What Are Wire Harness Terminal

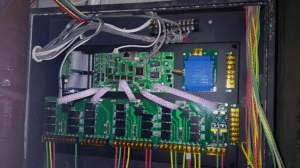

Wire harness terminals connect wires within harnesses and secure cable ends, serving as core components for stable connections between wires and electrical elements like switches and sensors. Widely used in automotive and electronics, they require selection based on type and material.

Types of Wire Harness Terminals

Wire harness terminals are categorized into blade series, cylindrical series, and connector series.

- Flat terminals: Made from H65Y or H70Y material with thicknesses of 0.3–0.5 mm.

- Cylindrical terminals: Made from H65Y or Qsn6.5-0.1 material with thicknesses of 0.3–0.4 mm.

- Connector series terminals: Divided into U-shaped, fork-shaped, and hole-shaped types.

- U-shaped terminals use H62Y2, H65Y, H68Y, or Qsn6.5-0.1 materials with thicknesses of 0.4–0.6 mm.

- Fork terminals (also known as Y-shaped terminals) use H62Y2 material with thicknesses of 0.4–0.6 mm. Some surfaces are nickel-plated for excellent conductivity.

- Hole terminals generally use H65Y or H65Y2 as base materials, with material thickness ranging from 0.5 to 1.0 mm.

Wire Harness Terminal Materials

Wire harness terminals require selection of different materials based on electrical performance, mechanical properties, and application environments.

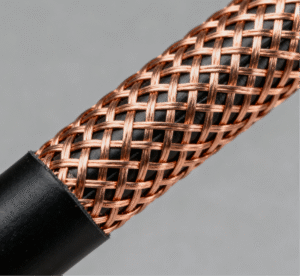

- Copper Alloys: The most commonly used terminal material, offering excellent conductivity and ductility.

- Brass: Lower cost, used in motorcycle applications, with good mechanical properties;

- Phosphor bronze: Used in smart home and agricultural machinery applications, offering higher mechanical strength and fatigue resistance;

- Beryllium copper alloy: Used in automotive and aerospace applications, featuring extremely high mechanical strength and conductivity;

- Steel and stainless steel materials: Used in humid or corrosive environments, with relatively poor conductivity.

- Aluminum: Excellent conductivity and lightweight, applied in specialized fields.

- Composite wire harness terminals: Examples like copper-clad aluminum offer superior conductivity, light weight, and low cost.

In automotive and aerospace sectors, precious metals like silver, gold, or tin are plated onto copper substrates to enhance electrical performance and oxidation resistance.

Wire Terminal Selection Principles

Material selection requires comprehensive consideration of application environment, mechanical stress, electrical conductivity, and cost factors to achieve optimal performance-cost balance.

Specific Selection Principles

- Electrical Performance: Rated current, voltage, contact resistance, and other metrics.

- Rated Current: Determined based on maximum operating current while accounting for terminal temperature rise limits.

- Voltage Rating: Must meet operating voltage under extreme system conditions.

- Mechanical Properties: Evaluate parameters like insertion force, extraction force, holding force, and cycle life.

- Operating Environment: Consider operating temperature range, moisture resistance, salt spray resistance, and chemical corrosion resistance.

- Connection Method: Crimp, solder, or screw connection; compatibility between wire gauge and terminal.

Final selection should achieve the optimal balance between technical feasibility and economic viability by comprehensively considering commercial factors such as cost, supply lead time, and after-sales response speed, while ensuring compliance with technical requirements.

Conclusion

As core connection components in equipment electrical systems, Wire Harness Terminal play a critical role in the electrical performance and functional stability of the entire system.

This article provides professional guidance for technical decision-making across various fields by explaining key technologies including terminal types, materials, selection criteria, and manufacturing processes.

Contact us immediately to learn how we can meet your cable and harness requirements. Follow us on Youtube .