Automotive Door Wiring Harness Communication Standard

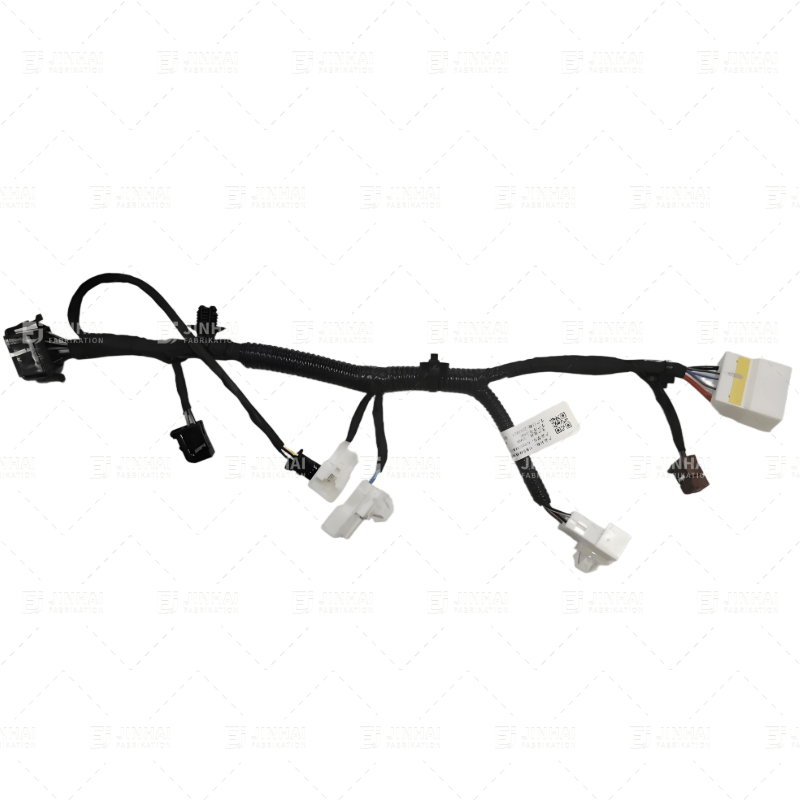

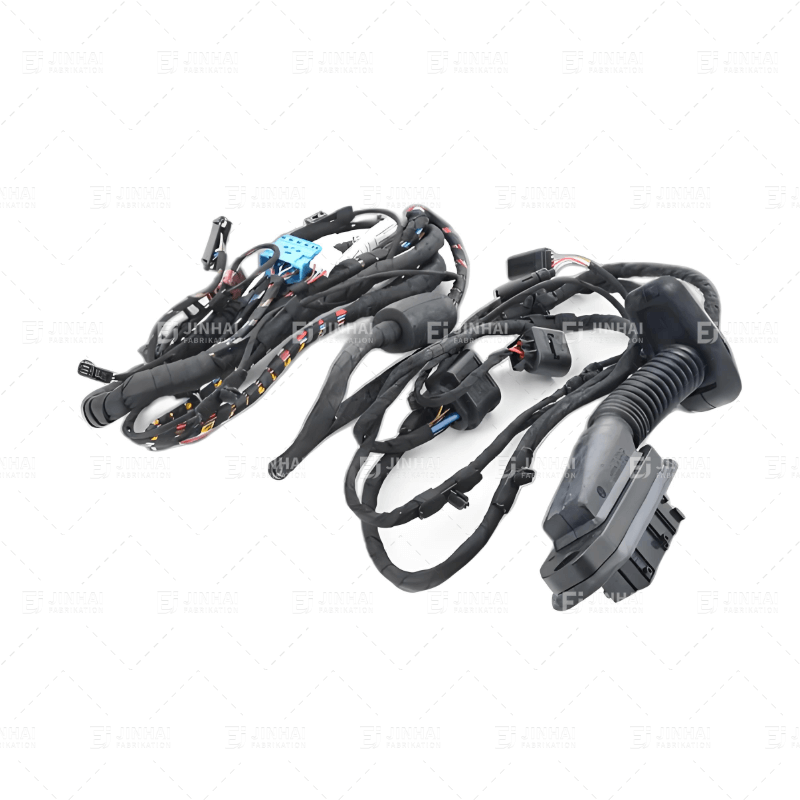

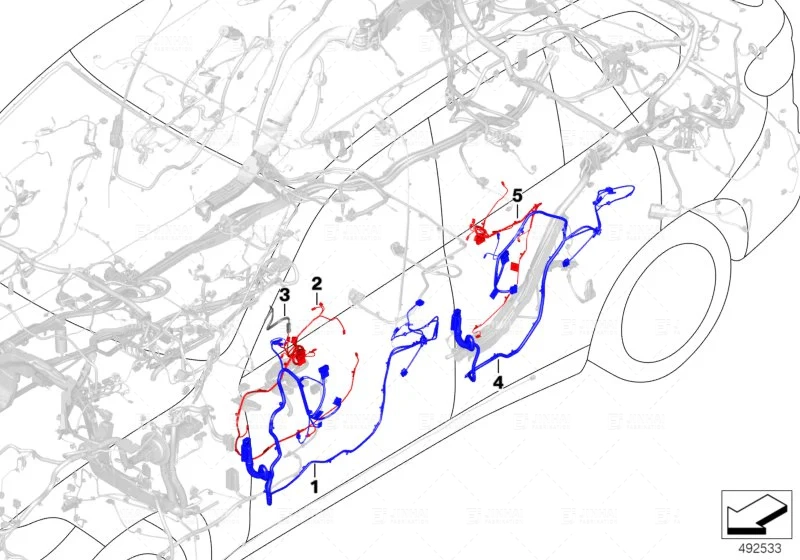

Door panel wiring harnesses must be compatible with multi-protocol communication networks:

- Low-speed control: The LIN protocol (≤20kbps) is used for basic functions such as door locking and window lifting. It is low-cost and highly resistant to interference.

- Medium-speed data transmission: The CAN bus (1Mbps) supports real-time control such as rearview mirror adjustment and ambient light color synchronization.

- Future trend: Ethernet (100Mbps and above) will gradually replace traditional buses to meet the high-bandwidth requirements of autonomous driving sensors.

