consumer electronics.

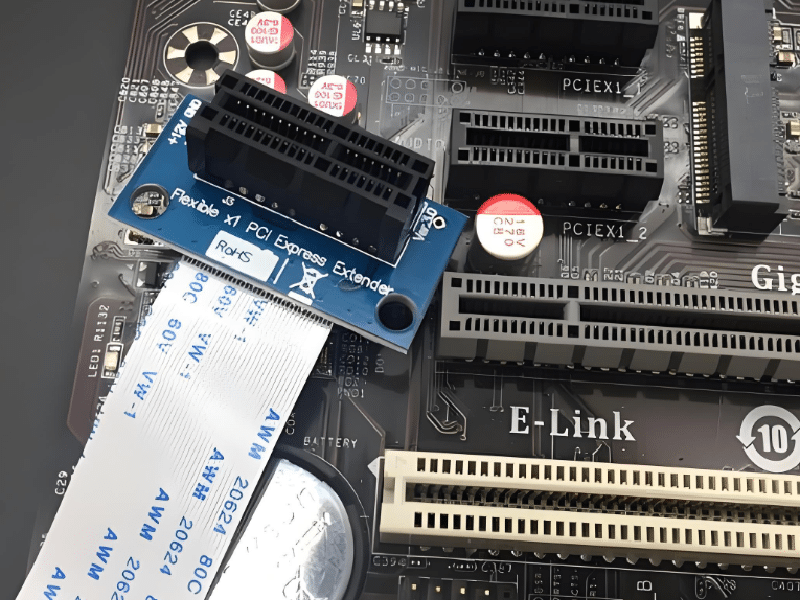

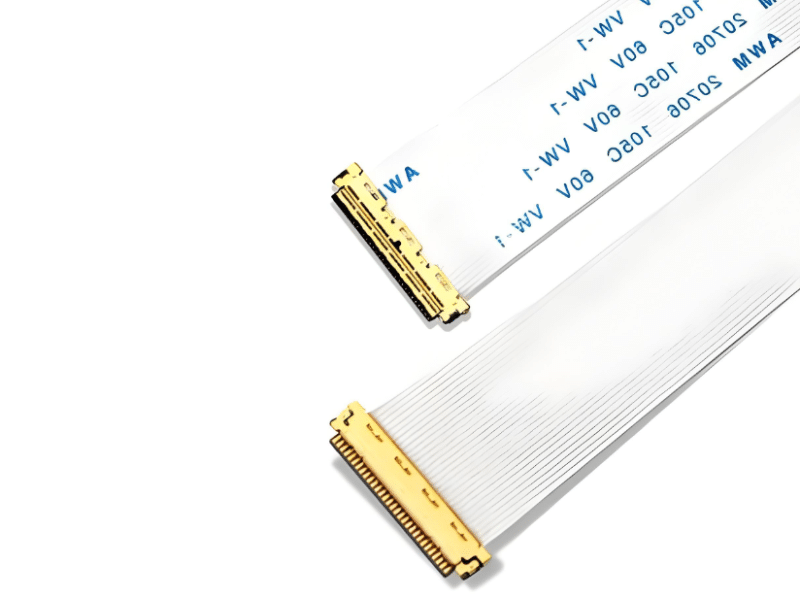

Zero Insertion Force (ZIF) FFC Assembly

The high-density pin design and ultra-thin, flattened profile make this FFC assembly ideal for space-constrained layouts.

