This guide will provide an in-depth analysis of trailer wiring harnesses by JinHai Wiring Harness Manufacturer, offering you a comprehensive reference for practical application and operational use.

Significance of Trailer Wiring Harnesses

Each wire within a trailer wiring harness serves a specific function. Proper installation ensures the safe operation of braking and lighting systems.

Application: Small household trailers use 4-pin flat connectors, while commercial and large trailers require connectors with more functional plugs.

Trailer Wiring Harness Color Code Standard

The color coding for trailer wiring harnesses follows the SAE (J2863) standardization for safety, efficiency, and interoperability. Below are the most common color codes and their functions:

| Wire Color | Pin | Function | Connector |

| White | 3 | Ground | All (4-way, 5-way, 6-way, 7-way) |

| Brown | 7 | Tail / Running Lights | All (4-way, 5-way, 6-way, 7-way) |

| Yellow | 1 | Left Turn Signal / Left Brake Light | All (4-way, 5-way, 6-way, 7-way) |

| Green | 4 | Right Turn Signal / Right Brake Light | All (4-way, 5-way, 6-way, 7-way) |

| Blue | 5 | Electric Brakes | 5-way, 6-way, 7-way |

| Red | 6 | Auxiliary Power or Reverse Lights | 6-way, 7-way |

| Black | 6 | Battery Charge / Auxiliary Power | 6-way, 7-way |

| Purple | 7 | Reverse Lights | 7-way |

Common Trailer Connectors: 4-Pin, 5-Pin, and 7-Pin

Depending on the complexity of the trailer’s functions, various connector standards are available on the market. Understanding their differences and appropriate applications is fundamental to selecting and installing the correct connector.

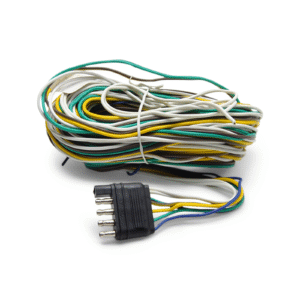

4-Pin Flat Connector

- Description and Application: The most basic and common trailer connector, controlling fundamental lighting functions. Primarily used for light trailers such as small utility trailers and motorboat trailers.

- Light Trailers (Without Brakes) = 4-pin flat connector.

- ① White = Ground

- ② Brown = Tail lights, side marker lights, and running lights

- ③ Yellow = Left turn signal and left brake light

- ④ Green = Right turn signal and right brake light

- Light Trailers (Without Brakes) = 4-pin flat connector.

5-Pin Flat Connector

- Description and Application: The 5-pin flat connector adds one additional pin to the 4-pin flat connector. The new functionality is used for trailers equipped with reverse or electric brakes.

- Traditional Trailer + Brakes = 5-Pin Flat Connector.

- Pins 1-4: Includes all functions of the 4-pin flat connector.

6-Pin Round Connector

- Description and Application: Commonly found on agricultural trailers, horse trailers, or some older camping trailers. Beyond basic lighting functions, it adds support for electric brakes and auxiliary power.

- Traditional Trailer + Brakes + Auxiliary Power = 6-Pin Round Connector.

- Pins 1-4: Incorporates all functions of the 4-pin flat connector.

- Blue: Electric brake controller output.

- Black or Red: 12V auxiliary power.

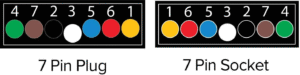

7-Pin Blade/Round Connector

- Description & Applications: The most versatile trailer connector, widely used for RVs, large trailers, heavy equipment trailers, and nearly all trailers equipped with electric brake systems.

- Traditional trailers adding brakes, auxiliary power, and/or backup lights = 7-pin connector.

- 1-4: Includes all functions of a 4-pin flat connector

- Blue: Electric brakes or other applications

- Black or Red: 12V auxiliary power

- Purple (or Gray): Reverse Lights

Hazards of Incorrect Trailer Wiring

Whether for commercial transport, weekend camping, or heavy-duty operations, ensuring a safe, reliable, and standardized electrical connection between trailers and tow vehicles is critical.

Incorrect wiring not only causes lighting failures and brake system malfunctions—making it illegal in many regions—but can also lead to serious traffic accidents.

Common Trailer Wiring Troubleshooting

After installation, trailer wiring harnesses may experience vibration-induced connector loosening, environmental corrosion, or aging. When trailer lights or brakes fail, systematically troubleshoot using these steps:

- Visual Inspection: Check connectors on both vehicle and trailer sides for visible damage, corrosion, or loose connections. Inspect wiring for fraying or cuts.

- Clean Connectors: Corrosion frequently occurs on connector pins. Disconnect the harness, clean all metal pins using a specialized electrical contact cleaner and small brush, reapply insulating grease, then reconnect.

- Verify Grounding: Ensure the white ground wire is securely attached to a clean, exposed metal surface.

- Inspect fuses and bulbs: Verify all trailer-related fuses and lights on the tow vehicle are intact.

Common Trailer Wiring Installation Errors

Avoid these frequent mistakes during DIY or non-professional installations:

- Poor ground connection: Randomly attaching the ground wire to a rusty bolt or painted surface causes electrical system malfunctions.

- Confusing wire functions: Guessing wire functions based on color when dealing with non-standard colors or old wiring harnesses. For example, reversing brake light and tail light wires prevents following vehicles from interpreting your signals correctly.

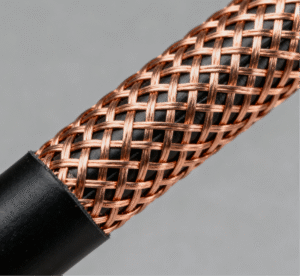

- Unsecured and unprotected wiring: Unsecured harnesses rub during travel, causing insulation failure that leads to short circuits or fires.

- Mismatched connectors: Connecting a 4-pin plug to a 5-pin connector creates incorrect circuit connections.

- Non-professional repairs: Wrapping aged, exposed wires with electrical tape allows liquid ingress, causing rapid corrosion and failure at connection points.

JinHai: Your OEM Trailer Wiring Harness Partner

Properly understanding and using trailer wiring harnesses as outlined in this guide effectively ensures driving safety and delivers a positive towing experience.

If you require trailer rewiring or industrial trailer wiring harness design, JinHai—as a professional OEM/ODM manufacturer—offers complete engineering solutions from concept to finished product. Following a rigorous customization process, we deliver limitless possibilities for your needs.

Contact us immediately to learn how we can meet your cable and harness requirements. Follow us on Youtube .