This article explores professional custom wire harness processes, specialized reverse engineering techniques, and existing manufacturing equipment to demonstrate why JinHai is a trusted partner.

Core Advantages of Custom Wire Harness

While standardized harnesses fulfill basic functional needs, customized solutions deliver stronger competitive advantages:

- Product Lightweighting: In automotive, aerospace, and mobile device sectors, optimized wiring design and lightweight materials enable more efficient layouts and reduced weight.

- Environmental Adaptability: Custom harnesses utilize specialized insulation materials, sheathing, and sealing techniques to ensure electrical systems function reliably in extreme environments.

- Performance Optimization:Delivering optimal solutions enhances signal integrity and resistance to interference.

- Industry-Specific Solutions: Tailored services deliver precise solutions addressing unique requirements across diverse sectors.

JinHai Custom Wire Harness Full Process

The wire harness customization process encompasses design drawings, production, testing, and delivery. The workflow is as follows:

- Step 1: Requirements Analysis & Solution Design: This is the critical foundation of the entire project.

- Requirement Communication: JinHai manufacturers engage in thorough discussions with clients to deeply understand customized needs, including functionality and budget constraints.

- Technical Solution Design: Develop a detailed wiring plan based on client requirements. Define all cable routing paths, lengths, branching points, wire specifications, color codes, connector types, and pin definitions.

- Step 2: Material Selection and Procurement

- Confirm material specifications and quantities based on provided drawings or 3D models.

- Procure raw materials according to the procurement contract after the design plan is finalized.

- Step 3: Production and Assembly: Conduct small-batch production

- Wire Preparation: Cut conductors to length per drawings.

- Wire Stripping: Precisely remove insulation from conductors.

- Terminal Crimping: Securely attach terminals to wire ends using specialized tools—critical for electrical integrity.

- Connector Insertion: Insert crimped wires into corresponding connector ports as defined by drawings until locked in place.

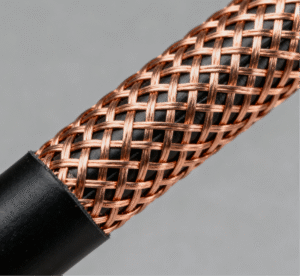

- Assembly and Bundling: Integrate all branch circuits into the main trunk and bundle using tape, cable ties, or braided mesh tubing to form a complete harness.

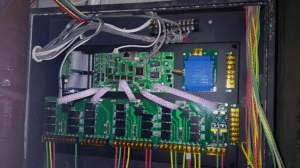

- Step 4: Quality Control and Testing

- Quality control spans the entire production process. Finished products undergo 100% electrical testing on dedicated test benches to verify harness continuity. Test items include:

- Continuity Testing: Detects open circuits in wiring.

- Short Circuit/Misrouting Testing: Ensures no unintended connections exist.

- Pin Definition Verification: Checks each connector pin matches design drawings.

- Visual Inspection: Confirms no damage and clear labeling.

- Quality control spans the entire production process. Finished products undergo 100% electrical testing on dedicated test benches to verify harness continuity. Test items include:

- Step 5: Packaging and Delivery

- Small-batch products undergo customer testing before mass production.

- Products are packaged in airtight containers with installation instructions or diagrams, then delivered to customers via logistics.

Custom Wire Harness: Reverse Engineering Technology

Applicable for repairing harness issues in legacy equipment and competitor analysis. When electrical schematics and specifications are unavailable, reverse engineering becomes the critical technology for reconstructing designs and clarifying harness functionality.

Purpose and Challenges of Harness Reverse Engineering

The core objective is to recreate complete, accurate design documentation (including schematics, BOM lists, 2D/3D drawings) by analyzing physical samples without electrical design drawings.

Challenges include ambiguous connector interfaces, unclear component models, and internal structures obscured by sealed materials.

Standard Workflow for Harness Reverse Engineering

The standard reverse engineering workflow comprises the following steps:

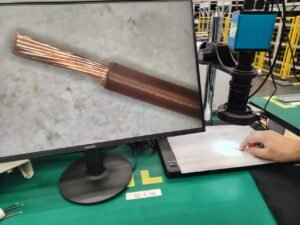

- Sample Preparation and Data Collection: Capture detailed photographs and videos of the original harness sample to document its condition. Use precision tools—including steel rulers (0.1mm accuracy), vernier calipers (0.001mm accuracy), electronic magnifiers, and even 3D scanners—to accurately measure overall dimensions, branch lengths, and mounting point locations.

- Disassembly and Component Identification: Dismantle the harness, number and label each connector, terminal, and wire. Identify the model and manufacturer information for each component.

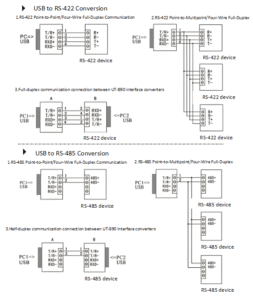

- Signal types cannot be determined solely from the harness itself. Analysis of the circuitry on the device’s PCB board or measurement of pin voltages and waveforms during device operation is required for identification.

- Communication protocol identification can be inferred using dynamic analysis tools.

- Encapsulated/Sealed Components: For components sealed with encapsulation material, non-destructive X-ray imaging is required to view internal connections, or the sealant must be scientifically removed layer by layer.

- Circuit Mapping and Schematic Drawing: Use a multimeter or harness continuity tester to verify the connection status of each pin.

- Technical documentation creation:Compile all mapped data into standardized electrical schematics and 2D engineering drawings using professional software like AutoCAD or EPLAN.

- Analysis and improvement:Analyze original harness designs to identify flaws, optimize routing for stress reduction, replace components with higher reliability, or refine manufacturing processes.

Custom Wire Harness Manufacturing Equipment

Efficient manufacturing equipment forms the foundation for producing high-quality harnesses.

Wire Harness Manufacturing Equipment

- Automated Wire Cutting and Stripping Machine:

- Integrates wire feeding, cutting, and stripping functions. Wire gauge is specified in AWG or mm².

- Laser stripping machines are used for special products, enabling non-contact, damage-free stripping.

- Manual/Automatic Terminal Crimping Machine

- Efficiently performs multiple processes including crimping, single-end crimping, or double-end crimping.

Testing Equipment

- Continuity Tester: Primarily used to verify the correctness of electrical connections in wire harnesses, serving as a crucial quality inspection instrument.

- Pull-out Tester:Employed for sampling or first-article inspection to test whether the pull-out force after terminal crimping meets standards.

- High-Voltage Tester:Performs insulation and withstand voltage tests on wire harnesses to ensure safety and stability under rated voltage.

Auxiliary Equipment and Tools

- Stranding Machine:Used to organize the cores of multi-strand conductors.

- Tape Wrapping Machine:Semi-automatic or fully automatic completion of wire harness tape wrapping, offering significantly higher efficiency and consistency than manual operation.

- Heat Gun/Heat Shrink Tubing Heating Equipment:Used to heat and shrink heat shrink tubing.

- Fixture Boards and Clamps:Secure wires during assembly to ensure accurate harness dimensions and branch routing.

Summary

JinHai is dedicated to being a trusted global manufacturer of customized wire harness solutions. We possess advanced manufacturing equipment and adhere to rigorous production/process standards, while strictly following IATF16949 and ISO9001 quality management systems to ensure high-quality and stable performance. Choose JinHai to accelerate your project’s success—JinHai grows alongside your projects!

Contact us immediately to learn how we can meet your cable and harness requirements. Follow us on Youtube .