AWG Meaning

Wire refers to conductor material, while Gauge denotes the aperture size of wire drawing dies.

Standard wires are manufactured through multiple die sets, drawn from larger to smaller diameters. The gauge number indicates the number of drawing passes.

AWG numbers are inversely proportional to wire diameter—lower numbers signify fewer drawing passes. The wire’s cross-sectional area determines its safe current capacity.

Analysis of 6 AWG Wire Characteristics

6 AWG wire is a copper conductor with the following physical dimensions:

- Diameter calculation: D(AWG) = .005 × 92 × ((36 – AWG) / 39)

- Cross-sectional area: 13.30 mm² or 0.0206 in²

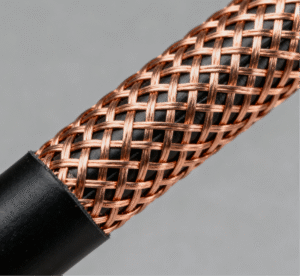

Common materials include aluminum wire, copper-clad aluminum wire, stranded wire, and tinned copper wire. Different materials affect the diameter and current-carrying capacity of 6 AWG wire.

Current-Carrying Capacity of 6 AWG Wire

Current-carrying capacity refers to the maximum continuous current a wire can handle under specific environmental conditions. At 75°C (167°F), the current-carrying capacity of 6 AWG wire is 65A.

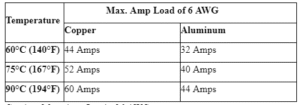

Maximum Ampere Load for 6 AWG Wire

With a current-carrying capacity of 65A, 6 AWG wire can safely handle a maximum current of 52 amperes.

Calculation Method for Amperage:

- Maximum Ampere Load (per 80% NEC Standard) = 65 x 0.8 = 52 amperes.

Factors Affecting 6 AWG Wire Current Capacity

-

Insulation Temperature Rating

- ○Different insulation materials correspond to different temperature ratings. Higher ratings allow conductors to handle greater currents.

-

Ambient Temperature

- Current capacity tables assume constant temperatures. If operating temperatures exceed these constants, wire cooling efficiency decreases, requiring derating of the wire’s current capacity.

-

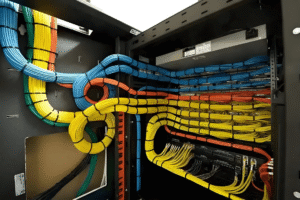

Wiring Configuration

- Wiring layout directly impacts heat dissipation, thereby affecting current capacity.

Standard wiring configurations include:

-

Conductor Materials

- Different conductor materials affect current-carrying capacity.

AWG Wire Voltage Drop

Wires inherently possess resistance, causing current loss during transmission. The voltage difference between the initial and terminal ends constitutes the voltage drop. Longer wires require thicker wire gauges to ensure adequate voltage supply at the terminal.

