New Requirements for New Energy Vehicle Connectors

- New Energy Vehicles: High Voltage Demands

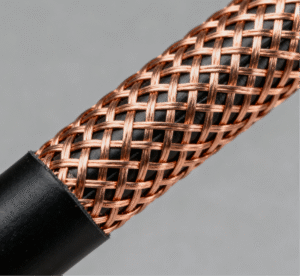

- New energy vehicle powertrains operate at voltages up to 800V, necessitating high-voltage wiring harness connectors. These connectors feature high voltage resistance and strong electromagnetic shielding.

- Intelligent Connectivity: Rapid Data Transmission

- Advanced driver assistance systems require automotive connectors with stable signal transmission, high transmission speeds, and robust shielding performance.

- Lightweighting Requirements

- For new energy vehicles, weight reduction is key to extending driving range. Wiring harness connectors must evolve toward lightweight designs while maintaining performance.

Custom Automotive Connectors: Technical Essentials

Connector performance hinges on design solutions, material selection, and manufacturing processes. When selecting manufacturers, customization capabilities are a critical consideration.

Design Elements of Custom Connectors

- Terminals: Transmit electrical signals.

- Housing: Protective layer for terminals.

- Sealing Ring: Enhances waterproof and dustproof performance.

- Latching Mechanism:

- Primary Latch: Ensures connector engagement with audible confirmation.

- Secondary Locking: Prevents terminals from detaching from the housing due to vibration or cable pulling.

- Misinsertion Prevention and Assist Structures:

- Misinsertion Prevention: Asymmetric shapes ensure correct insertion.

- Insertion/Extraction Assistance: Ensures smooth operation when connectors have numerous pins or high insertion/extraction forces.

Material Selection

Provides critical assurance for electrical connections during operation.

- Housing Material: Premium ABS plastic offering high-temperature resistance, corrosion resistance, and flame retardancy.

- Terminal Material: Copper alloy providing excellent conductivity and cost efficiency.

- Plating Material: Electroplated terminals deliver low resistance, oxidation resistance, and corrosion protection.

Testing Standards

Connectors undergo rigorous testing to meet global certification requirements.

- Electrical:

- Contact Resistance: Evaluates terminal connection quality.

- Insulation Resistance: Assesses insulation material performance.

- Withstand Voltage: Measures the connector’s voltage-carrying capacity.

- Physical:

- Insertion/Extraction Force: Ensures reliable connection.

- Terminal Retention Force: Force required to pull out terminals, preventing pin disengagement.

- Vibration Resistance: Maintains stable connection under automotive road vibrations.

- Mating cycles: Maximum number of insertions/removals under operational conditions.

- Environmental:

- Temperature cycling: Simulates temperature variations in operational environments.

- Salt spray test: Evaluates corrosion resistance in humid, saline conditions.

- Ingress protection rating: Verifies dust and water sealing performance.

- Chemical resistance: Withstands chemical agent corrosion.

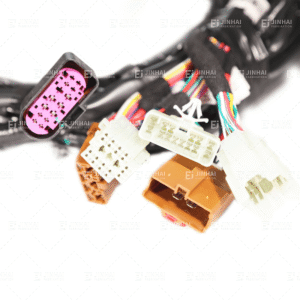

JinHai Professional Customization Process: From Design to Delivery

JinHai is a professional solutions provider with years of industry expertise, deeply understanding client needs in every project. JinHai maintains a closed-loop process from design to delivery, ensuring high-quality solutions for customers.

Step 1: In-depth Requirement Communication and Analysis

Our engineering team thoroughly discusses key factors including application scenarios, electrical loads, environmental constraints, driver cost targets, and project timelines.

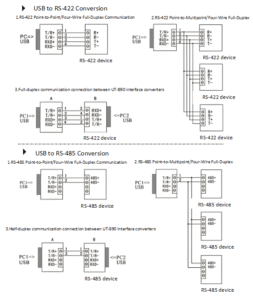

Step 2: Solution Design and Component Selection

Design solutions based on requirements, including preliminary selection of connector types, terminal specifications, cable materials, and protection ratings.

Step 3: 3D Modeling and Simulation Validation

Utilize CAD/CAE software for 3D modeling and virtual assembly, performing simulation analysis on critical performance metrics to identify and resolve potential issues before prototyping.

Step 4: Prototype Fabrication and Testing

Rapidly produce functional prototypes and subject them to comprehensive electrical, mechanical, and environmental testing in our ISO/TS 16949-certified in-house laboratory to ensure 100% compliance with design specifications and industry standards.

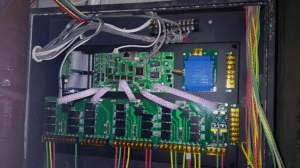

Step 5: Automated Mass Production and Quality Control

Proceed to batch production upon prototype validation. We possess automated capabilities for wire cutting, terminal crimping, assembly, and 100% electrical continuity testing, supplemented by visual inspection systems and pull-out tests.

Step 6: Delivery and Full-Cycle Technical Support

We offer flexible global logistics solutions and commit to providing continuous technical support and rapid response services throughout the product’s entire lifecycle.

JinHai: Your Trusted Custom Wire Harness and Connector Manufacturer

An outstanding manufacturer should possess the following attributes:

- Industry Certification Standards: ISO 9001, UL, RoHS, and other certifications.

- R&D and Testing Capabilities: Independent design team, mold development expertise, and fully equipped in-house laboratory.

- Automation Level: Automated processes ensure consistent product quality and stability.

- Project Experience & Success Stories: Proven track record in cutting-edge fields like new energy and autonomous driving.

- Supply Chain & Rapid Response: Partners with stable raw material supply and swift customer response mechanisms.

Conclusion

JinHai is dedicated to being a trusted global manufacturer of customized wire harness solutions. We not only possess advanced manufacturing equipment and rigorous production/process workflows but also strictly adhere to IATF16949 and ISO9001 quality management systems.

Choose JinHai to accelerate your project’s success—JinHai grows alongside your projects!