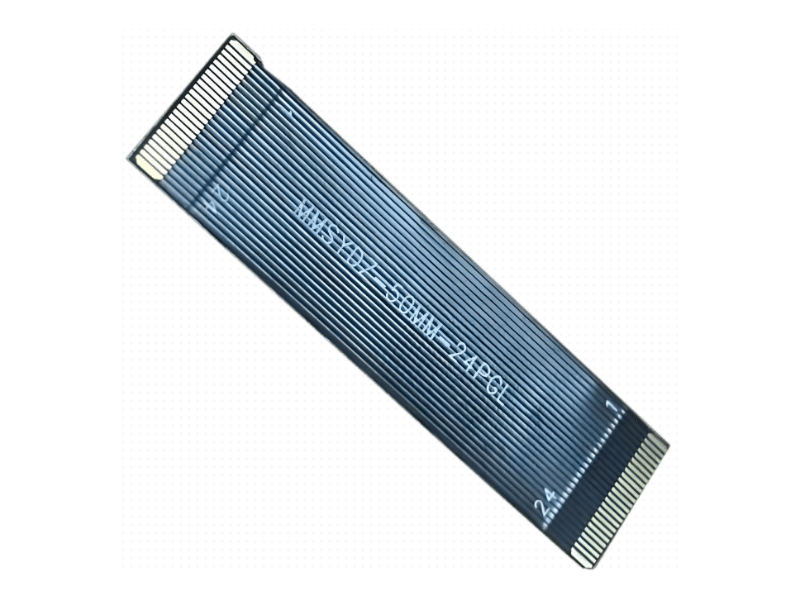

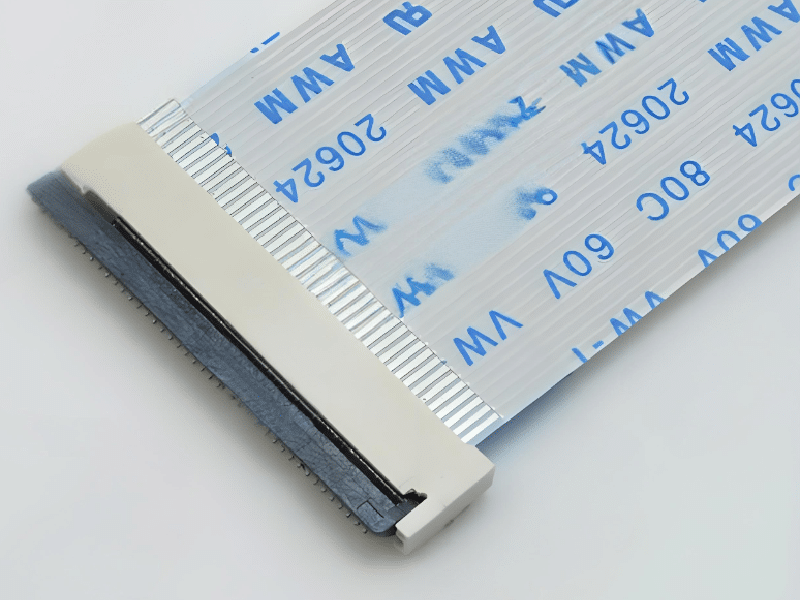

Display-Class FFC Components

These FFC assemblies connect from the driver board (T-Con board) to the side of the panel glass. They perfectly match ZIF connectors, delivering exceptional signal transmission capabilities and flat wiring performance.

Encapsulated FFC Assembly

This component features vibration resistance, a high protection rating (IP67), and high mechanical stress tolerance. These characteristics make it the preferred choice for numerous industries, including automotive, medical, and industrial automation.

FFC Assembly with Connector and TPA

The secondary lock (TPA) on the connector effectively prevents the FFC assembly from disengaging from the connector in vibrating environments.