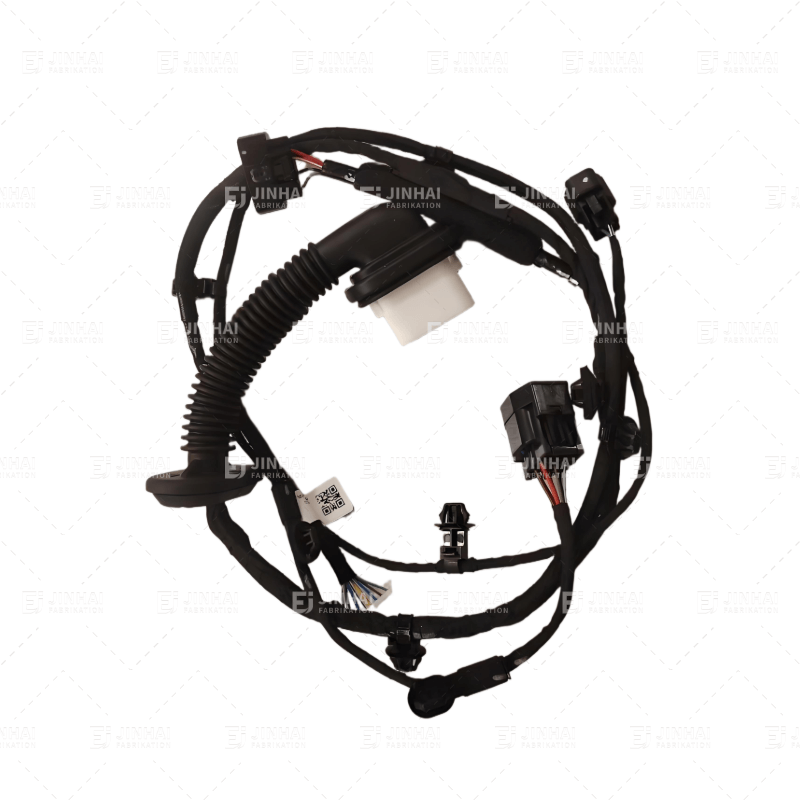

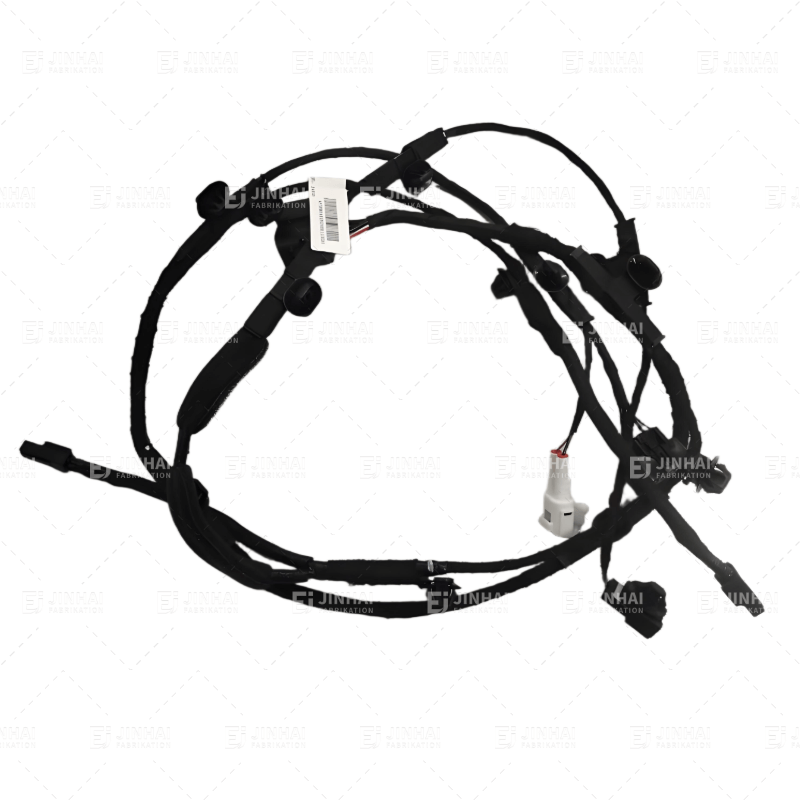

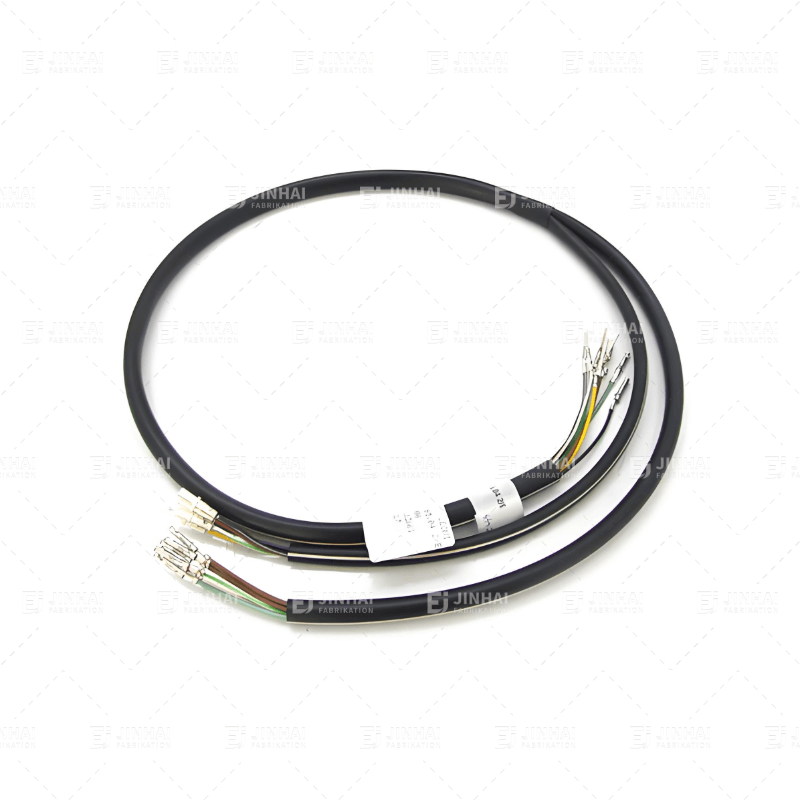

Contact us today to find out how we can fulfil your cable and wire harness needs.Follow us on Youtube and Facebook.