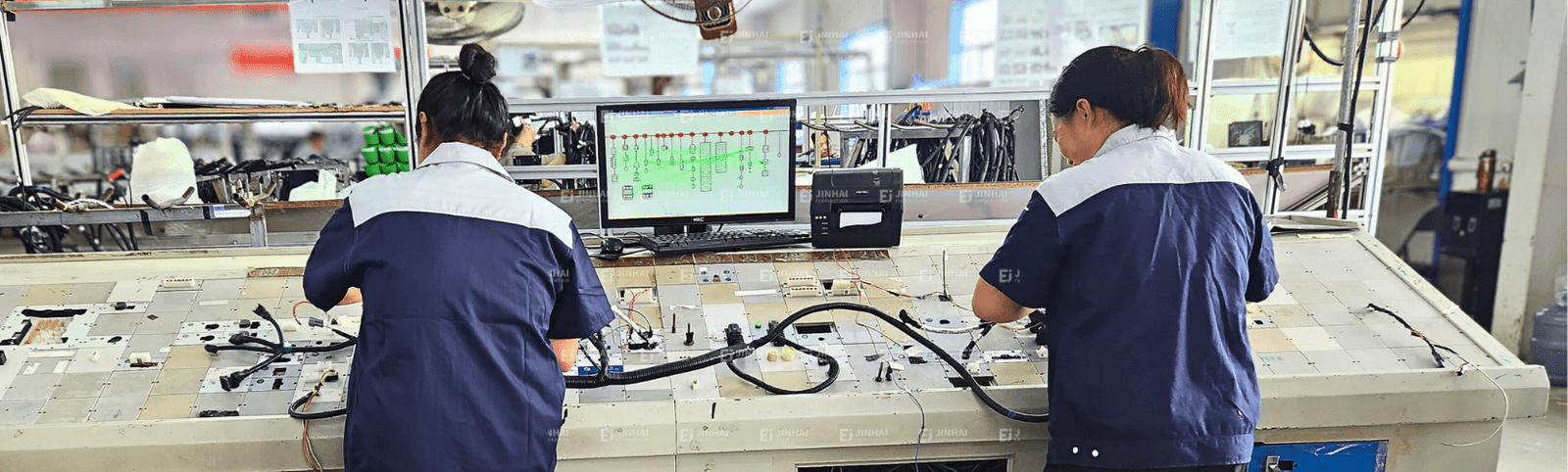

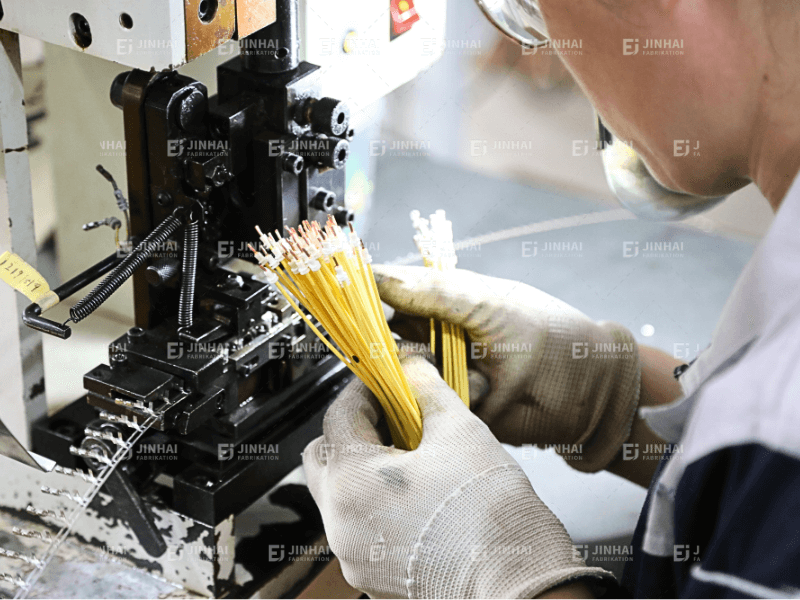

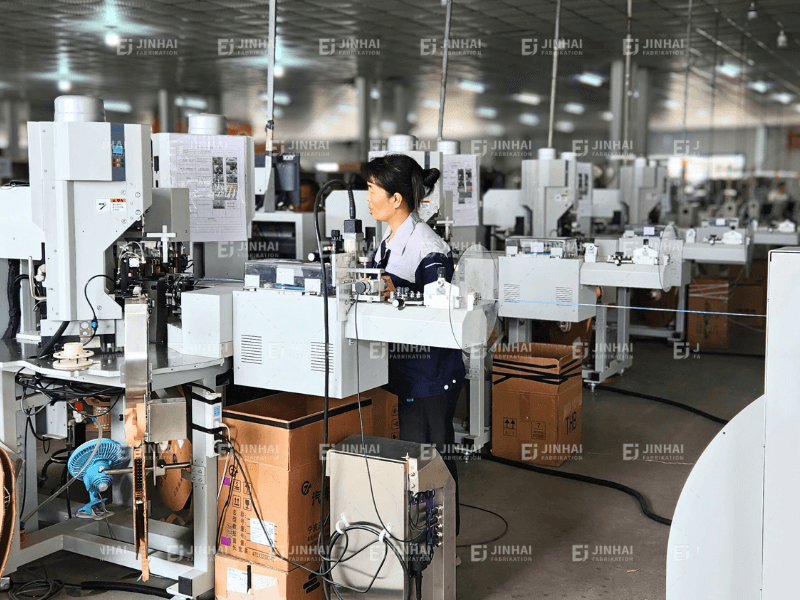

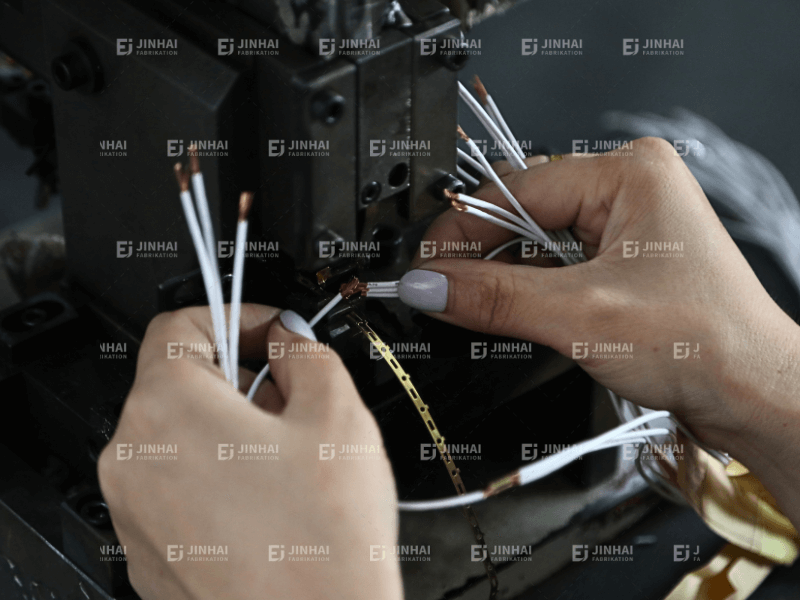

JinHai Factory Scale

Number of Employees

800+

Production Bases

Three major production bases

Factory Area

10000m²

Benefits of working at JinHai

Paid Annual Leave

Our employees enjoyed a ten-day vacation last year and also received normal work income.

Commuter Bus

Employees can take the company's shuttle service during work hours to reduce commuting pressure

Annual Team-building Activities

Work and play are balanced. After a busy quarter, the company organizes exciting team-building activities to promote teamwork.

Career Development Planning

We organize core employees to undergo technical training every year to help them sort out their career plans and grow with the company.

Our job vacancies

System Engineer

Construction and optimization of the quality system

1.Responsible for the release, update, maintenance, disposal and archiving management of the company’s quality system documents.

2.Supervise the implementation of documents of each department of the company and record and archive work.

3.Responsible for sorting out and compiling factory-level systems and processes.

4.Improvement and optimization of system operation.

5.Responsible for preparing annual audit plans and audit plans.

Internal and external audit management

6.Lead the implementation of audits and follow up on the completion of corrective actions.

7.Implementation, recording and follow-up management of management reviews.

8.Receive external audit plan and confirmation of audit preparation work.

9.Organize, distribute and follow up on the completion of improvements of external audit issues.

