Premium Custom Wire Harness Manufacturer

As a core member of the Wire Harness Manufacturers Association, we not only hold standard certifications across various industries but also produce a wide range of high-quality custom wire harnesses.

لدينا العملاء

Contract manufacturing services offer your business the following benefits:

cost-effectiveness

Labor expenses, raw material costs, administrative expenses, and operational costs—as the four core expense categories for enterprises—can all be significantly reduced through outsourcing.

Professionalism

Professional wire harness manufacturers possess extensive manufacturing experience and advanced equipment, enabling them to produce a wide variety of wire harnesses and deliver high-quality products with greater consistency.

المرونة

Opt for flexible approaches by partnering with multiple manufacturers equipped with production facilities capable of meeting your customization requirements.

Manufacturing Process

Our advanced manufacturing and inspection equipment form the core of ensuring consistent and stable production throughout critical processes.

Prototype Manufacturing

For prototype samples, conduct 200% inspection on each individual process to ensure physical items match the design specifications.

If you need custom wire harness manufacturing or OEM services, please choose JinHai as your manufacturer!

Submit A Quick Quote

لماذا تختار جينهاي ?

JinHai is a company founded on the cornerstones of integrity and quality, committed to ensuring quality, efficiency, and sustainable development.

حلول مخصصة حسب الطلب

From design and raw material selection to mass production, we maintain close collaboration throughout the entire process to deliver the highest-performing wire harnesses for your needs.

Highly Experienced

JinHai has been in the wire harness industry for over 28 years. Our wire harnesses serve a wide range of sectors including home appliances, motorcycles, automobiles, industrial equipment, medical devices, and drones.

Superior Craftsmanship

Our factory is equipped with state-of-the-art machinery, ranging from bench-top crimping machines to fully automated crimping systems and innovative technologies. We ensure every delivered wire harness is reliable, durable, and maintains exceptional quality consistency.

Full-Process Support

We provide comprehensive support throughout the entire manufacturing process, from initial design to after-sales service.

Quality Assurance

To ensure compliance with industry standards, we maintain a rigorous testing and analysis system. This includes multiple testing facilities, automated testing equipment, and a dedicated inspection team responsible for executing, validating, and testing all inspection procedures.

Supply Chain Advantages

We have established long-term strategic partnerships with numerous premium global suppliers, including TE, MOLEX, and JST. This enables us to simultaneously ensure product quality and achieve lower procurement costs during sourcing.

Unrivaled Manufacturing Capabilities

JinHai’s customized solutions meet your specification requirements with superior craftsmanship and technology.

Manufacturing Support

Design support from prototyping to mass production. Comprehensive solutions including crimping, soldering, ultrasonic welding, cutting, marking, and more.

Assembly Services

Markings, text, or logos applied to wire harnesses, secured with cable ties or adhesive tape. Selectable wire gauge, conductor count, insulation type, and color. To ensure consistent quality, we perform 100% functional testing and dimensional measurement.

Wire Harness Functionality

Customized solutions for corrosive, wet, dusty, and high-temperature environments.

Connector Types

Diverse connector options including AMP, Molex, JST, Yazaki, THB, HL, and more.

Covering Materials

Multiple covering materials available: PVC, heat shrink tubing, XLPE, silicone, rubber, nylon, braided mesh, etc.

Dimensions and Voltage

Wire lengths customized to electrical load requirements. Multiple wire gauges available from 30 AWG to 0 AWG based on current, layout application, and operating environment.

Industry Compliance

Strict adherence to industry standards including TF16949, RoHS 2.0, UL, and REACH.

وصلات الأسلاك المخصصة

Unveiling Our Range of Custom Wire Harnesses and Components.

