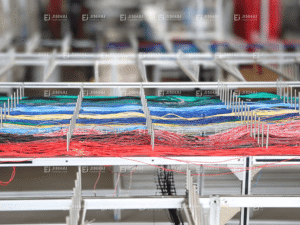

Technical Specifications for Wiring Harness Colors

International organizations have standardized automotive wiring harness colors to identify wire functions based on color.

Common Functions of Wiring Harness Colors

Low-voltage main circuit wire colors – Covering conventional electrical functions such as sensors, lighting systems, and chassis systems

- Blue/Yellow: Data transmission.

- Green: Control signals.

High-Voltage Safety Wire Colors – Focused on high-voltage components in new energy vehicles, including electric drive systems, battery systems, and charging systems

- Red: Positive voltage.

- Black: Negative or ground.

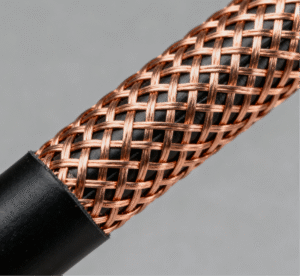

Wire Harness Color Coding Methods

Automotive wire color identification consists of a primary color and an accent color.

- Single-color wires: Entire wire is one color, e.g., pure red (RD), pure black (BK).

- Two-color wires: Primary color with one or more secondary stripes of different colors. E.g., red-based wire with white stripes is typically denoted as “R/WH” in wiring diagrams.

| Abbreviation | English | Abbreviation | English |

| Bk | Black | Bu | Blue |

| BN | Brown | CR | Clear |

| Dk Bu | Dark Blue | Dk GN | Dark Green |

| GN | Green | GY | Gray |

| LT Bu | Light Blue | LT GN | Light Green |

| OG | Orange | Pk | Pink |

| PL | Purple | RD | Red |

| TN | Tan | VI | Violet |

| WT | White | YL | Yellow |

Wire Harness Color Codes by Country

Wire harness color codes are not universal and vary across different national standards. We will analyze the primary standards of Japan, North America, the European Union, and China in detail.

Japanese Standard (JASO D611): JIS C 3406 “Low-Voltage Cables for Automobiles” focuses on defining which colors of wires transmit or perform specific functions.

- Red: Power supply (similar to global standards).

- White: Ground wire (differs from North America’s black).

- Green: Signal wires (e.g., instrument panel controls).

- Yellow: Hybrid/electric vehicle high-voltage lines.

North American Standard (SAE): SAE J1128 defines a recommended color system influencing automotive and electronic applications in the North American market.

- Red: Ignition or positive power source.

- Black: Ground wire or negative terminal.

- Yellow: Constant power line, airbag system (SRS), or turn signal.

- Brown: Commonly used for lighting circuits like tail lights and license plate lights.

- Blue: Antenna or amplifier signal.

European Automotive Wiring Standard (DIN & LV): DIN 72551-7 is the core specification for low-voltage cable colors and markings.

- Brown: +12V power supply (ISO 6722).

- Blue: Headlights or auxiliary equipment.

- Green/Yellow stripe: Ground (mandatory per DIN VDE 0293).

- Gray: Sensor or data lines.

Chinese Standards (GB/T & QC/T): QC/T 414-2016 defines combination rules for primary and secondary color systems, providing clear guidance for distinguishing specific functions within complex wiring harnesses.

- Red: Power supply (compliant with ISO standards).

- Black: Ground wire.

- Blue: Communication lines.

- Yellow-green stripe: Ground wire in industrial equipment (similar to EU standards).

Automotive Wiring Harness Color Code Reference Chart

| Country/Region | Power | Ground | Signal/Data | Key Standard |

| North America | Red | Black | Blue/Yellow | SAE J1128, USCAR |

| European Union | Brown | Green/Yellow | Gray/Blue | DIN 72551, ISO 6722 |

| Japan | Red | White | Green | JIS C 3406 |

| China | Red | Black | Blue | GB/T 19666 |

Can automotive wiring harnesses be DIY-ed based on color codes?

Arbitrarily DIYing automotive wiring harnesses based on color codes is not permissible and may pose the following risks:

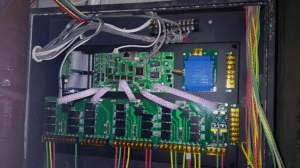

- Damage to electronic components: Incorrectly connecting a 12V power line to a 5V sensor can instantly burn out the sensor or even the connected engine control module (ECU).

- Malfunction: Incorrect wiring can cause vehicle system disruptions.

- Electrical fires: Incorrectly grounding high-current lines or connecting them to low-capacity circuits may cause wires to overheat, ultimately triggering short circuits and fires.

Why do such significant safety issues arise despite adhering to standard color specifications?

- Lack of unified national standards: Different countries establish varying standards.

- Model year variations: Wiring harness color codes may change even within the same vehicle model across different production years.

- Multiplexed systems: Colors cannot uniquely define the protocol data on a wire, as wires may carry multiple complex digital signals.

Obtain the official service manual or wiring diagram specific to the vehicle model and year to identify the wire harness color, circuit number, and precise function for each pin.

Function of Automotive Wire Harness Colors: Troubleshooting

Color codes serve as vital identifiers during fault location and resolution. They help you quickly pinpoint the physical wire requiring testing by cross-referencing circuit diagrams with the actual vehicle. Subsequent multimeter testing enables precise fault confirmation.

Common Questions

Can General Motors and Ford wiring harness color codes be interchanged?

General Motors (GM) and Ford Motor Company, as global automotive giants from different countries, operate as two entirely independent systems. Each maintains its own mature yet incompatible engineering standards, including wire harness color codes.

Summary

Automotive wire harness color codes appear as a simple standardized color system, yet they represent a field rich in complexity.

This in-depth analysis aims to establish a correct and safe understanding framework:

- No universal standard exists: Manufacturers in each country operate under their own systems.

- Schematics are the definitive reference: Always obtain official schematics for your vehicle’s make, model, and year from authorized sources before performing any electrical repairs.

- Purpose of wire colors: Use standardized color codes to quickly identify wire issues, then pinpoint the exact problem with professional tools like a multimeter.

Contact us immediately to learn how we can meet your cable and harness requirements. Follow us on Youtube .