Defective product management

10.Responsible for the receipt and disposal of defective raw materials.

11.Responsible for feedback and follow-up of supplier issues.

12.Responsible for supplier claims and daily evaluation data maintenance.

Inspection/experiment management

13.Responsible for the preparation and updating of raw material inspection specifications and records.

14.Calibration of inspection tools and execution of MSA.

15.Assist in the implementation of product audits and full-size inspections.

16.Enter daily data reports in quality control.

Internal and external audits

1、Responsible for the preparation of internal and external audit materials and organizing the audit;

2、Analyze, rectify and follow up on problems found in internal and external audits.

3、Responsible for mid-term quality control during the development of new projects;

New project management

4、Responsible for early quality development, establishing and tracking project quality objectives, and participating in quality gate reviews;

5、Participate in reviewing DFMEA, drawings, PFMEA. Identify product and process KPC;

7、Prepare process inspection, shipment inspection, GP12 inspection instructions, CP;

8、Review product inspection plans, follow up on the progress of pre-production inspection and acceptance, and develop inspection instructions and MSA analysis;

Archiving management of quality documents and materials

9、Track quality issues during product trial production and manage quality data statistics and analysis files;

10、Participate in early project change meetings and monitor the effectiveness of change implementation.

11、Provide quality inspection training to operators and inspectors;

12、Responsible for the preparation, revision and review of new project and incoming material quality documents;

13、Establish file and record ledgers, and conduct unified management of the numbering and use of files and records;

14、Check the use and effective control of documents and records.

Responsible for receiving customer information

1.Responsible for receiving customer requirements and converting them into internal documents for distribution.

2.Responsible for receiving customer complaints and complaints.

Responsible for organizing and following up on improvements

3.Responsible for organizing various departments to analyze anomalies.

4.Fumai prepares and responds to customer improvement reports.

5.Responsible for following up and improving verification results.

Management of annual reports

6.Responsible for preparing full-size inspection report and organizing its implementation as planned.

7.Responsible for coordinating with Anwen on the execution of annual type tests.

Handling of defective products

8.Responsible for the return and exchange management of abnormal products for customers.

9.Responsible for the analysis and confirmation of defective products reported by the after-sales market.

Cooperate with the audit work

10.Together with the project manager, welcome customer/system audits and implement improvement results on quality management issues.

Other

Complete other tasks assigned by superiors.

Product process quality control

1.Control the quality of products in production and ensure that the products flowing out are qualified.

2.Assessment indicators: Whether there are any quality complaints about the products sent to customers.

Determination and disposal of defective products

1.Clarify the criteria for determining defective products and the reasonable handling of defective products.

2.Assessment indicators: Whether defective products can be detected and dealt with in a timely manner.

Responsible for the production, labeling and effectiveness control of product samples

1.Make product samples, post labels, and ensure that product samples are qualified.

2.Assessment indicators: Accuracy of sample production.

Verification of failed parts by production line workers

1.Whether the failed parts on the line can be identified.

2.Assessment indicators: Timeliness of handling failed parts.

Responsible for the periodic verification and effectiveness management of all measuring tools

1.Carry out periodic inspections on all heavy tools to ensure they can be used normally

2.Assessment indicators: whether the equipment is inspected and managed according to the prescribed time.

Other

Complete other tasks assigned by superiors.

Product process quality control

1.Control the quality of products in production and ensure that the products flowing out are qualified.

2.Assessment indicators: Whether there are any quality complaints about the products sent to customers.

Determination and disposal of defective products

1.Clarify the criteria for determining defective products and the reasonable handling of defective products.

2.Assessment indicators: Whether defective products can be detected and dealt with in a timely manner.

Responsible for the production, labeling and effectiveness control of product samples

1.Make product samples, post labels, and ensure that product samples are qualified.

2.Assessment indicators: Accuracy of sample production.

Verification of failed parts by production line workers

1.Whether the failed parts on the line can be identified.

2.Assessment indicators: Timeliness of handling failed parts.

Responsible for the periodic verification and effectiveness management of all measuring tools

1.Carry out periodic inspections on all heavy tools to ensure they can be used normally

2.Assessment indicators: whether the equipment is inspected and managed according to the prescribed time.

Other

Complete other tasks assigned by superiors.