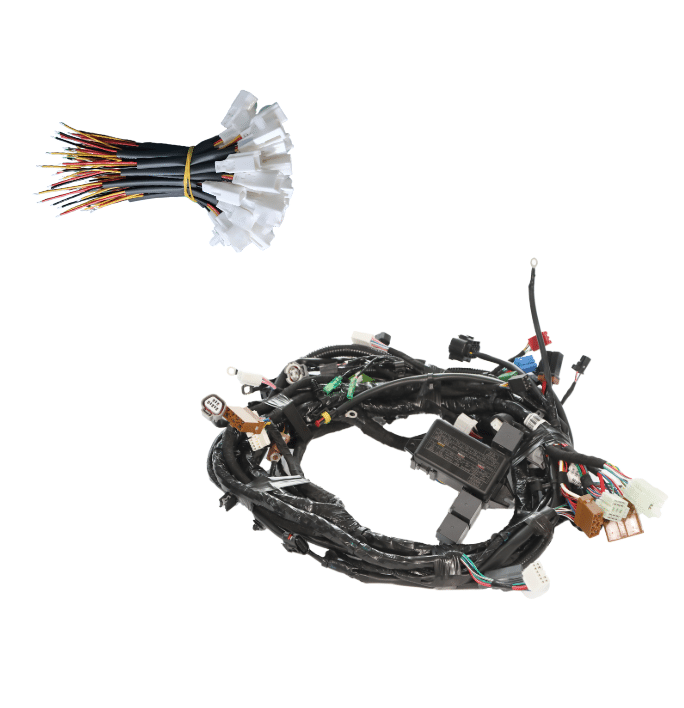

Instrument Wire Harness

وصلة أسلاك المحرك

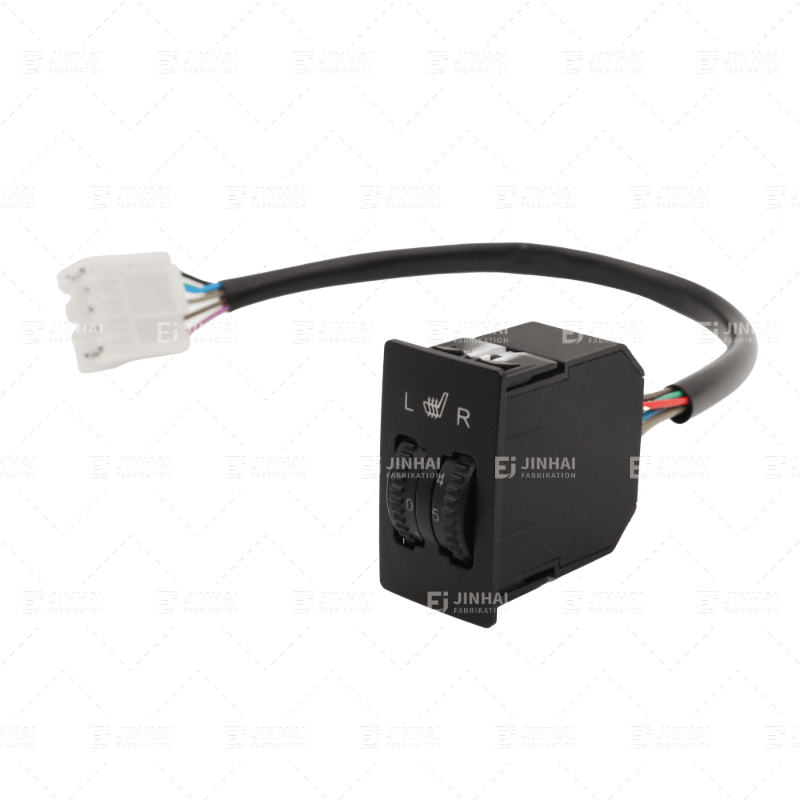

MINI Round Heating Switch

مفتاح تدفئة المقعد مزدوج اللمس

ECG Cable Harness

Economy Commuter Wire Harness

ما يقوله عملاؤنا

What is the minimum order quantity?

At JinHai, we define MOQ based on different harness types. Below are JinHai’s internal minimum order quantities:

- Simple harnesses (consumer electronics or small appliance internal harnesses)

- MOQ: 500–2000 pieces;

- Moderately complex harnesses (industrial harnesses, agricultural machinery harnesses, low-voltage automotive harnesses)

- MOQ: 1,000–5,000 pieces;

- Highly Complex Harnesses (e.g., engine harnesses, chassis harnesses, instrument panel harnesses)

- MOQ: 5,000+ pieces

- Fully Customized Harnesses

- JinHai determines MOQ based on complexity and cost considerations: 2,000–5,000 pieces;

Delivery Lead Times for Custom Orders?