AWG Wire Size Reference Chart

| AWG gauge | Conductor

Diameter Inches |

Conductor

Diameter mm |

Conductor cross section in mm2 |

| 0000 | 0.46 | 11.684 | 107 |

| 000 | 0.4096 | 10.40384 | 84.9 |

| 00 | 0.3648 | 9.26592 | 67.4 |

| 0 | 0.3249 | 8.25246 | 53.5 |

| 1 | 0.2893 | 7.34822 | 42.4 |

| 2 | 0.2576 | 6.54304 | 33.6 |

| 3 | 0.2294 | 5.82676 | 26.7 |

| 4 | 0.2043 | 5.18922 | 21.1 |

| 5 | 0.1819 | 4.62026 | 16.8 |

| 6 | 0.162 | 4.1148 | 13.3 |

| 7 | 0.1443 | 3.66522 | 10.6 |

| 8 | 0.1285 | 3.2639 | 8.37 |

| 9 | 0.1144 | 2.90576 | 6.63 |

| 10 | 0.1019 | 2.58826 | 5.26 |

| 11 | 0.0907 | 2.30378 | 4.17 |

| 12 | 0.0808 | 2.05232 | 3.31 |

| 13 | 0.072 | 1.8288 | 2.63 |

| 14 | 0.0641 | 1.62814 | 2.08 |

| 15 | 0.0571 | 1.45034 | 1.65 |

| 16 | 0.0508 | 1.29032 | 1.31 |

| 17 | 0.0453 | 1.15062 | 1.04 |

| 18 | 0.0403 | 1.02362 | 0.823 |

| 19 | 0.0359 | 0.91186 | 0.653 |

| 20 | 0.032 | 0.8128 | 0.519 |

| 21 | 0.0285 | 0.7239 | 0.412 |

| 22 | 0.0253 | 0.64516 | 0.327 |

| 23 | 0.0226 | 0.57404 | 0.259 |

| 24 | 0.0201 | 0.51054 | 0.205 |

| 25 | 0.0179 | 0.45466 | 0.162 |

| 26 | 0.0159 | 0.40386 | 0.128 |

| 27 | 0.0142 | 0.36068 | 0.102 |

| 28 | 0.0126 | 0.32004 | 0.080 |

| 29 | 0.0113 | 0.28702 | 0.0647 |

| 30 | 0.01 | 0.254 | 0.0507 |

| 31 | 0.0089 | 0.22606 | 0.0401 |

| 32 | 0.008 | 0.2032 | 0.0324 |

| Metric 2.0 | 0.00787 | 0.200 | 0.0314 |

| 33 | 0.0071 | 0.18034 | 0.0255 |

| Metric 1.8 | 0.00709 | 0.180 | 0.0254 |

| 34 | 0.0063 | 0.16002 | 0.0201 |

| Metric 1.6 | 0.0063 | 0.16002 | 0.0201 |

| 35 | 0.0056 | 0.14224 | 0.0159 |

| Metric 1.4 | .00551 | .140 | 0.0154 |

| 36 | 0.005 | 0.127 | 0.0127 |

| Metric 1.25 | .00492 | 0.125 | 0.0123 |

| 37 | 0.0045 | 0.1143 | 0.0103 |

| Metric 1.12 | .00441 | 0.112 | 0.00985 |

| 38 | 0.004 | 0.1016 | 0.00811 |

| Metric 1 | .00394 | 0.1000 | 0.00785 |

| 39 | 0.0035 | 0.0889 | 0.00621 |

| 40 | 0.0031 | 0.07874 | 0.00487 |

6 AWG Wire Applications

6 AWG wire comes in various types based on insulation material, number of conductors, and specific design, each with its unique application.

- Car Audio Systems: Power cables for audio amplifiers, typically made from twisted fine copper strands.

- Vehicle Starting Applications: Connects the car battery to the starter motor.

- Marine cables: Used throughout shipboard electrical systems—including lighting, power distribution, and navigation systems—with exceptional resistance to salt spray corrosion and UV exposure.

- Building cables: Employed for residential wiring and connecting large household appliances.

- Welding cables: Supplied to construction sites and heavy equipment for power delivery. 6 AWG wire offers excellent flexibility alongside oil resistance, abrasion resistance, and low-temperature performance.

Frequently Asked Questions About 6 AWG Wire

Q1: Can I use 6 AWG wire to connect a 60-amp circuit breaker?

A: This depends on the wire type and the lowest-rated component in the circuit. If uncertain, use the most conservative (lowest) value.

Q2: What’s the difference between 6 AWG aluminum and copper wire? Can I use them interchangeably?

A: Absolutely not! Copper and aluminum wires differ significantly in current-carrying capacity, physical properties, and installation requirements. If you wish to substitute aluminum for copper, consult the NEC and 6 AWG current-carrying capacity chart to select a larger gauge aluminum wire. For example, to replace 6 AWG copper wire with aluminum, use at least 4 AWG or 2 AWG aluminum wire. If you are unfamiliar with electrical codes and circuit applications for different materials, for safety reasons, we strongly recommend using copper wire.

Q3: Why does my 6 AWG wire heat up when carrying high currents? Is this normal?

A: Slight heating of wires when carrying current is normal. However, wires becoming hot to the touch is an abnormal and dangerous sign. Reasons include:

- The most common cause is loose connections or gaps in terminals, increasing contact resistance. High current flowing through high resistance generates extreme heat, potentially causing fires.

- Overloading occurs when the current exceeds the safe capacity for the installation environment, causing the wire to overheat.

- Excessive voltage drop occurs when thin-gauge wires are used in long-distance circuits. Equipment draws more current to obtain sufficient power, causing wire overload.

Q4: Can 6 AWG wire be used in DC systems? For example, solar or RV applications?

Answer: Yes, and it’s very common. However, design considerations for low-voltage DC systems differ significantly from AC systems. In low-voltage DC systems, achieving the same power output requires higher current, necessitating thicker wire gauge to keep voltage drop within acceptable limits.

Q5: How is 6 AWG wire better than 8 AWG or 4 AWG?

A: This requires balancing your specific needs when selecting wire gauge. 6 AWG wire has lower resistance than 8 AWG, allowing it to carry higher currents and support more powerful devices. 4 AWG wire is thicker than 6 AWG, offering greater current capacity or longer power transmission distances, but it is also more expensive, heavier, and harder to install.

Conclusion

Selecting 6 AWG wire requires comprehensive consideration of load requirements, wire type, installation environment, and transmission distance. Cost is also a significant factor.

JinHai is not only a professional wire harness manufacturer but also offers a comprehensive range of products including wire harnesses, terminals, connectors, and wire supplies. By choosing JinHai as your partner, you will achieve optimal procurement costs and receive products of the highest quality.

Contact us immediately to learn how we can meet your cable and harness requirements. Follow us on Youtube .