Roof Wiring Harness Communication Standard

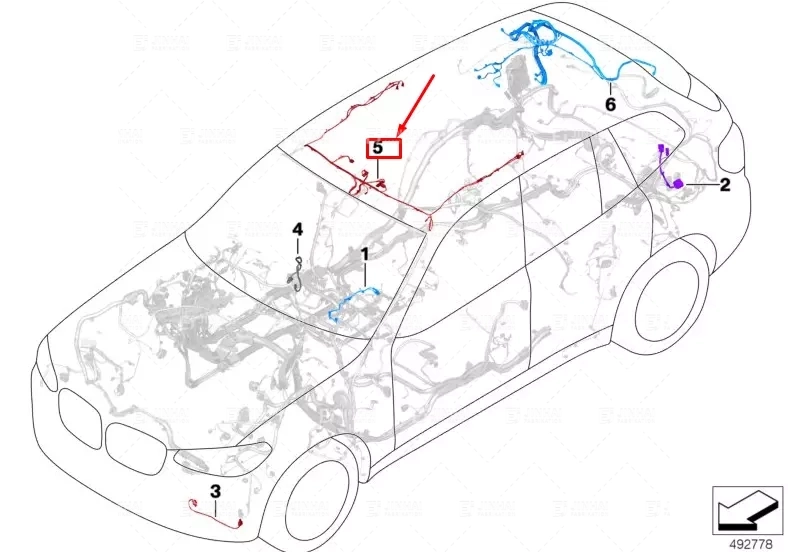

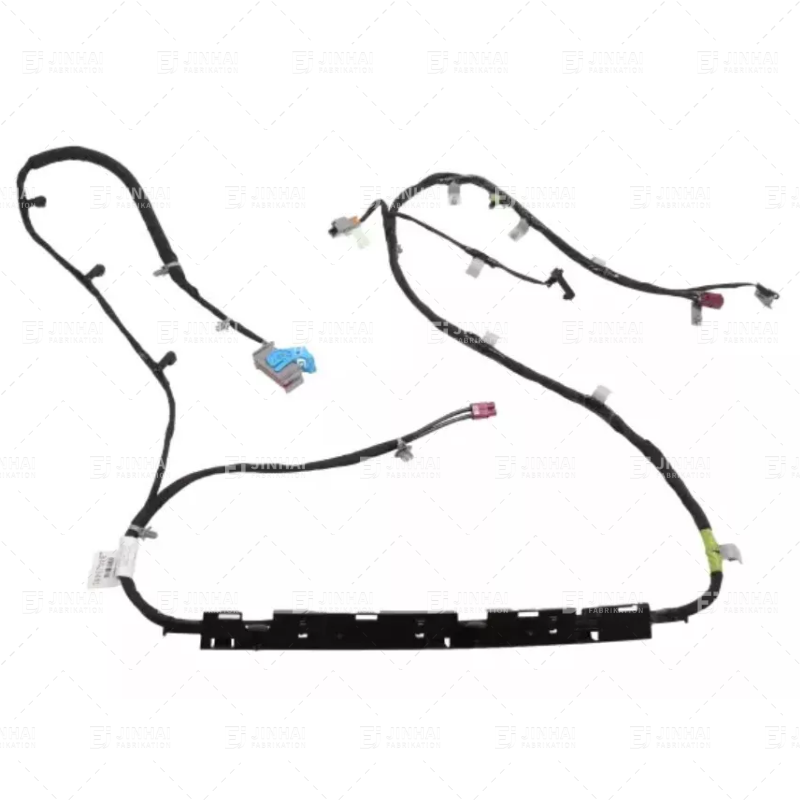

Ceiling area equipment mostly uses a layered communication architecture, and the protocol selection needs to match the device characteristics:

| Device Type | Recommended Agreement | Rate/Characteristics | Application Cases |

| Sunroof motor/sensor | LIN bus | 20Kbps, single line low cost | Door glass control |

| In-car entertainment system | MOST | 150Mbps, optical fiber transmission with anti-interference | Audio and video signal transmission |

| Rain/light sensor | CAN-FD | 2Mbps, high real-time performance | Automatic wiper linked with ECU |

Contact us immediately to learn how we can meet your cable and harness requirements. Follow us on Youtube .