Regarding order cycles, JinHai will clearly communicate order quantities and determine lead times based on order volume. Below are JinHai’s typical lead times for different order quantities:

- Small-batch custom orders (100–500 pieces): Due to lower volumes and the need to procure many raw materials on a spot basis, pre-production preparation takes longer. Lead times typically range from 2 to 5 weeks.

- Large-volume custom orders (over 1,000 units): Due to the large order quantity and significant raw material requirements, some materials are sourced from distributors. This may necessitate adjusting allocation ratios or require factory time for verification. Therefore, the typical production cycle ranges from 8 to 20 weeks. Additionally, the cycle may extend due to special circumstances (e.g., shipping weather conditions, tariff fluctuations).

Quality Control Measures in Production?

- Incoming Material Inspection

- Wires and terminals are sampled and tested based on the supplier’s shipping report to verify wire strand count, wire diameter, color, terminal plating thickness, and dimensions. Connectors are sampled and tested for dimensional compliance against official drawings.

- Process Inspection

- Wire Cutting/Crimping Process: Initial, patrol, and final inspections are conducted per CP requirements. Patrol inspections occur at a frequency of 2 hours per shift.

- Pre-assembly Process: Insertion follows the “insert, listen twice, pull back” procedure.

- Assembly Process: First, verify seal installation. Second, confirm secondary locking of connectors and primary locking of terminals.

- Final Inspection

- Inspectors conduct 100% dimensional checks of harnesses using tape measures/steel rulers;

- Perform 100% electrical functionality testing on finished harnesses using dedicated harness electrical test benches;

- Quality inspectors conduct final checks on harness appearance, material integrity (clips/tie wraps), label content, and clarity;

- The Quality Department periodically samples from qualified products for more stringent full-dimension measurements and functional testing to ensure production process stability;

- Traceability Assurance

- Each harness is assigned a unique label serial number, traceable through the labeling system. This enables rapid identification of the source and isolation of problematic products in the event of an issue.

Logistics Methods

JinHai offers multiple logistics options:

- International Express Delivery: Ideal for sample shipments. Couriers assist with customs clearance. JinHai currently partners with DHL, TNT, and EMS.

- International Air Freight: Suitable for small-batch product deliveries. Offers faster transit times than sea or rail freight with high security.

- International Sea Freight: The most prevalent shipping method in international trade, suitable for bulk order shipments with flexible containerization options.

- International Rail Transport: Also suitable for bulk order shipments, primarily serving the China-Europe corridor.

Quality Control Measures in Production?

- Incoming Material Inspection

- Wires and terminals are sampled and tested based on the supplier’s shipping report to verify wire strand count, wire diameter, color, terminal plating thickness, and dimensions. Connectors are sampled and tested for dimensional compliance against official drawings.

- Process Inspection

- Wire Cutting/Crimping Process: Initial, patrol, and final inspections are conducted per CP requirements. Patrol inspections occur at a frequency of 2 hours per shift.

- Pre-assembly Process: Insertion follows the “insert, listen twice, pull back” procedure.

- Assembly Process: First, verify seal installation. Second, confirm secondary locking of connectors and primary locking of terminals.

- Final Inspection

- Inspectors conduct 100% dimensional checks of harnesses using tape measures/steel rulers;

- Perform 100% electrical functionality testing on finished harnesses using dedicated harness electrical test benches;

- Quality inspectors conduct final checks on harness appearance, material integrity (clips/tie wraps), label content, and clarity;

- The Quality Department periodically samples from qualified products for more stringent full-dimension measurements and functional testing to ensure production process stability;

- Traceability Assurance

- Each harness is assigned a unique label serial number, traceable through the labeling system. This enables rapid identification of the source and isolation of problematic products in the event of an issue.