Producto Características

Our FFC components comply with the following international standards:

REACH and RoHS Compliance

UL-certified materials Compliant with USCAR-2 and MIL-PRF standards

They also possess the following characteristics:

Resistant to high-frequency vibration High protection rating Easy installation Resistant to IEC interference

Freely Customizable Module

| Longitud | Standard lengths(3, 6,9,and12inches);Custom lengths available upon request | |

|---|---|---|

| Conductor | Fold | Accordion-style folding: Freely extends and retracts based on usage, particularly suitable for devices with adjustable components. Spiral folding: Resembles a spring shape, automatically retracts after stretching. Z-fold: A design that saves Z-axis space by folding the FFC cable in a zigzag pattern. Custom angle folding: Similar to Z-fold but allows multi-angle bending, better adapting to spatial layouts. 3D Forming: An FFC assembly shaped through heating and cooling processes, requiring precise temperature control for each fold. |

| Asphalt | 0.5 mm, 6–80 wires, for denser connections; 1.0 mm, 4–50 wires, for connections requiring higher mechanical strength. |

|

| Electroplating | Flat tinned or gold-plated copper conductor | |

| Insulation | The cables are manufactured using UL 20624-certified PET material. We can also provide high-temperature-resistant cables. |

|

| Shielding/Grounding | Aluminum laminated silver epoxy resin, providing additional electromagnetic interference protection; primarily used for grounding wires in projects. |

|

| Stress relief | Integration - Overmolding | |

| Conector | Type | Cable-to-cable configuration; Cable-to-board connection |

| Pin Definition Diagram | One-on-one; Reverse |

|

| Direction | Unidirectional output connector, bidirectional output or bidirectional input | |

Application field

The FFC cables we produce are used across a wide range of industries.

Automobile

FFC assemblies are used to connect automotive lighting systems, powertrain systems, instrument cluster display systems, and advanced driver assistance systems, each requiring FFC assemblies with different current-carrying capacities and dimensions.

Healthcare sector

For endoscopic devices (endoscopes, disposable surgical instruments), wearable or portable medical devices (holter monitors, rehabilitation robotic exoskeletons), and monitoring and diagnostic equipment (electrocardiographs, electroencephalographs, electronic blood pressure monitors, etc.).

Robot Series

FFC assemblies are ideally suited for connecting motors and sensors in robotic control systems and robotic arms/legs (military, drones, robot dogs). In these motion-intensive, space-constrained applications, they offer resistance to bending fatigue, lightweight construction, and excellent electromagnetic shielding performance.

Por qué elegir JinHai ?

We are committed to delivering fully customized connectivity solutions while ensuring comprehensive quality assurance.

Multiple Customized Solutions

We offer a variety of customized solutions to ensure all designs and performance specifications of FFC components meet your specific requirements.

Exceptional manufacturing capabilities

JinHai employs advanced manufacturing techniques to deliver orders quickly and accurately. Our technical experts are proficient in various cable gauges, connectors, and termination methods, capable of meeting virtually any requirement.

Selección de materiales

JinHai utilizes premium materials and superior manufacturing techniques to craft every FFC assembly. We deliver the highest quality service while ensuring uncompromising quality.

Years of industry experience

JinHai possesses over 20 years of wire harness manufacturing expertise, having served numerous clients across diverse industries including consumer electronics, base stations, and defense applications. Our exceptional product quality has earned the long-term trust and success of our customers.

Calidad y seguridad, Garantizado

Cumpliendo las normas IPC/WHMA-A-620, garantizamos la fiabilidad y el rendimiento de cada producto.

What is the difference between FFC and FPC?

FFC typically employs straight conductors with pin configurations of 1-to-1 or 1-to-n. In contrast, FPC offers greater flexibility, featuring diverse pin arrangements, multi-layer structures, and the capability for conductor cross-connections.

How many specifications are there for FFC?

FFC comes in various pitch specifications, such as 0.15 mm, 0.2 mm, 0.3 mm, 0.5 mm, and 1.00 mm.

What is the voltage rating of the FFC cable?

Rated voltage: 50V AC.

How to determine the required pin pitch for FFC cables?

You can determine the spacing based on specific applications. For instance, 0.3mm to 0.5mm is suitable for high-density compact designs (such as digital cameras, tablets, and medical devices). Spacing of ≥1.0mm is more appropriate for industrial equipment (such as printers, scanners, and home appliances).